Hi everyone,

I've been out of the country since November 2nd doing some volunteer work in a Spiritual Organization that help the underprivileged in South Africa.

In my spare time I continue my research. I've been experimenting with Coil Flyback Feedback since I believe it could greatly improve electric motor efficiency and could possibly be applied in transformers which would make a solid state device (no moving parts).

I have made a crude permanent magnet motor (pulse motor) to which I demonstrate the energy saving effect once you capture and re-input the flyback to the pulse motor.

I was originally trying to send it back to the same coil but I lack electronics skills to do it correctly. Isolation of the power source, coil, MOSFET switches are a pain. Timing is another problem. After over 30 hours and all kinds of blown devices I had to come up with an idea that didn't need all these components just for proof of concept.

I'll let the more talented in electronics come up with a circuit if they feel the pursuit is worthy after seeing my simple proof of concept video.

When first trying to make the feedback circuit I was using a hard drive disk platter and bearing assembly as magnet rotor but when I couldn't get it to work I had to come up with another idea. What I came up with was to mount the HD plater to a shaft of a 12vdc motor I salvaged from an old VCR and send the flyback to it which would Isolate it from the coil and the energy should assist the pulse motor to turn faster.

Well the results are better then I expected!... the pulse motor goes from 200ma with a 6.24vdc input with no flyback to 50ma @ 6.37vdc with flyback feedback at the same RPM.

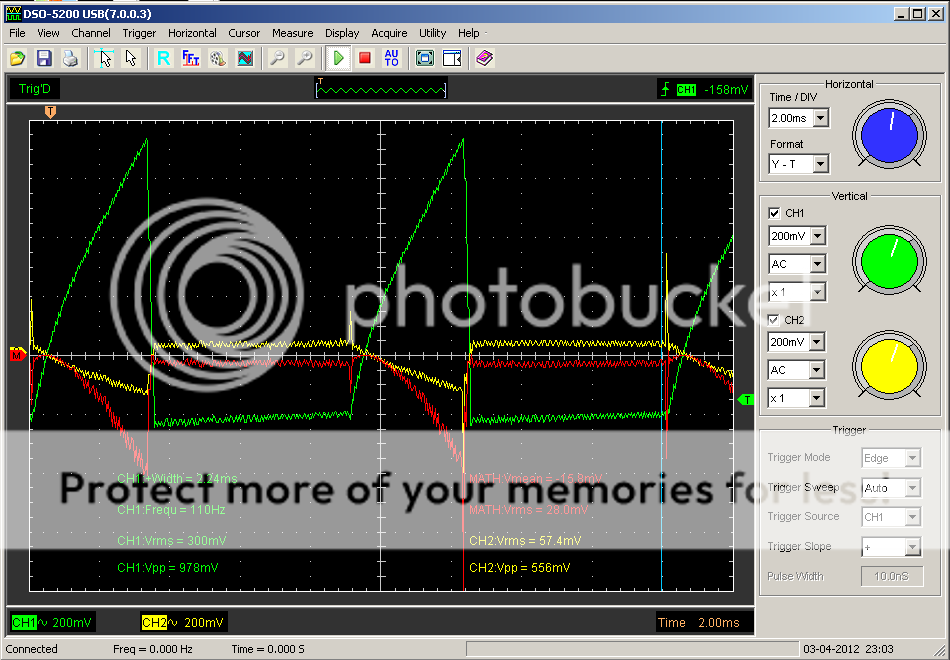

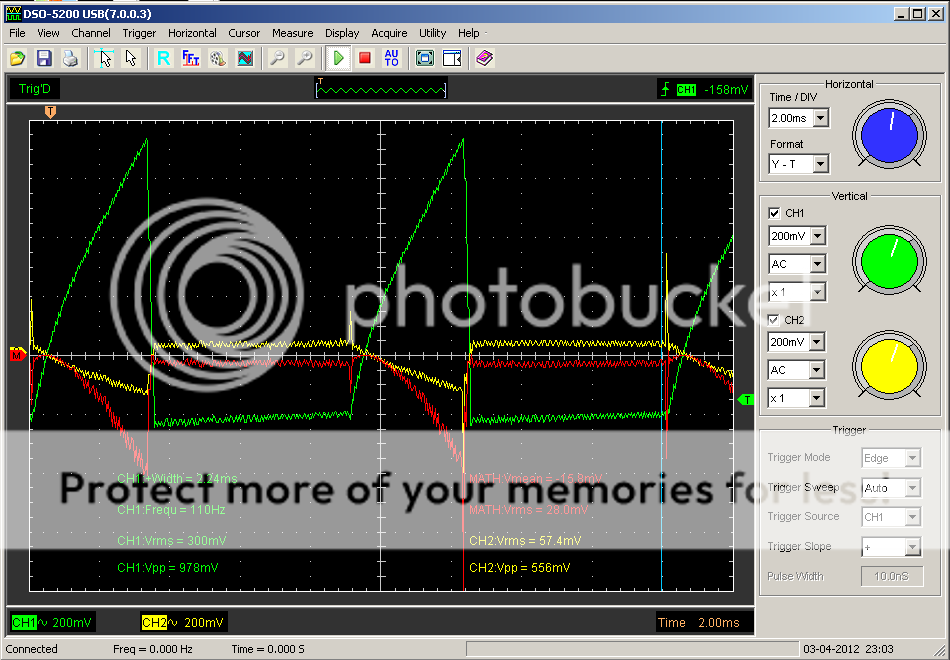

In the video demo I use my oscilloscope to match up the timing (RPM) before and after. So don't go crazy on the scope shots you see in the video as it was used mostly for that purpose. The probe is across the coil. The scope data is not stable as there are to many peeks to display correct Frequency, Period and so on. So I made some extra scope shots (below) with a standard voltage and current setup through a 1 Ohm resistor. First shot is No flyback feedback with input at 6.24vdc @ 200ma and the next is with flyback feedback feedback at 6.37vdc @ 50ma. just like it was done in the video. The rotor has 4 magnets so with the new scope shots below the Frequency is 110Hz so we divide it by 4 (magnets) = 27.5 turns per second x 60 (seconds in a minute) = 1,650 RPM the magnet rotor is turning.

Link to video demo: Motor Coil Flyback Feedback Effect test 1 - YouTube

I have not seen or noticed any topic on recirculation flyback back in a motor, so to me it looks promising and would like the input of those who are knowledgeable. If I'm missing something or not fully understanding the present electric motors please feel free to enlighten me.

I'm also very open to circuit suggestions that could send the flyback back to the coil but in the same current direction the On pulse did. This could be done during the off time and that energy could be part of the next pulse which should greatly assist the motor.

So to be clear on what I would like the motor and circuit to do, is for the magnet to naturally attract to the coils core (no power), once at center of the core the coil is hit with the energy of the flyback collected in a capacitor of the previous pulse and the balance to top off the cap can be regulated coming from the battery or energy input.

I welcome any other suggestions

Thanks for sharing

Luc

I've been out of the country since November 2nd doing some volunteer work in a Spiritual Organization that help the underprivileged in South Africa.

In my spare time I continue my research. I've been experimenting with Coil Flyback Feedback since I believe it could greatly improve electric motor efficiency and could possibly be applied in transformers which would make a solid state device (no moving parts).

I have made a crude permanent magnet motor (pulse motor) to which I demonstrate the energy saving effect once you capture and re-input the flyback to the pulse motor.

I was originally trying to send it back to the same coil but I lack electronics skills to do it correctly. Isolation of the power source, coil, MOSFET switches are a pain. Timing is another problem. After over 30 hours and all kinds of blown devices I had to come up with an idea that didn't need all these components just for proof of concept.

I'll let the more talented in electronics come up with a circuit if they feel the pursuit is worthy after seeing my simple proof of concept video.

When first trying to make the feedback circuit I was using a hard drive disk platter and bearing assembly as magnet rotor but when I couldn't get it to work I had to come up with another idea. What I came up with was to mount the HD plater to a shaft of a 12vdc motor I salvaged from an old VCR and send the flyback to it which would Isolate it from the coil and the energy should assist the pulse motor to turn faster.

Well the results are better then I expected!... the pulse motor goes from 200ma with a 6.24vdc input with no flyback to 50ma @ 6.37vdc with flyback feedback at the same RPM.

In the video demo I use my oscilloscope to match up the timing (RPM) before and after. So don't go crazy on the scope shots you see in the video as it was used mostly for that purpose. The probe is across the coil. The scope data is not stable as there are to many peeks to display correct Frequency, Period and so on. So I made some extra scope shots (below) with a standard voltage and current setup through a 1 Ohm resistor. First shot is No flyback feedback with input at 6.24vdc @ 200ma and the next is with flyback feedback feedback at 6.37vdc @ 50ma. just like it was done in the video. The rotor has 4 magnets so with the new scope shots below the Frequency is 110Hz so we divide it by 4 (magnets) = 27.5 turns per second x 60 (seconds in a minute) = 1,650 RPM the magnet rotor is turning.

Link to video demo: Motor Coil Flyback Feedback Effect test 1 - YouTube

I have not seen or noticed any topic on recirculation flyback back in a motor, so to me it looks promising and would like the input of those who are knowledgeable. If I'm missing something or not fully understanding the present electric motors please feel free to enlighten me.

I'm also very open to circuit suggestions that could send the flyback back to the coil but in the same current direction the On pulse did. This could be done during the off time and that energy could be part of the next pulse which should greatly assist the motor.

So to be clear on what I would like the motor and circuit to do, is for the magnet to naturally attract to the coils core (no power), once at center of the core the coil is hit with the energy of the flyback collected in a capacitor of the previous pulse and the balance to top off the cap can be regulated coming from the battery or energy input.

I welcome any other suggestions

Thanks for sharing

Luc

Comment