Core

@wantomake,

Project sounds interesting, this motor/generator is one of the best designs out there. They can be applied to so many things. Make sure to burn the motor really well and remove the commutator before burning!!! The shaft can be hammered off...I put the core on PVC pipe so the shaft could be hit out. It didnt take tooo much effort. When It gets down in the core, I used an old screw driver to hit it the rest of the way out.

warrensk

Announcement

Collapse

No announcement yet.

My Asymmetric Electrodynamic Machines

Collapse

X

-

Thanks

Thanks for the reply Warrensk,Originally posted by warrensk View PostHey wanttomake!

I went to home depot or lowes...any hardware store... and I got a 3/8ths inch bolt thing...And by bolt thing I mean a long shaft without a head on it...so it is pretty much a long 3/8ths in shaft...I then put the motor core on that, had a bunch of 3/8in washers in between the motor core and the commutators. I think I used like 15 washers on each side...Then comes the commutators and then I used a 3/8th in nut on each end to press the whole thing together...This worked pretty well for me. Make sure you leave enough room for the wires (space between commutator and motor core) Some laminations from the core may need to be removed...

Hope this helps, Ive made the 1016s before...I wound that motor 2 times, the 1020s are the same construction but have 20 poles instead of 16

Warrensk

I looked up the specs after the last post. The 1020 seems to have more space to work with on each end. My problem is the machine to press the core off in order to do what you did.

I'm trying to build this again to use as a smaller scale of the Lockridge device project. This device is best motor/generator I've ever put a fluke meter on. Ufopolitics is big help and support with attributes out of this world.

Again thanks. And thank you Ufo for all of this.

wantomake

Leave a comment:

-

Commutator....

Hey wanttomake!

I went to home depot or lowes...any hardware store... and I got a 3/8ths inch bolt thing...And by bolt thing I mean a long shaft without a head on it...so it is pretty much a long 3/8ths in shaft...I then put the motor core on that, had a bunch of 3/8in washers in between the motor core and the commutators. I think I used like 15 washers on each side...Then comes the commutators and then I used a 3/8th in nut on each end to press the whole thing together...This worked pretty well for me. Make sure you leave enough room for the wires (space between commutator and motor core) Some laminations from the core may need to be removed...

Hope this helps, Ive made the 1016s before...I wound that motor 2 times, the 1020s are the same construction but have 20 poles instead of 16

Warrensk

Leave a comment:

-

My1016

Hey Warrensk,Originally posted by warrensk View PostHey UFO,

Ive got another pair of MY1020's coming...I just realized all the new concepts are for a 2 stator system...I will wait patiently to see your results with the 4 stator/4brush system...A ten pole 4 stator system can be done too. Let me know if it can be applied simply to 4 stators...

Could I wind it just as I wound the 16 pole but with all north coils and only 10 poles?

Or I could wind groups of coils in between where the pair would have occupied? Would the angle be alright?

Warrensk

I've got a pair of my1016's and was wondering how you got the commutator on to the larger shaft in the front of the motor?

Did you mill it down or what? I know the front and back shafts are different sizes.

Or are the my1020 made different?

Thanks,

wantomake

Leave a comment:

-

It Will...

Hello Warrensk,Originally posted by warrensk View Post@UFO,

I was thinking that when I was looking at the diagram...It looks like the coils will always be opposite...at least for even numbered poles with 4 stators...The 2 stator is more like tesla's design...Let me know if you think this design will work with 4 stators...otherwise I will work on getting those magnets switched around.

Warrensk

Yes, it will work on Four Stators, of course...We just need to make certain tests to see which way would be more successful in performance.

I will upload it later on

Regards

Ufopolitics

Leave a comment:

-

4 stator....?

@UFO,

I was thinking that when I was looking at the diagram...It looks like the coils will always be opposite...at least for even numbered poles with 4 stators...The 2 stator is more like tesla's design...Let me know if you think this design will work with 4 stators...otherwise I will work on getting those magnets switched around.

Warrensk

Leave a comment:

-

Not winding yet

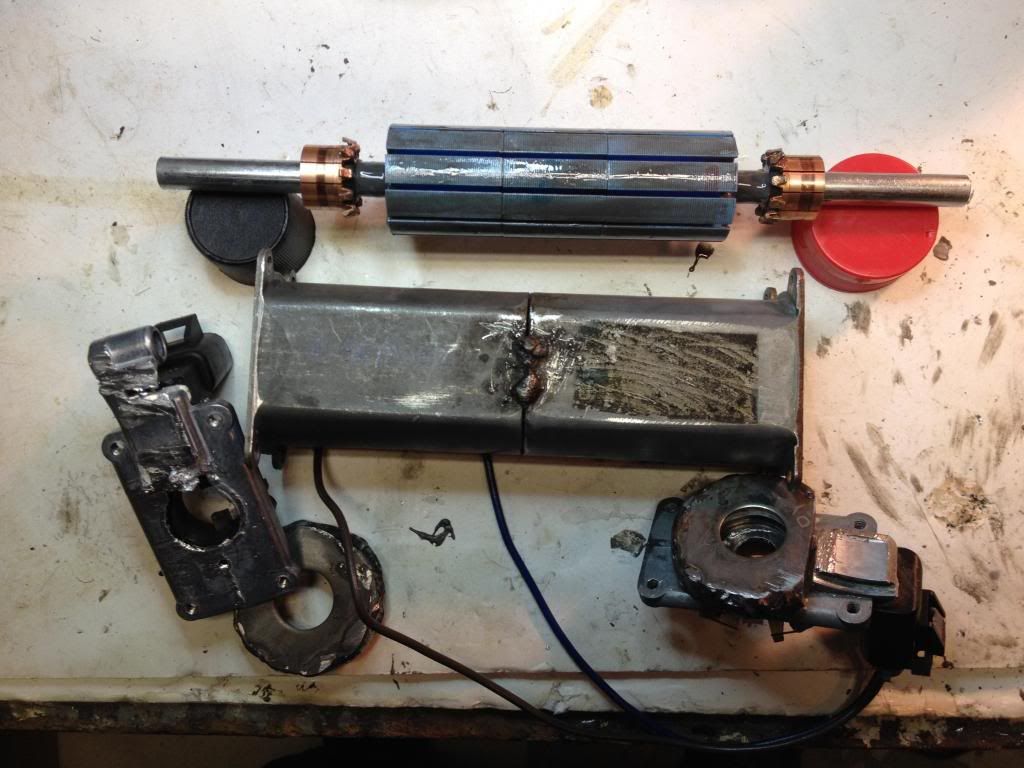

Still gotta fasten those bearing housings on the motor endplate. Darn brush wire came loose, look like it was soldered to the exterior connector. Man this one wasnt welded, like it was repaired. Hope it holds, cant braze it now.

I think the rotor looks nice...

Last edited by sampojo; 04-14-2014, 02:59 AM.

Last edited by sampojo; 04-14-2014, 02:59 AM.

Leave a comment:

-

IMPORTANT!: Groups are "ONE WAY" Winding.

Hello to All,

One thing I want to share and that is:

VERY IMPORTANT!: Groups are "ONE WAY" Winding.

[IMG] [/IMG]

[/IMG]

I have written about this previously...but I wanted to dedicate just one post so it gets Special ATTENTION.

It doesn't matter Rotation sense or Groups "Numbering"...We must wind Groups in "Advance Mode", meaning, that next group ALWAYS is AHEAD of previous wound...never wind them "Backwards"...or there would be a lot of air gaps between first and last coils of two groups.

Look at picture above...I have chosen to show G1 and G10...and that is PROGRESSIVE/ADVANCED WINDING.

If I wind G1, then G2...We will have air gaps between first Coil from G1 and last of G2.

When you wind progressively, coils will fit perfectly tight one on top of the other, just like One Single Coil...and that is the way they should look.

[IMG] [/IMG]

[/IMG]

Actually Coils do NOT look like straight lines...but like picture above...

And this is not only about a better way to fit make tight this type of windings mechanically...but, it has to do also with Magnetic Fields projection, strength, induction, etc... resulting in overall Performance of Machine.

And...finally...one way that you can NEVER DO this winding...is to do G1...then G8...then G16...meaning "alternatively" or randomly.

Thanks

UfopoliticsLast edited by Ufopolitics; 04-14-2014, 02:14 AM.

Leave a comment:

-

Hello Warrensk,Originally posted by warrensk View PostHey UFO,

Ive got another pair of MY1020's coming...I just realized all the new concepts are for a 2 stator system...I will wait patiently to see your results with the 4 stator/4brush system...A ten pole 4 stator system can be done too. Let me know if it can be applied simply to 4 stators...

Could I wind it just as I wound the 16 pole but with all north coils and only 10 poles?

Or I could wind groups of coils in between where the pair would have occupied? Would the angle be alright?

Warrensk

If you just wind that Diagram "AS IS" but with All North Coils, instead of North South...that "thing" won't move when energized, even if shaft attached to a working Asymmetric Imperial... ...just kidding...and exaggerating

...just kidding...and exaggerating

Take a look just at South Coils and make them Blue...or North...when you energize those Pairs all North...the existing Norths will favor rotation by repulsion just like before...BUT Norths replacing South will be attracted to South Stator Fields Center...generating two Forces perfectly opposite to rotation...it will stay in same place...just humming.

Regards

Ufopolitics

Leave a comment:

-

Hello Sam,Originally posted by sampojo View PostHi ufo , all

I assume we use the same length wire, resistance per group.

Nope...We need to create strong Magnetic Fields on EACH Coil, so, minimum we need to turn is at least five times per coil.

The "mechanical" advantage of using Groups is to be able to add a bit more turns then have more resistance at Group than we had on Pairs...

The difference is much less in Groups than in Pairs Sam...Groups are using more slots, spreading outwardly more even than Pairs.But when winding outwardly stacking the coils the outer coils being wider may take fewer winds and less turns per sub coil. In other words we don't try to compensate this detail and do something like maintain the same number of winds on a coil?

thanks,

Sam

Don't worry about so many details...just wind the darn thing and test it Man!!...

I thought you were uploading videos by now...

Regards

Ufopolitics

Leave a comment:

-

Question on changing coil sized in the group winding

Hi ufo , allOriginally posted by Ufopolitics View PostHello to All,

The Ten poles as seen on last video was wound as a P-10 (Ten Pairs):

[IMG] [/IMG]

[/IMG]

I made it out of my Sullivan Starter Motor for Gas R/C Helicopters, converted to Asymmetrical previously...Now I am going to re-wind it according to 10 Groups, NOT Pairs...so is a "G-10":

[IMG] [/IMG]

[/IMG]

Don't get scared, it may look complicated but it is NOT...is just to "see" what we are doing here...

In Pairs Winding, each Coil wrapped around Three Poles, so Six (6) for Pair...and now in Groups we are comprehending same Total of Six (6) Poles for each Group.

Every Group have Four (4) Coils, instead Pairs having Two (2) Coils...so, we fit Four Coils into Six Poles by Overlapping every pole.

We are using exactly SAME Commutator Element as on Pairs.

We would be able to fit more copper, more turns, as also leave less air gaps, plus other attributes related to performance...

The way I recommend to wind this is to start like P1 in Blue...then winding next P10, then P9 and so on...so the displacement of wires sets better into each other overlapped Coils Group slots.

Regards

Ufopolitics

I assume we use the same length wire, resistance per group. But when winding outwardly stacking the coils the outer coils being wider may take fewer winds and less turns per sub coil. In other words we don't try to compensate this detail and do something like maintain the same number of winds on a coil?

thanks,

Sam

Leave a comment:

-

Moving stators wont be easy...

Hey UFO,

Ive got another pair of MY1020's coming...I just realized all the new concepts are for a 2 stator system...I will wait patiently to see your results with the 4 stator/4brush system...A ten pole 4 stator system can be done too. Let me know if it can be applied simply to 4 stators...

Could I wind it just as I wound the 16 pole but with all north coils and only 10 poles?

Or I could wind groups of coils in between where the pair would have occupied? Would the angle be alright?

WarrenskLast edited by warrensk; 04-13-2014, 03:19 PM.

Leave a comment:

-

20 to 5...

Hello Warrensk,Originally posted by warrensk View PostHello UFO...so in my burn of the two MY1020 motors I forgot to pull the commutator off and I destroyed one of them...I got to thinking, could I reduce the number of poles to 5? This would make it easier to make a commutator for the build. Let me know!

Well, you've got a choice to make there friend...however, the Five Pole RS Type is a Two Stator...is it going to be simple to swap magnets to make it N-N-S-S?

For sure it would be a nice Scaling of the Five Pole small one...and watch if Attributes remain as well...plus the extra two brushes could be used to see output at those angles.

However, I will be doing a 20 pole, but using Groups...20 Groups, converting the BOSCH I have. I need to see how it behaves with a Four Brush/Four Stator System...so we could move up into bigger outputting plus stronger machines...that still accelerate under load.

Regards

Ufopolitics

Leave a comment:

-

20 pole to a 5 pole?

Hello UFO...so in my burn of the two MY1020 motors I forgot to pull the commutator off and I destroyed one of them...I got to thinking, could I reduce the number of poles to 5? This would make it easier to make a commutator for the build. Let me know!

Leave a comment:

-

Hello IG,Originally posted by interestedngreen View PostI could not find a 10 pole 2 stators motor to wind using the group winding method. But I have a 12 pole, 12 comm elements, 2 stators motor that I would like to wind instead. Mr. Ufopolitics, Sir, can the illustration of G-1O in post #6490 apply to my 12 pole 2 stators rewind? Thanks in advance.

Just get my 12 Pole N-S Pairs, 2 Stators...and replace them by groups...just like I did with P10...

Then show us what you have...

Ufopolitics

Leave a comment:

Leave a comment: