I tried editing the earlier post twice. but don't know why. it's not taking.

I just recollected what UFO said

Kumar,

Just finish the two pairs left...

Means, I need not think too much of it

So going ahead rewinding the same way. but with some more extra paper in order not to short

25 SWG - 18 mts - nearly 2 ohm res as meter reads.

25 SWG - 18 mts - nearly 2 ohm res as meter reads.Once again thanks a lot Kogs for the support.

Regards and Namaste

Kumar

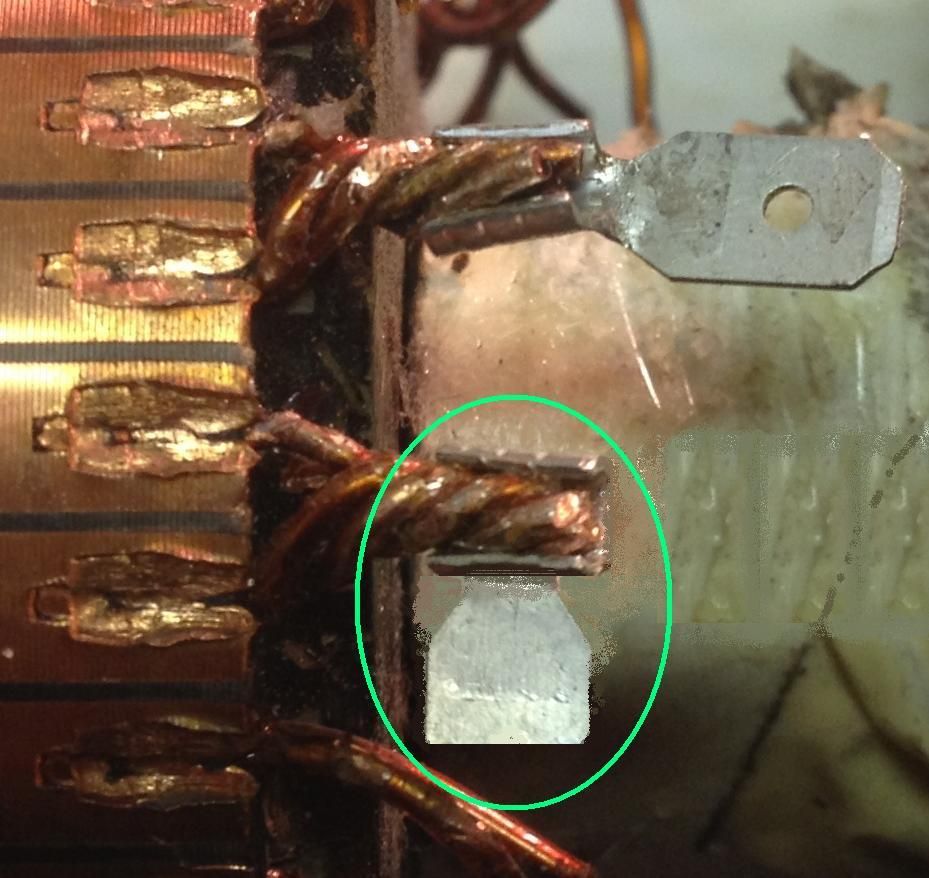

as I understood I shorted two coils with the armature core

as I understood I shorted two coils with the armature core  . Pair 3 and Pair 13 shorted. I took necessary care to avoid this situation by keeping the poly paper sheet that the professional winders keep. I kept on checking the poles till I completed ten pairs winding. Till then it was very much alright.

. Pair 3 and Pair 13 shorted. I took necessary care to avoid this situation by keeping the poly paper sheet that the professional winders keep. I kept on checking the poles till I completed ten pairs winding. Till then it was very much alright.

), i found smoke from the rotor. I stopped feeding that voltage and currant to armature. This time I increased the wire length ( and thus the no. of turns) and also the res. hoping that I could run it on 230 v 4 amp.

), i found smoke from the rotor. I stopped feeding that voltage and currant to armature. This time I increased the wire length ( and thus the no. of turns) and also the res. hoping that I could run it on 230 v 4 amp.

- again only to understand it doesn't work

- again only to understand it doesn't work

[/IMG]

[/IMG]

...Yeah, not seconds, until I install the Imperial Asymmetric...

...Yeah, not seconds, until I install the Imperial Asymmetric...

WOoooooow. That thing is too cool, is it yours? When are you going to install your motor in it?

WOoooooow. That thing is too cool, is it yours? When are you going to install your motor in it?

Leave a comment: