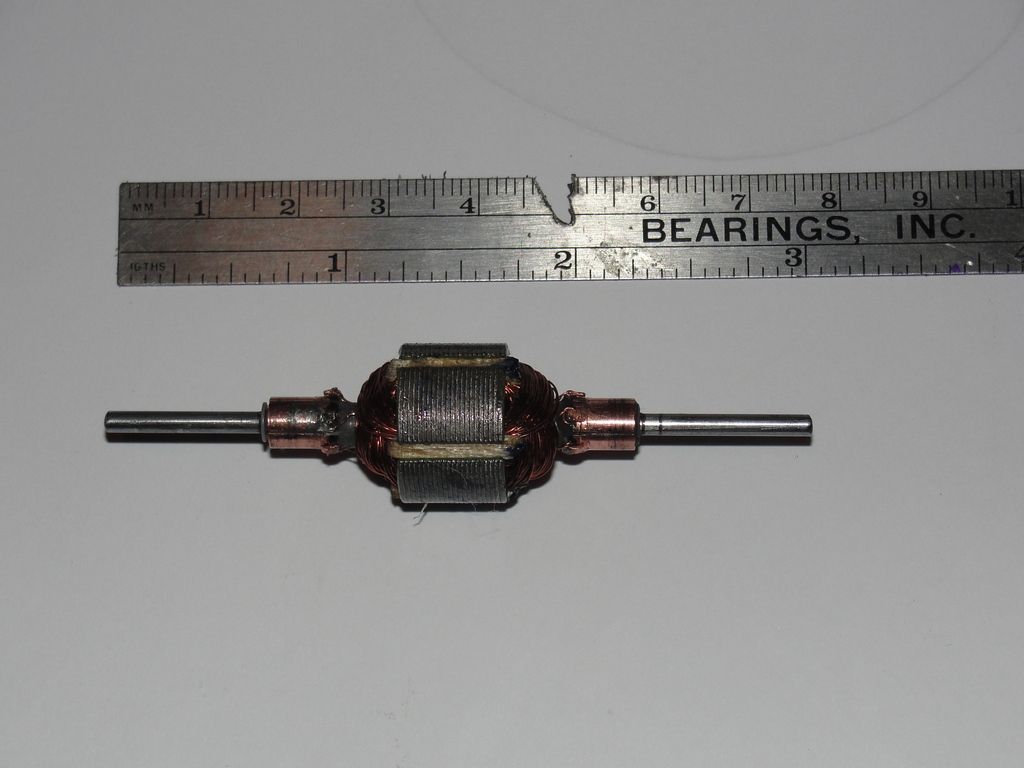

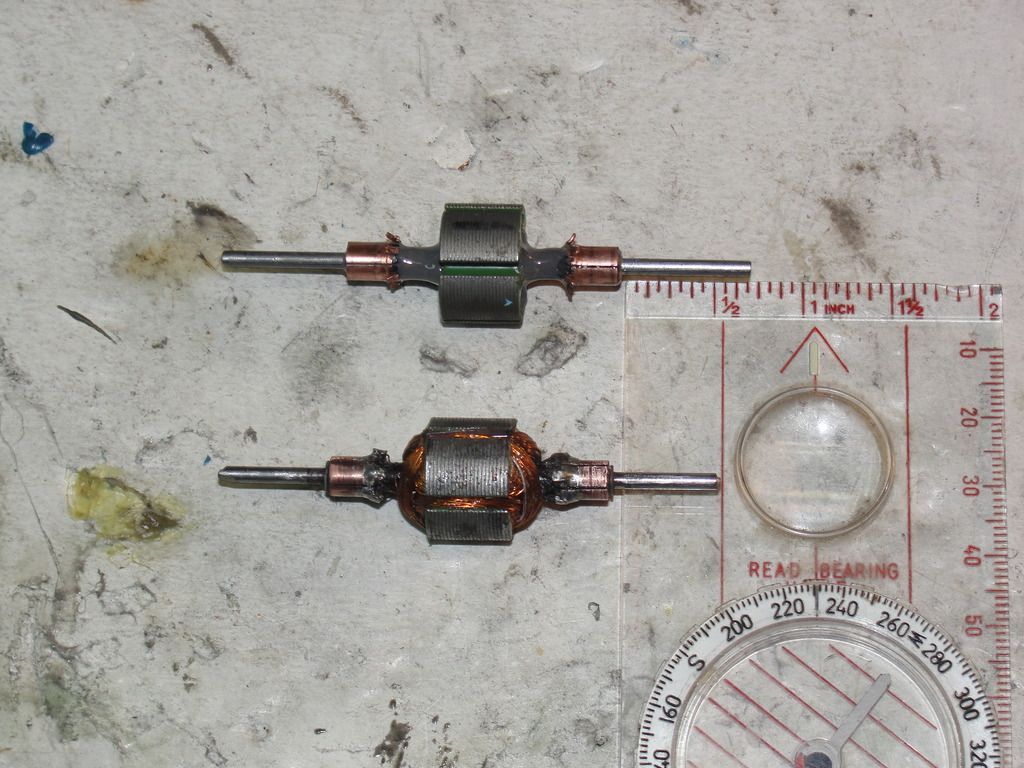

Took a chance and ran it with only wooden hedges for a quick test, maybe got 29000 rpm on just one brush set. Here it is with a coat of epoxy on the windings. Needs to cure.

Dreaming up a test rig... want to use a panel ammeter rather than a digital multimeter.

Good night

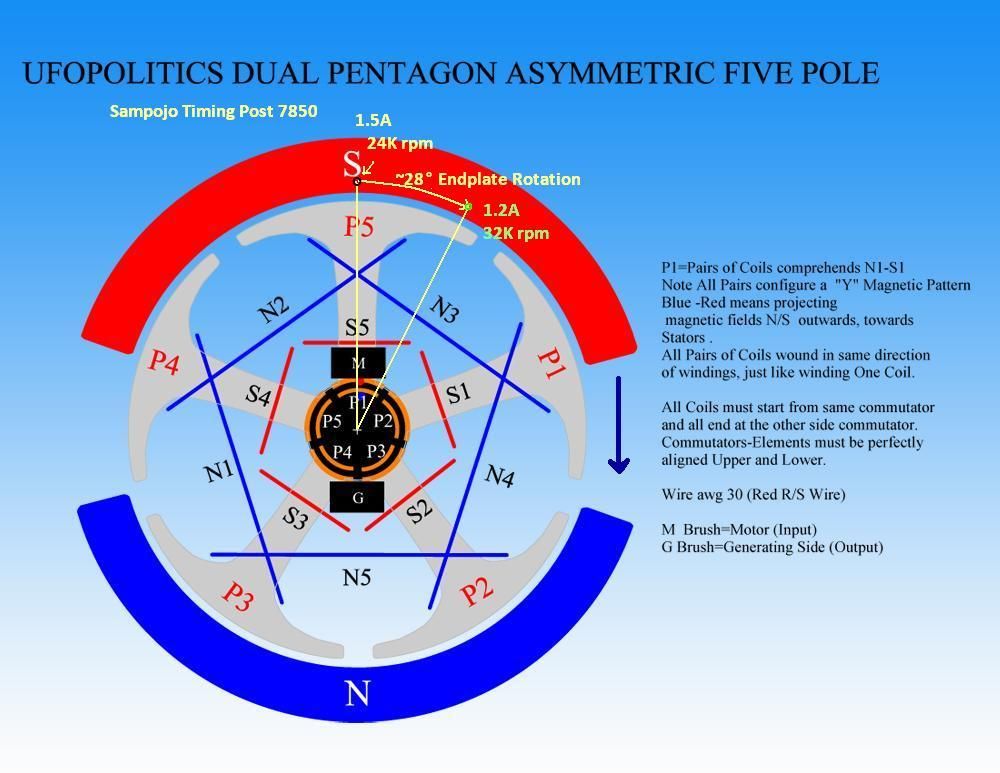

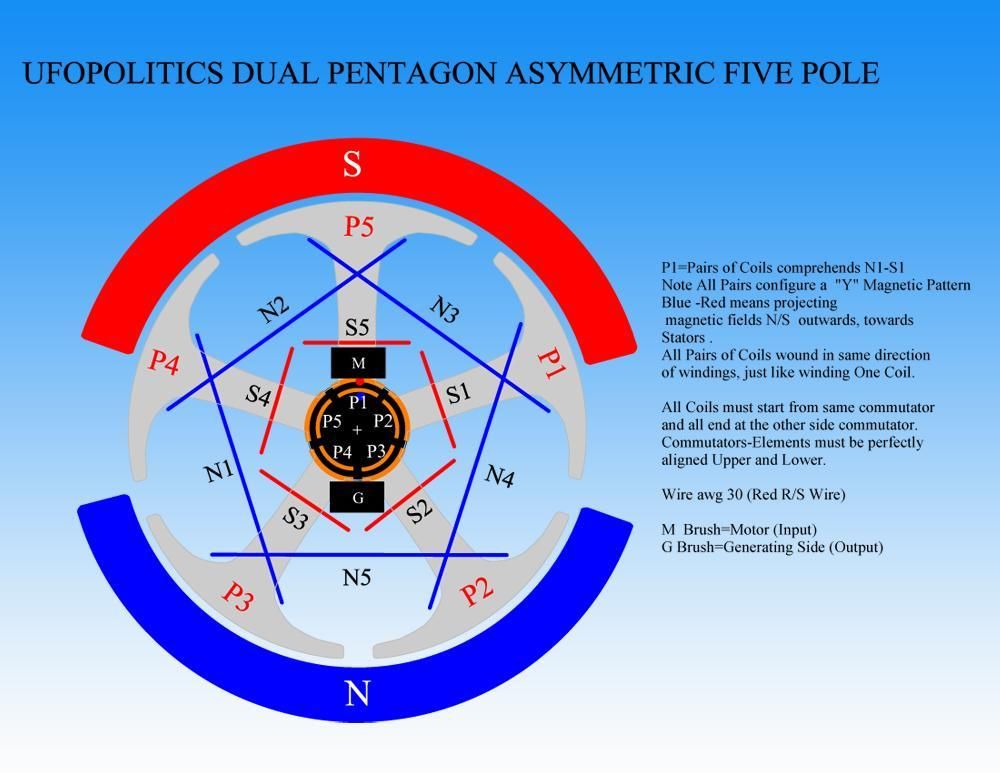

, well then, that opens a design possibility where these little motors could be designed a little like the forklift motors, say a much lower coil resistance around .1 ohm, not 1 ohm, if my logic is correct. This motor would of course be some kind of monster

, well then, that opens a design possibility where these little motors could be designed a little like the forklift motors, say a much lower coil resistance around .1 ohm, not 1 ohm, if my logic is correct. This motor would of course be some kind of monster !!!! RPM??? Motor stresses could be incredible. 12v might be too much... Or never run it unloaded

!!!! RPM??? Motor stresses could be incredible. 12v might be too much... Or never run it unloaded  !!

!!

Leave a comment: