Howdy UFO, all,

RE: open to comments. Could the following explain your and HR's diff. views

due to a conflict of terminology?

Assuming a 1" wide comm. element and 1" thick brush. Also assume the dia

or circumfrence as such to require 10 deg rotation to cause 1" 'travel' on comm.

surface. It will take 10 deg rotation to bring brush's first contact to center the brush

upon the comm. element. It takes 10 deg more to turn the switch off. Thus the 'coil' or

pole is energized for 20 deg. of rotation.

Please forgive if I'm all confused also.

Also, UFO, I've sent you an email re: another matter.

Regards to all....jw

Announcement

Collapse

No announcement yet.

My Asymmetric Electrodynamic Machines

Collapse

X

-

Misrepresentation

Hi UFO

I agreed to let other members respond and comment on this post, but I didn't agree to be misrepresented.

Being true to my word, I shall wait a day or two (longer if you advise) before commenting.

Happy Hunting

mark

Leave a comment:

-

About Angles of Interaction Facts...

Hello to All,

Mark (Hunting Ross) and I have been discussing lately on a very important issue, which directly relates to setting the correct timing on Asymmetrical Machines. The main side is that Mark kept adding the two angles involved at each interaction , which are brush/commutator segment Plus(+) Magnetic Interaction Angle taking place at energized coils and Stators Fixed Angles, all within the same rotation shaft, and taking place at the same exact time.

It is very well known that Symmetric Motors, which is where we base our Asymmetric Designs structures, always keep the Commutator Diameter smaller than Rotor Diameter.This is done in order that commutation sweep Time will always be contained within each interaction angle Time.

In very few motors I have seen a Commutator where its diameter is almost the same as the rotor diameter. However, they do exist and mostly are used as heavy torque motors.

In high speed motors the commutator is much more smaller than rotor diameter.

But, what I have never seen...is a Commutator which is much bigger than rotor size.

When we start analyzing the length of each coil circumference related to commutator segment circumference...then we see a major difference, where coils are always bigger than segments.

Above is something that must of Us know, however, I consider it very important at time to analyze deeper this topic.

Now, getting into the discrepancy issue between Mark and I:

[IMG] [/IMG]

[/IMG]

Above we have FIG 1 which is a simple Rotor with just one Commutator Segment attached by connecting wires to the Coil.

On FIG 2 We see the same structure, but reflecting the angles participating in this single Interaction. I have encircled the Brush and the Comm Segment defined by Angle A, within a Red Circle, which is the Switch, (in our case with Asymmetrical Motors, is understood we have SW 1 & SW 2, one on top of the other when looking on a top view like shown).

Then we have the Magnetic Interaction 1, from Coil and section of Core, that is within Angle B into a Blue Circle. And it is understood as well that Coils interact with the Stators Angles, not shown for simplicity of just rotor analysis.

What Mark has been doing all this time...is adding Angles A+B+C, to be considered as a "Total Sweep Angle" to be reflected upon the Magnetic Stators fixed Angles from center to center, which could be 180║ for a two stator motor...or 90║ for a four stator motor.

I said He can not add None of this Angles, and force them to be fitted within the Stators Angles, resulting in very small "left over" degrees to conduct our timing. For example He calculated somehow that Sampojo had a Total Left Over Angle of just 2║ to effect timing...and this is very wrong!

He can not include the Switching Interaction Angle sweep within the Stators Angles of strength from center to center, just because carbon brush and copper segment-contact plate from commutator are not dependent from absolutely any magnetism restriction, nor magnetic interaction at all.

[IMG] [/IMG]

[/IMG]

On FIG 3 above I have radically set the Red Circled Switch exactly at 180║ apart from Coil Magnetic Interaction in Blue Circle...So here, according to Mark, We will have to add A+B...PLUS the long Angle C...to then "fit it" within our Stators Center to center angles....and of course...we may run way over or maybe a couple of degrees off to "play" with timing...

This Concept of adding Angles from Switch to Coils is absolutely wrong!!

The only thing that limits/dictates the positioning of our whole Commutating Switch is our Symmetric Motors designs and their Structures, as if brushes could be moved freely, or are completely fixed...and also dictated by our common sense to use less connecting wire length, when winding in order to search for the closest segment that allows Us to be within the structure spec's.

Finally on FIG 4 is the way we must understand the relation between Switching and Magnetic Interaction Angles, based on Two(2) simple facts:

1- The Fact both interactions take place within the same exact Time.

2- That Always Angle A is going to be smaller than Angle B (A < B).

Concluding here, I tell You that, regardless of the Switch positioning, the MAIN part that we must be sure off, check and re-check... are the Magnetic Interactions taking place between Energized Coils and Permanent Stators turn On and Off at the specified angles spec's displayed here by me all along this Thread.

The Switching Circuit, defined by the connecting wires from start coil #1, the Brush and the commutator segment connected to Coil 1 .. could be absolutely anywhere in its circumference as you guys please to do...and please, do not consider this angle for any means, except it just do its job of turning On and Off based on the proper Magnetic Bisecting Angles.

Finally, if We feel comfortable to do so...We could have each segment hooked within the Coils sweep Angle "physically"...just like we are looking in FIG 4, which case I have suggested on previous posts to Mark...asking him if now...would he 'still' add angles.

I know, I am sure off...that this Topic tends to a lot of confusion...I have been trying for the best way to explain/show with the appropriate Graphics this two Interactions relationship taking place...in the best of my ability to keep them as simple as possible.

I have previous experience of several years with Internal Combustion Engines...when it comes to set timing between several turning shafts and sprockets and chains with guide adjustment, etc,etc... where all must be aligned to reach the same exact point in time to fire the correct cylinder chamber at the right, perfect stage...Therefore, I really see this single shafted Machine, as not that complicated when we compare them. However, I can understand for others who do not have even experience with electrical motors... it could bring a lot of confusion.

If You All have any questions about above post, please do not hesitate to make your point, concerns or doubts.

Regards to All

Ufopolitics

EDIT 1:

Now, another thing I must add here, is the fact that after you have decided where to set your switch position...then by moving JUST the Brush, you will be either retarding or advancing the whole process.

So, one thing is to move the WHOLE SWITCH and another completely different is JUST TO MOVE BRUSHES.

The Switch Positioning is something we decide when we are setting our motor structure, before even starting to wind Pair Coils number one (1)Last edited by Ufopolitics; 05-17-2015, 04:34 PM.

Leave a comment:

-

Hi UFOOriginally posted by Ufopolitics View PostI understand...that "we" have a disagreement on this subject/topic. However, I hope you understand this 'specific topic' refers to a very important part of Asymmetric Machines, which involves Timing, and as Garry Childers has proven through his latest testings, timing is of the complete essence to achieve a top performance operation on this kind of machines.

Therefore, I am hoping you understand I can not just leave it like this...meaning in a complete "limbo" or abandon it completely...without getting to the bottom of all this controversy that has led to so much fuel to fire the delusional guy on the Hijacked Thread from this one.

So, I took my time (once again) to render some CAD work where I will be posting to the whole Thread...so, please, since we have 'no agreement here'...allow others to render their opinion.

I understand your point and agree others should 'render their opinion'. It is disappointing to me that no one has done so.

For many, the timing issue is decided by the OEM brush settings and therefore deciding on the best wind to fit the circumstance and maintain close proximity to the NSB for the 'ON' time.

Timing has also been taken to mean 'tuning' where fine adjustment is achieved to look for the perfect setting.

It might not be obvious to onlookers that the discussion so far has focused on the 'timing' in order to establish the fundamental geometry of the chosen wind and thereby determine if there is any angle left for fine 'tuning'.

I look forward to your next illustration which hopefully covers both aspects and I especially look forward to anyone commenting on the same.

Happy Hunting

mark

Leave a comment:

-

Hello Mark,Originally posted by HuntingRoss View PostAs agreed UFO, we both have nothing further to add to this particular topic.

We will have to respectfully disagree.

Happy Hunting

mark

I understand...that "we" have a disagreement on this subject/topic. However, I hope you understand this 'specific topic' refers to a very important part of Asymmetric Machines, which involves Timing, and as Garry Childers has proven through his latest testings, timing is of the complete essence to achieve a top performance operation on this kind of machines.

Therefore, I am hoping you understand I can not just leave it like this...meaning in a complete "limbo" or abandon it completely...without getting to the bottom of all this controversy that has led to so much fuel to fire the delusional guy on the Hijacked Thread from this one.

So, I took my time (once again) to render some CAD work where I will be posting to the whole Thread...so, please, since we have 'no agreement here'...allow others to render their opinion.

Appreciate that!

Sincerely

Ufopolitics

Leave a comment:

-

As agreed UFO, we both have nothing further to add to this particular topic.Originally posted by Ufopolitics View PostMark, I have to start from the very beginning...

In your whole response, you deleted the essential part from my previous post:

[/COLOR][/B]

Time= On Both Angles displacement.

Space= On both Angles displacements.

It don't matter that commutator segment is ahead of coil interact area....one could move ahead of the other...however they traveled the same EXACT TIME AND SPACE from the total 360║.

Mark, I do not need to make pieces out of cardboard...I have 3D Animated CAD Software, transparencies, exotic materials, illuminations, textures etc...it all runs within the same time track...there is absolutely nothing better than this CAD and the Real Model to work on.

Respectfully

Ufopolitics

We will have to respectfully disagree.

Happy Hunting

mark

Leave a comment:

-

Mark, I have to start from the very beginning...Originally posted by HuntingRoss View PostI truly do understand the mechanics of this operation. It pains me that with all that has been written and drawn on this topic we can not come to understand each other.

Your comment above is agreeing with me, yet you think I still don't understand.

In your whole response, you deleted the essential part from my previous post:The coils are energised. The shaft with the commutator and the coils, all together, move from connection to disconnection. I understand that. The quantity of that movement is described by the width of the commutator segment plus the width of the brush. They all move together that distance together. And those coil bisectors (pairs and groups) move that distance because they all move together.

Originally posted by Ufopolitics View Post

1-Now, can you realize this is a single operation?

2-Can you realize they take place within the same, exact Time?

3-Can you realize the sweeping angles from both, commutator segment and Coils wound at Armature spins together, since they are attached at the same rotating Shaft?

Time= On Both Angles displacement.

Space= On both Angles displacements.

It don't matter that commutator segment is ahead of coil interact area....one could move ahead of the other...however they traveled the same EXACT TIME AND SPACE from the total 360║.

If I made a 120║ cardboard cut out representing the angle between the two coil bisectors of a 12 pole 4 pole pairs wind and glued that to a shaft and made that shaft rotate 57║ representing the connection to disconnection of the brush with the comm segment. I wouldn't be surprised that I could fit a 13║ piece of cardboard in what was left of the semi circle that would ultimately limit the rotation of this shaft. I would be surprised when it didn't all fit together if that 13║ piece of cardboard was supposed to be 25║.

I agree that there is no more mileage in discussing this point. It seems neither of us are convinced by the others persuasion.

Correct. It wasn't as clear as it could be. In the context it seemed OK. Being I was talking about the connection to disconnection. If that confused anyone, apologies for that.

Keep Hunting

mark

Mark, I do not need to make pieces out of cardboard...I have 3D Animated CAD Software, transparencies, exotic materials, illuminations, textures etc...it all runs within the same time track...there is absolutely nothing better than this CAD and the Real Model to work on.

Respectfully

Ufopolitics

Leave a comment:

-

I truly do understand the mechanics of this operation. It pains me that with all that has been written and drawn on this topic we can not come to understand each other.Originally posted by Ufopolitics View PostP1 is turning On, Coils are energized, then the magnetic interaction starts moving the shaft until it disconnects commutator segment from brush.

Your comment above is agreeing with me, yet you think I still don't understand.

The coils are energised. The shaft with the commutator and the coils, all together, move from connection to disconnection. I understand that. The quantity of that movement is described by the width of the commutator segment plus the width of the brush. They all move together that distance together. And those coil bisectors (pairs and groups) move that distance because they all move together.

Because. In one of your schematics, which seems a very long time ago now, you showed P1 just connecting with P2 still fully connected and concluded the timing was good. When in fact P2 still had to move (with everything else together) to disconnect which moved the P2 bisector past the ideal OFF angle.Originally posted by Ufopolitics View PostThen why in this World do we need to add brush sweeping angle plus coils sweeping angles like if they occur at different Times/Angles?...Or delayed by any 'unknown' reason?...

If I made a 120║ cardboard cut out representing the angle between the two coil bisectors of a 12 pole 4 pole pairs wind and glued that to a shaft and made that shaft rotate 57║ representing the connection to disconnection of the brush with the comm segment. I wouldn't be surprised that I could fit a 13║ piece of cardboard in what was left of the semi circle that would ultimately limit the rotation of this shaft. I would be surprised when it didn't all fit together if that 13║ piece of cardboard was supposed to be 25║.

I agree that there is no more mileage in discussing this point. It seems neither of us are convinced by the others persuasion.Originally posted by Ufopolitics View PostWhat I see is that... until you do not see this...We can not keep discussing about further alignments in your motor.

Correct. It wasn't as clear as it could be. In the context it seemed OK. Being I was talking about the connection to disconnection. If that confused anyone, apologies for that.Originally posted by Ufopolitics View PostAbove you wrote "connected commutator"...but, connected comm. what?...segment?...or whole comm.?...think you missed the word right?

Keep Hunting

mark

Leave a comment:

-

Time and Space...

Mark,

Just looking at P1 segment with brush making contact from on to off position is enough to see how this works...We do not need P2 for below explanation...

The operation is simple, we just need to look at your nice close up CAD from FIG 1...let's play it in slow motion.

P1 is turning On, Coils are energized, then the magnetic interaction starts moving the shaft until it disconnects commutator segment from brush.

1-Now, can you realize this is a single operation?

2-Can you realize they take place within the same, exact Time?

3-Can you realize the sweeping angles from both, commutator segment and Coils wound at Armature spins together, since they are attached at the same rotating Shaft?

Then why in this World do we need to add brush-segment sweeping angle plus coils bisector sweeping angle like if they occur at different Times/Angles?...Or delayed by any 'unknown' reason?...

Even after all my previous posts...and diagrams...you have not been able to see that this is a single timed operation?

They both take exactly the same Time and Rotation Space from the complete 360║ spin.

Again, the positioning of the whole switch, could be anywhere, but, as long as it is attached to the same shaft...where all coils are attached...We are talking the same exact Consumed Time for both Operations.

What I see is that... until you do not see this...We can not keep discussing about further alignments in your motor.

Above you wrote "connected commutator"...but, connected comm. what?...segment?...or whole comm.?...think you missed the word right?Thank you Sam. As UFO has already remarked, that makes your brush approximately 27║ wide.

That means your connected comm has to sweep approximately 36 + 27 = 63║ from connection to disconnection. Working with a combined 'ideal ON / OFF' angle of 25║, gives you 88║. Thats leaves 2║ for timing adjustments.

Related to Sampojo...please, do not tell him to add both angles Mark...he is enough confused here, because of previous attacks from this delusional guy...Let allow him to answer my previous post addressed to him first, to see if he understood everything I wrote....and if so...I rather wait to see His results after he test his ten pole motor.

Sincerely

UfopoliticsLast edited by Ufopolitics; 05-16-2015, 09:18 PM.

Leave a comment:

-

Just for clarity. I have no argument with Sam or his motor.Originally posted by Ufopolitics View PostThen join the arguments Mr. Hunting Ross...

My involvement on this specific topic is to tidy up unfinished business relating to incorrect comments relating to 4 pole pairs pertaining to one of my historic CAD schematics.

There has been to date, a robust discussion on the subject. And I'm certainly not 'falling out' with anyone over the subject.

In fact. With my last post on this subject, if this doesn't settle the matter there is no reason to go any further with it. It can not be put any simpler.

Happy Hunting

mark

Leave a comment:

-

The working assumption is your 10 pole motor has 10 comm segments at 36║ each, not 20 @ 18║ each.Originally posted by sampojo View PostIf a brush here would be 36║ wide, it would be twice as wide as a comm segment.

Thank you Sam. As UFO has already remarked, that makes your brush approximately 27║ wide.Originally posted by sampojo View PostIf it helps to find out if this design has any inherent good qualities, my brushes are about 3/4's the width of the comm segments.

That means your connected comm has to sweep approximately 36 + 27 = 63║ from connection to disconnection. Working with a combined 'ideal ON / OFF' angle of 25║, gives you 88║. Thats leaves 2║ for timing adjustments.

UFO has added a useful image of the importance for alignment of the double comm rotors, so accuracy is paramount when there is only 2║ to play with.

Happy Hunting

mark

Leave a comment:

-

[IMG] [/IMG]

[/IMG]

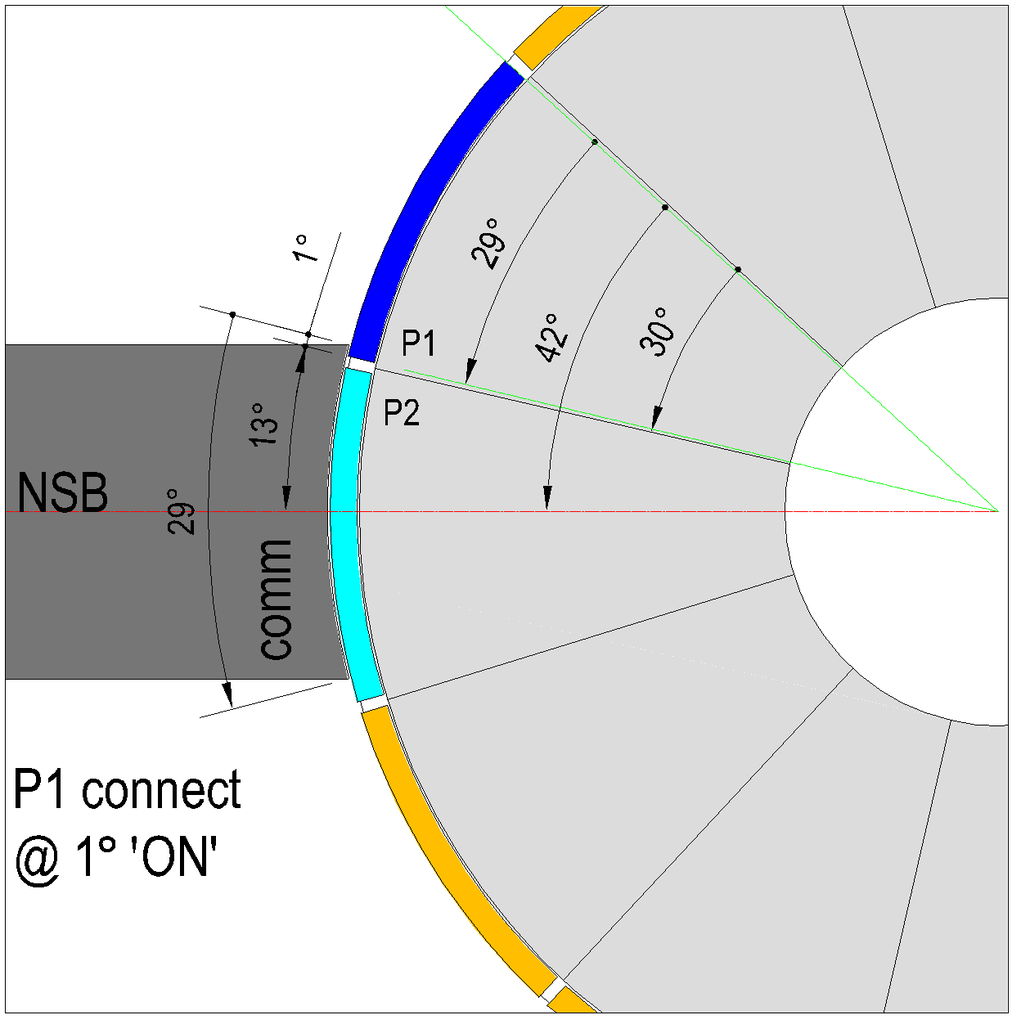

Image 1 - P1 connecting.

[IMG] [/IMG]

[/IMG]

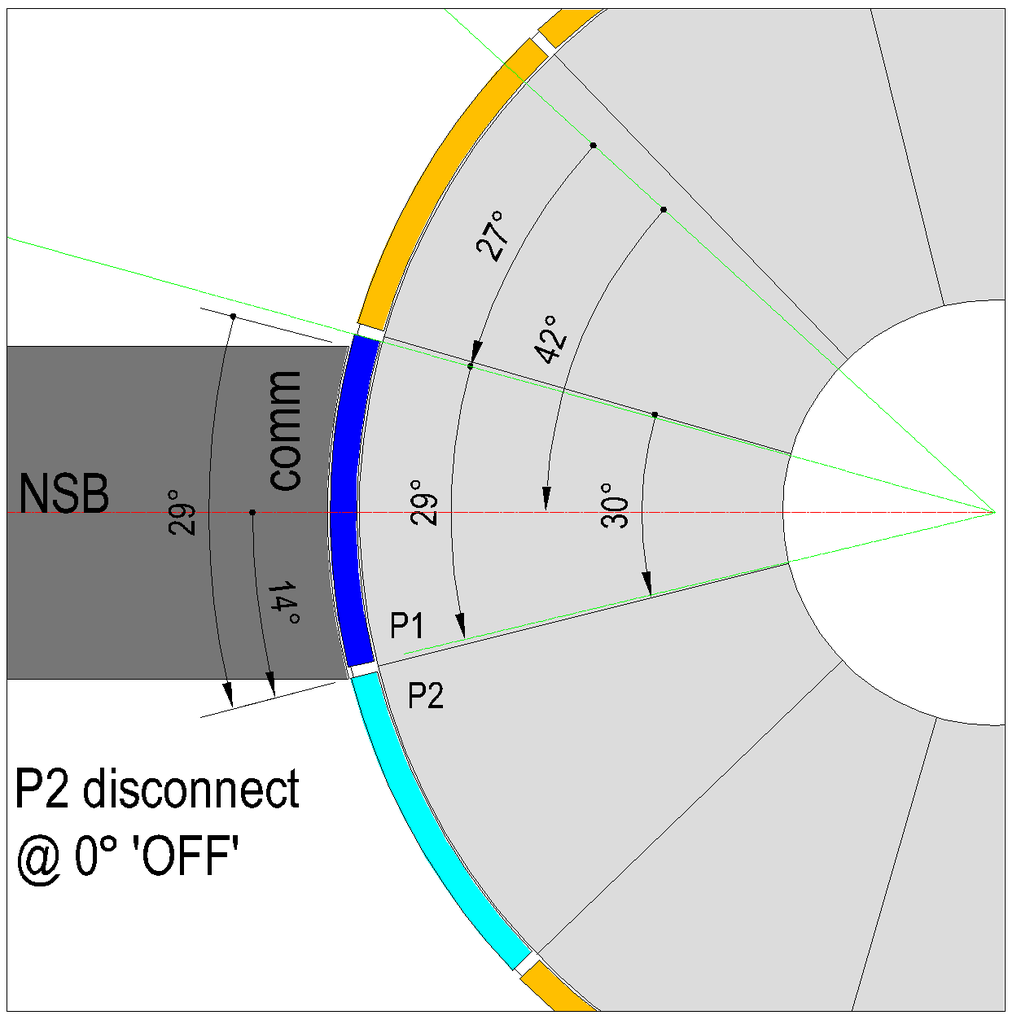

Image 2 - P2 disconnecting.

[IMG] [/IMG]

[/IMG]

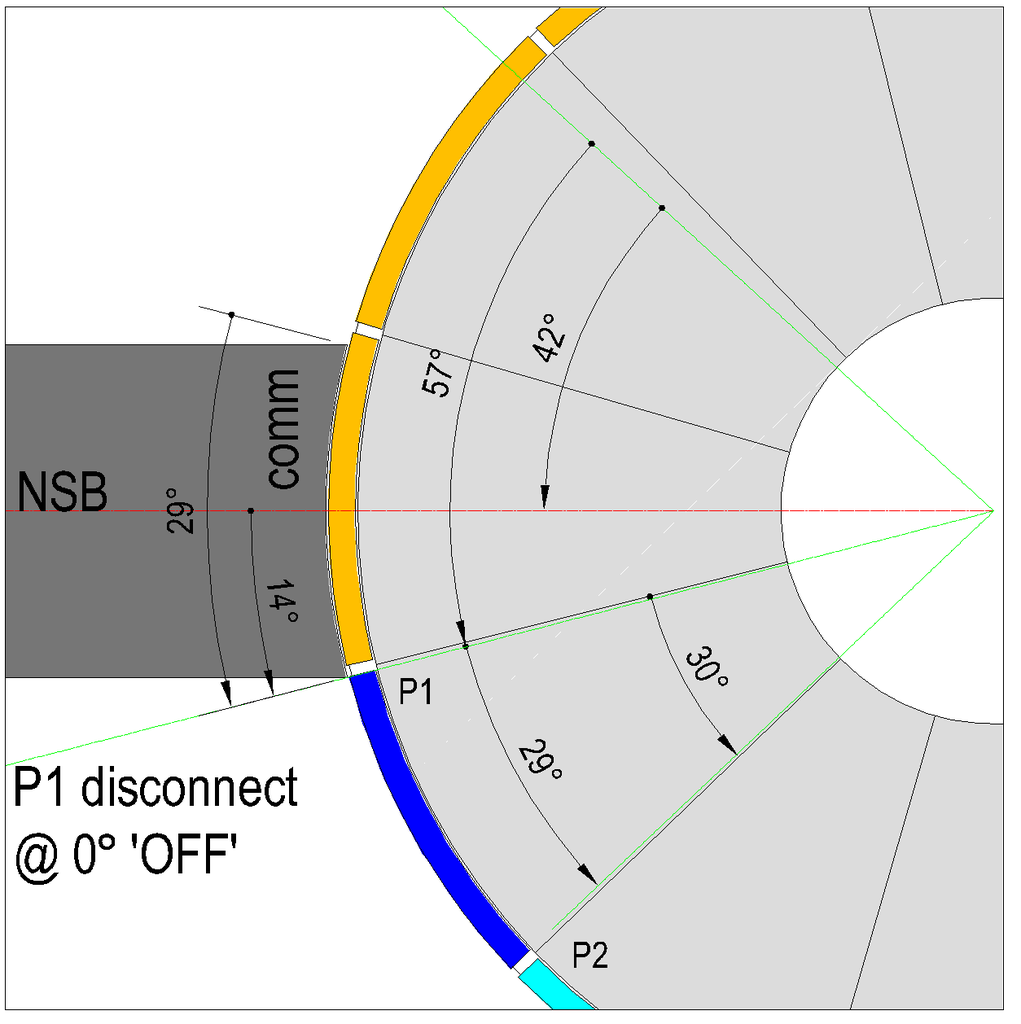

Image 3 - P1 disconnecting.

*This post does not involve single or double commutator motors.

*This post only considers the relationship of the commutator segment(s) and a single brush to establish the critical sweep angle from connection to disconnection.

*These images are for a 12 pole rotor 30░ per pole.

*The angles are whole numbers only.

*The brush is equally divided by the North Stator Bisector.

*The brush is the same width as the comm segment, 29░.

*The images indicate a 1░ angle of separation between the comm segments.

*The 'ON' and 'OFF' angles are assumed to be 'ideal' at 5░ and 20░ respectively.

An explanation of the figures :

Image 1.

P1 leading edge has connected by 1░. P1 trailing edge is 29░ behind the leading edge and is 42░ above the NSB.

Image 2.

P2 trailing edge has disconnected by 0░. The image has advanced by 27░ from Image 1.

Image 3.

P1 trailing edge has disconnected by 0░. The image has advanced by 57░ from Image 1.

The critical angles :

Depending on the winding of the chosen design, single, pairs or groups the angle between the first and last coil bisector must be added to the sweep angle plus the 'ON' and 'OFF' angles.

Example 1 - P1 analysis. A 4 pole pairs winding on this rotor has 120░ between the Coil 1 and Coil 2 bisectors. P1 Coil 1 bisector is set to be 'ON' at 5░ past the NSB and accordingly P1 Coil 2 bisector is 'ON' at 125░. For P1 to disconnect it must advance 57░placing the 'OFF' angle for P1 Coil 1 bisector at 62░ past the NSB and accordingly P1 Coil 2 bisector is 'OFF' at 182░ past the NSB. This is 22░ past the 'ideal OFF' angle and 2░ past South Stator Bisector (SSB) before disconnection. It is concluded a 4 pole pairs wind is not viable for a 12 pole rotor.

Example 2 - P2 analysis. The same 4 pole pairs winding. P1 Coil 1 bisector is set to be 'ON' at 5░ past the NSB. Accordingly P2 Coil 2 bisector is 'ON' at 155░ past the NSB. For P2 to disconnect it must advance 27░ placing the 'OFF' angle for P2 Coil 2 bisector at 182░ past the NSB. Both methods achieve the same result and the conclusion is inevitably the same.

Example 3 - P1 analysis. A 5 pole single coil winding. The coil bisector 'ON' angle is 5░. The bisector has to sweep 57░ before disconnection giving an 'OFF' angle of 62░. Adding an 'ideal OFF' angle of 20░, 82░, leaving 98░ for timing adjustments.

Happy Hunting

mark

Leave a comment:

-

Hey Sam,Originally posted by sampojo View Post

Ufo has remarked on the uniqueness of this design. Another way of saying they dont usually combine 10 poles with quad stators, and maybe for good reason, after all it is a product of my imagination Seems to run pretty nice though, if I don't say so myself!

Seems to run pretty nice though, if I don't say so myself!

Yes, it is 'unique' indeed!...

Typically a Four Stator Rotor configuration must be able to be divided by four in equal number of poles...in your case we have two point five (2.5) poles...and that is not good when it comes to dividing by four interactions your full 360║ Quadrant.

That is why I recommended the single coils overlapped to reduce your coil to coil, bisector to bisector angle.

Sam, if you used the same ten elements commutators that were originally attached to your ten pole rotor...then each segment/element must be around 36║, as well as each pole angle, except they are located at different distances from shaft and that increases the whole circumference. Anyways we have a 1:1 ratio if it would be the case here.If a brush here would be 36║ wide, it would be twice as wide as a comm segment. I don't know a whole lot about electric motor design in general, but I cannot conceive of any benefit to a brush design like that. OOPs. I guess that design might be used often in the symmetric world? Well another strike against that!

If it helps to find out if this design has any inherent good qualities, my brushes are about 3/4's the width of the comm segments.

Now, if you say each brush is about 3/4 of total comm segment, which is around 36║...then brushes are around 27║ of contacting area.This fact, my friend, sets you in some disadvantage than having a brush that is about the same size of segment...why?...just because you will have longer ON Times than normally it takes place (only 9║ difference which is almost nada)...However, also because of this 'scenario' you will have faster/shorter transition time between two segments, which is good. So, up to now we have a 50/50 advantage/disadvantage percentage.

What you really would have to make sure...(and this is the most important part) is about deciding between four pole or three poles coils...I suggested the four poles because it will deliver a much faster motor than the three pole coils...and the only way to find out if the four will work...is to wind two adjacent coils (C1-C2) and "mechanically" hand check if disconnection takes place from C2 before it reaches South Stator Bisector....that's all!...if it don't...then go for the three pole coils...simple enough?

Another thing that I suggest is to try position of your whole switch, meaning the contacting segments from commutator, the wires to connect to them and Brush... WITHIN the Angle between your C1 Bisector to C2 Bisector. This way you would be doing each 'switching' within each interaction magnetic angle...so no adding, no subtracting absolutely nothing from switching sweeping angle...because both angles (magnetic interaction plus switch sweep angle) would be contained within each others. In very simple description...use the CENTER Commutator segment for each Coil total number of poles (3 or 4)...as long as you could bring brush as well there, in order to establish contact related to stator bisectors.

I don't blame you to be confused and still not finding out the point of all this arguments up to now...about your unique creation...I haven't had time to digest your discussions here and previously, but in the end, is it an analysis on whether there is a potential for the "sweet spot"?

Thank you for all these analyses, as I plan my next moves...

First Midaz invaded this Thread with all his BS...

Then join the arguments Mr. Hunting Ross...

Plus all my other added comments related to the flames ...more CAD's and so much screaming...

Sorry about all this explosion about your ten pole...

I bet you never thought it would be that "famous"!!...

Hey, Sam, thanks!...yeap, it wouldn't happen (losing heart here) just because I have such a powerful card under my sleeve, my friend...that it makes me so sure about everything I am sharing here...PS: Ufo, my personal thanks for not losing heart in the tough situations we can find ourselves in dealing in public and finding the perseverance and dedication to share your engineering discoveries and to continue to help us...

Anyways...let me know if now you've got everything above clearer or not...please do not hesitate to say it out loud!

Your ten pole four stator is now the "Prima Dona" of the show...

Kind regards

UfopoliticsLast edited by Ufopolitics; 05-16-2015, 03:15 PM.

Leave a comment:

-

Re: Post 7729 quad 10 pole analysis

If a brush here would be 36║ wide, it would be twice as wide as a comm segment. I don't know a whole lot about electric motor design in general, but I cannot conceive of any benefit to a brush design like that. OOPs. I guess that design might be used often in the symmetric world? Well another strike against that!Originally posted by HuntingRoss p7729 View Post---S---

--S---

@UFO

It is my understanding that we have agreed on all the critical angles making up the connect/disconnect sequence including the 'final agreement' which was including the brush width in the calculation...the sweep angle...the roll off angle or what ever we want to call it.

We are both at a disadvantage, it seems, by not having the complete motor specs. But in fact the only critical spec missing from this 10 pole arrangement is the brush width which is very important. A 36║ comm segment will sweep over an 18║ brush from 1║ ON to 0║ OFF in 53║. A 36║ comm segment will sweep over a 36║ brush from 1║ ON to 0║ OFF in 71║.

If the sweep angle is 53║ then there is 37║ for connect and disconnect. Firing at 27║ or 20║ leaves a 10║ or 17║ disconnect.

If the sweep angle is 71║ then there is 19║ for connect and disconnect. I think we can see there is an issue with this structure.

The position of the brush is unimportant. The size of the brush can be critical.

For your second image, C2 has just disconnected at 21║ from the SSB, C1 is therefore 36║ + 21║ = 57║ back from the SSB. The brush appears to be 18║ wide. To obtain the connection angle we need to back up the coil by 18║. This places the C1 bisector 36║ + 18║ + 21║ = 75║ back from the SSB, 15║ forward of the NSB.

The timing margin appears to be 10║ assuming a minimum 5║ firing angle.

If it transpires that the brush is not 18║ but 36║ then we lose the margin and find ourselves in a deficit of 3║.

Ufo has remarked on the uniqueness of this design. Another way of saying they dont usually combine 10 poles with quad stators, and maybe for good reason, after all it is a product of my imaginationIf Sam can confirm the brush width then we will know for certain what is achievable with this motor.

Happy Hunting

mark Seems to run pretty nice though, if I don't say so myself!

Seems to run pretty nice though, if I don't say so myself!

If it helps to find out if this design has any inherent good qualities, my brushes are about 3/4's the width of the comm segments.

I haven't had time to digest your discussions here and previously, but in the end, is it an analysis on whether there is a potential for the "sweet spot"?

Thank you for all these analyses, as I plan my next moves...

PS: Ufo, my personal thanks for not losing heart in the tough situations we can find ourselves in dealing in public and finding the perseverance and dedication to share your engineering discoveries and to continue to help us...Last edited by sampojo; 05-16-2015, 04:57 AM.

Leave a comment:

-

Hi UFOOriginally posted by Ufopolitics View PostYou really need desperately to seek for psychiatric help Richard...I believe working with your only motor for too long and for the first time in your life , all this windings and loose wires, commutators, brushes angles...etc,etc has been more than what you could handle...it has caused serious delusional symptoms you are exposing all over this Forum.

A delusion is a belief held with strong conviction despite superior evidence to the contrary. As a pathology, it is distinct from a belief based on false or incomplete information, confabulation, dogma, illusion, or other effects of perception.

I am pretty sure there should be some excellent Doctors in Psychiatry in Japan...I am being seriously as a heart attack!

Ask them to run on you an APT "Asymmetric Pathology Testing"

It is good to see you back working on your new motor. Thank you for all of

your efforts getting you ideas out into the public domain. A small note

on the trolls, these people want a free lunch, don't let them take yours

It's show time for you and personally I am looking forward to better things.

There are thousands of us and we all see how these trolls worm their

way in twisting everything around. Take no prisoners, don't pet the trolls

You are the best there is, thanks to all of the other guys too, I won't

name them ALL, you know who you are, standing with UFO.

We are with you UFO.

Mikey

Leave a comment:

Leave a comment: