Originally posted by sampojo

View Post

Sam,

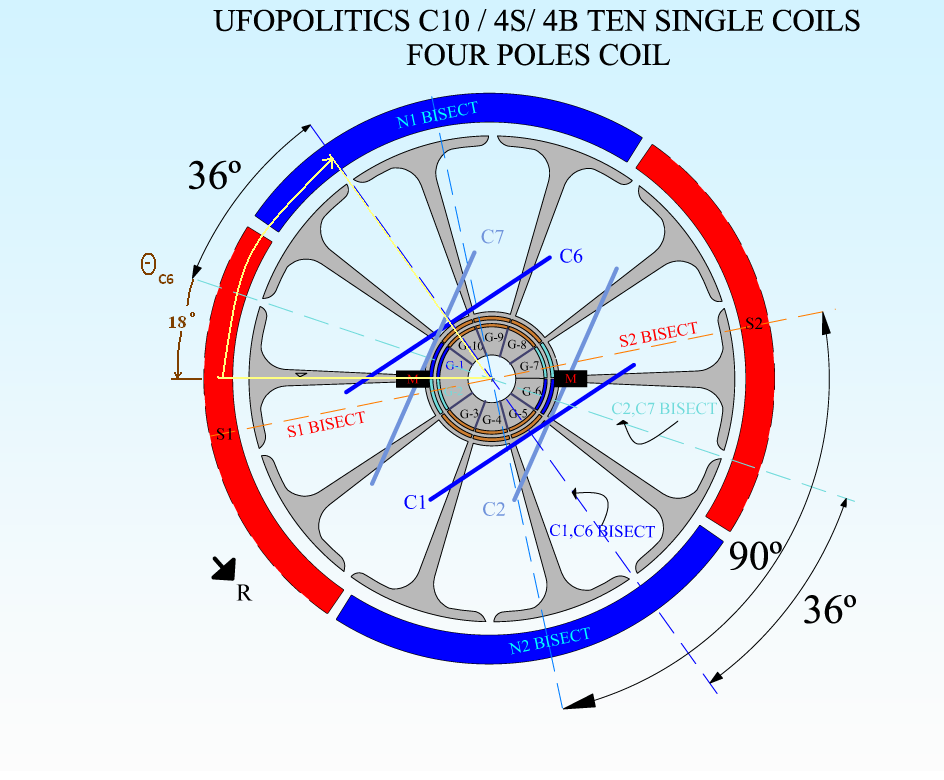

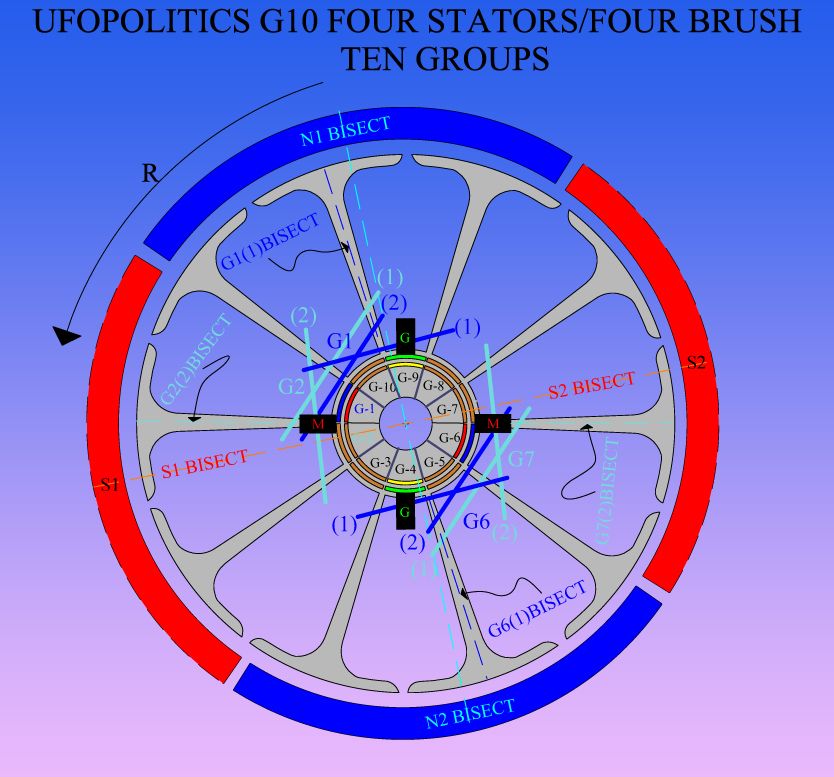

The ONLY reason why I did this design based on Single Coils was because of your set up, which -as I explained before- is Unique.

There are No Ten Pole Rotor spinning within a Four Stator Housing. Normally it should have been a Twenty Pole, then a Pair Wind or Group Wind would be the perfect set up.

Now, as you notice there is absolutely no time, not enough sweeping angle for Generation stage to develop properly.

Besides that, I highly recommend to use as much wire as you could there, and as finer as you could get as preferably Multi-Filar strands.

Otherwise it would be another "Heater Element" as Mark (Hunting Ross) built based on the a1 mogEn.

About the reversing C1 to C6 you are right, I just did not change the original commutator elements labeling from the old group diagram. But you know , and realized...all this hooking wires to elements is completely relative as I also mentioned before. Just have to look for the best convenient end related to brush positioning.

Regards friend

Ufopolitics

Leave a comment: