Originally posted by Ufopolitics

View Post

copied from: 6.3 - Magnetic Force and Field

I don't understand your reasoning. Two magnetic South poles repel and so do two negatively charged particles (repel).

Even more simple...Two Negative charged end terminals will NOT do absolutely NADA...not even a very dim spark when making contact..

...but they further on 'concluded' without any substantial proof that the FLOW will take place FROM NORTH TO SOUTH...as seen the arrows above following a ONE WAY direction...

...but they further on 'concluded' without any substantial proof that the FLOW will take place FROM NORTH TO SOUTH...as seen the arrows above following a ONE WAY direction...

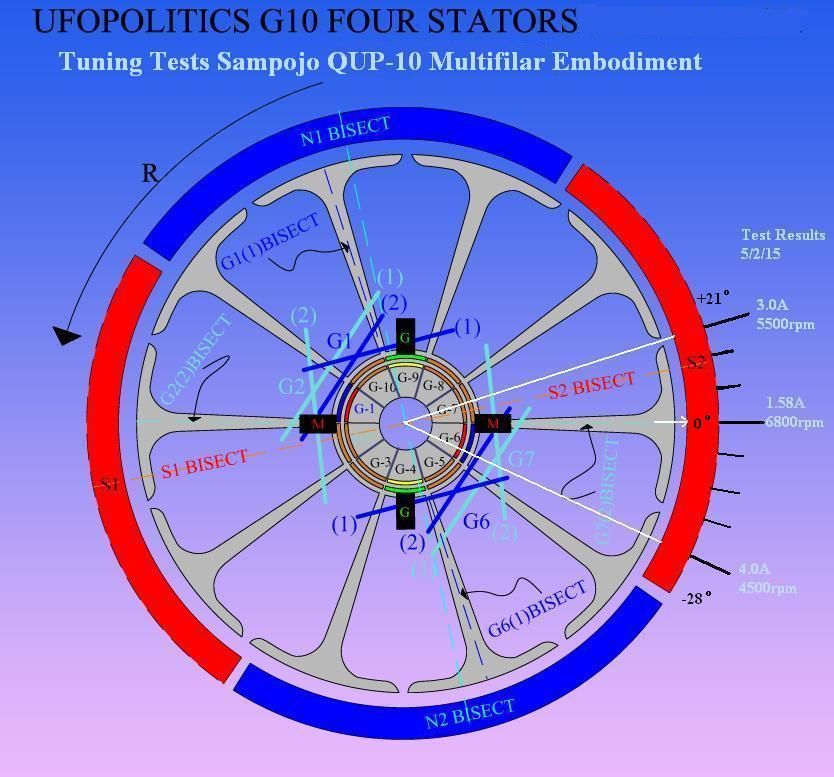

...because you are just adding the 'switcher displacement angle' to the magnetic interactions angle...just because the "switch" is outside the 64.85 degrees from the EM Interactions taking place.(see image below as the one you are referring to):

...because you are just adding the 'switcher displacement angle' to the magnetic interactions angle...just because the "switch" is outside the 64.85 degrees from the EM Interactions taking place.(see image below as the one you are referring to):

)... to start shooting at me...

)... to start shooting at me...

Back at it by the weekend...

Back at it by the weekend...

Leave a comment: