Originally posted by HuntingRoss

View Post

Hello Mark,

Ok, first, great work friend!...you have been -so far- taking the lead here lately with all your builds and testings.

And this Post goes -as well- to All Members working in the development of Asymmetric Machines.

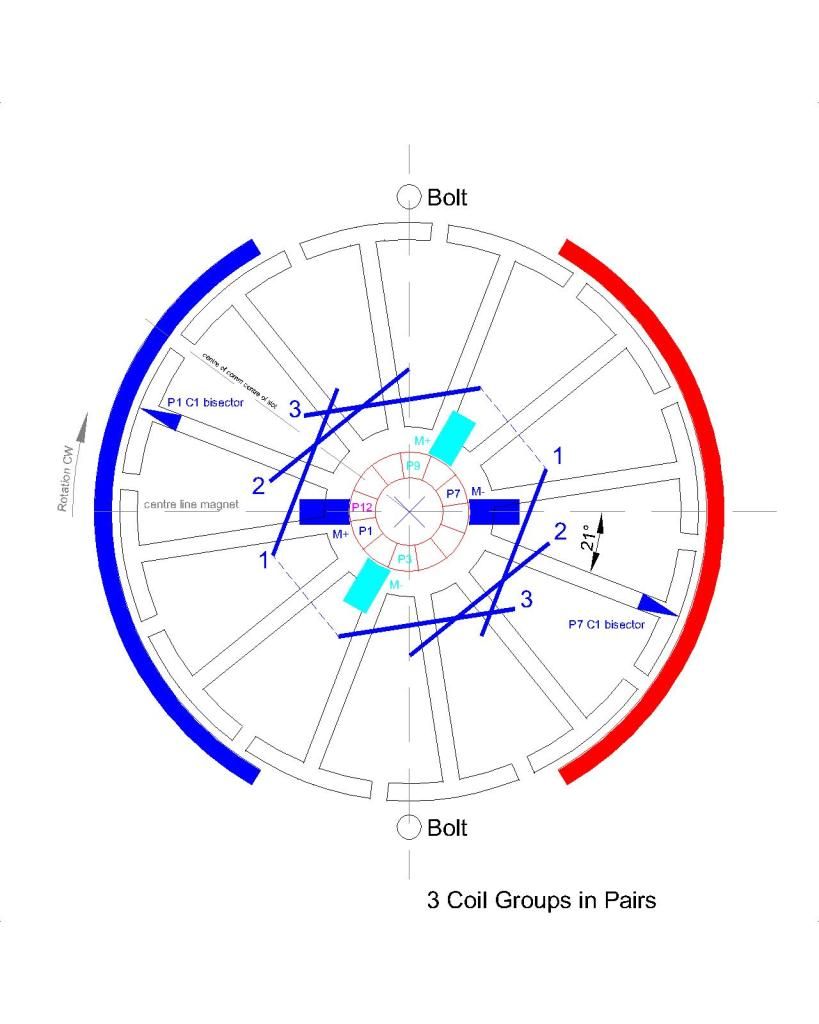

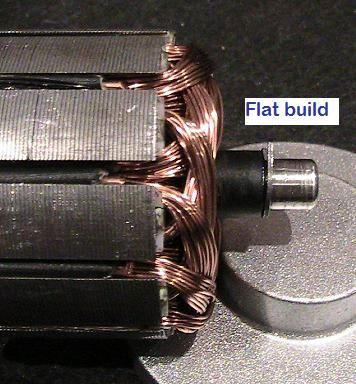

First let's take a look at your Asymm-Symm Hybrid Config:

[IMG]

[/IMG]

[/IMG]And one basic side We ALL must realize is our "working" number of poles when we are sketching our CAD's, and before getting involved into winding...

In your case above we have:

[IMG]

[/IMG]

[/IMG]And We are considering only those center poles, from bisectors on, towards rotation, which are the magnetically strongest poles...disregarding the end poles at coils start-end.

Now, in your Hybrid design, you are also magnetizing the South end poles (in red), which is "similar" (quote marks because it is NOT exactly same thing) result as when we feed Input-Output in a typical Asymmetrical Design. However, you are doing it using only two brushes.

The main point here that I want to direct towards is ...HOW COULD I ENHANCE THE PERFORMANCE?

Ok, mainly, We must understand Symmetry...How it works?....before we move forward to build and make testings to compare results.

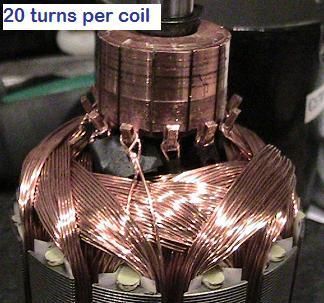

Please, let's take a look first, at Your Symmetric Diagram (OEM) below:

[IMG]

[/IMG]

[/IMG]I have also marked the "working poles" here...and see the GREAT difference versus your design?

First, Symmetry Designs "grab" as much space as it could within Geometry of rotor for each Coil that is wound in a WHOLE SERIES GROUP that comprehends the Total poles at Rotor...and, by the pictures of your original (OEM), I believe I am correct by choosing Five Poles per coil in the total group.

Now, for your Hybrid Design based on only THREE working poles at each end, and Four when two brush elements are contacting...versus SIX at all times, with Symmetrical OEM...Your concept did pretty good friend!

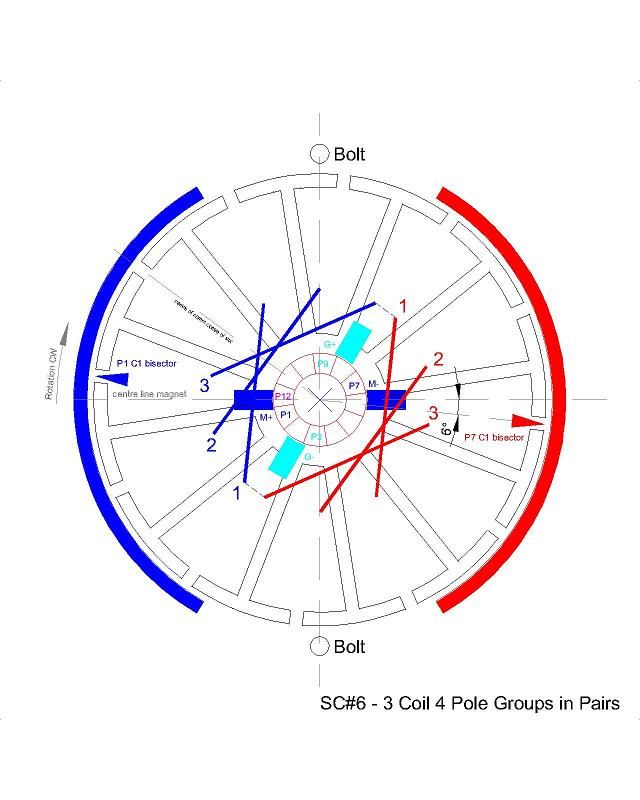

Now, a simple way to Increase your performance, would be to Expand the number of "Working Poles" per Group, starting by each coil...or something like:

[IMG]

[/IMG]

[/IMG]And... all We are doing here is winding Four Pole Coils...BUT, You could even try winding Five Poles per Coil in the Groups...And "our limit" here would be that as long as the ending contact last coil Bisector, would not be binding or too close to South Stator Bisector.

Below Diagram is about expanding our Coils to Five Poles winding :

[IMG]

[/IMG]

[/IMG]Please, forgive me, as I did not move each coil number on above picture...but just the coil lines and "working poles"...

But, take a look now at "working poles" number above, versus OEM in Symmetrical Design...they are about the same, except that when contacting only one comm element there would be five.

In my opinion, this last design would be more 'suitable' to establish a testing comparison with OEM.

The main point on this post, is to learn how to enhance performance by winding coils that comprehend the largest number of poles available, allowed by Geometry, within our coils design.

If you All notice...all I have done is "replace/change" Throw Out Angles by "Number of Working Poles"...

...Maybe this way you all could understand this important issue in our designs much better.

...Maybe this way you all could understand this important issue in our designs much better.Hope this post help you out in your future designs...

Regards

Ufopolitics

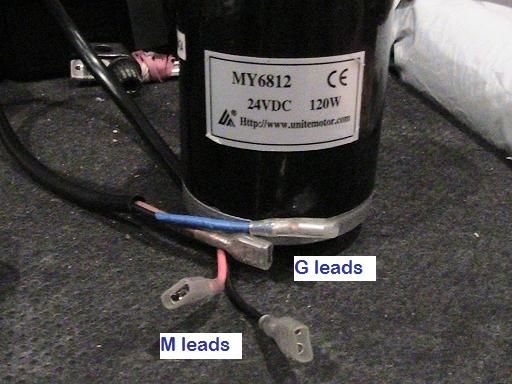

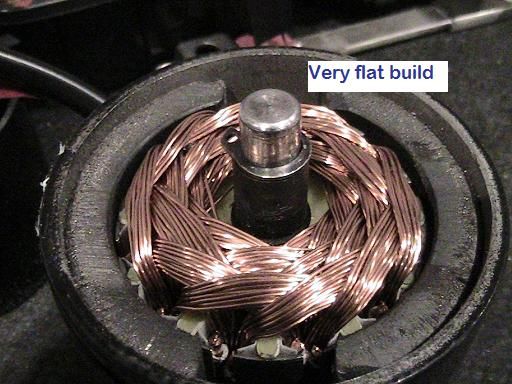

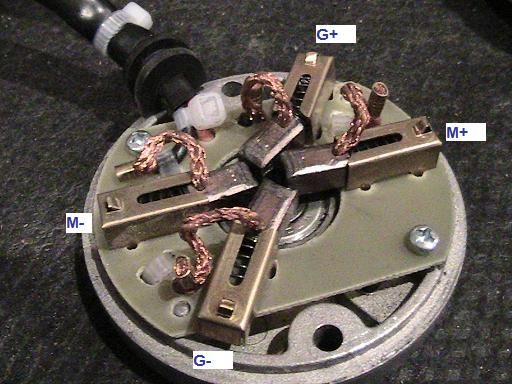

Im posting some pictures can someone tell me if the comutator is damaged beyond use!!!!!

Im posting some pictures can someone tell me if the comutator is damaged beyond use!!!!!

Leave a comment: