Originally posted by Midaztouch

You have been here for two years, reading and going over mostly the Theoretical side...but not replicating from small models I have shown and taught here from the very beginning of this thread, this way you are getting only "half of the picture"...not the practice and experience that Real Builds deliver over time.

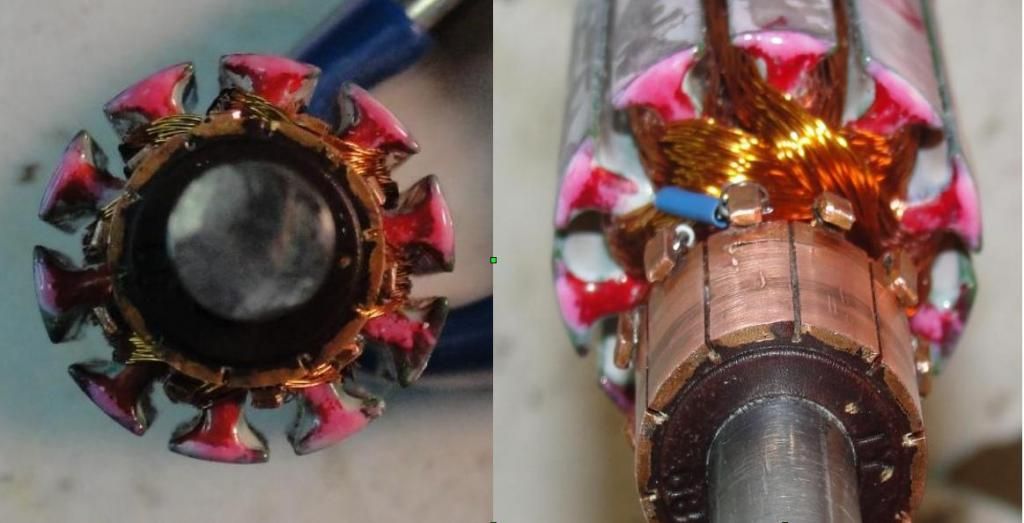

This is a simple DC Motor! I think it's fantastic! I know Asymetric Motors from all of the tests, successes and failures!.... Below are simple facts, that everyone here can except as facts with disputes. It's the difference between an average high schooler jumping -vs- an Olympic gold-medalist jumping.

The only thing I see wrong here is your attitude demonstrated in a couple of last posts.

It was not needed to minimize all the Real work displayed here for two years, in order to make prevail your new idea as the only winner...when you do not even have a $3.99 motor built based on that assumption.

This is not a Coca Cola versus Pepsi Cola marketing competition to reach more sales. This is an Open Source Science and Engineering Thread, not looking to make money out of it.

You starting this thread was and is a Great Honor for Nikola Tesla and HIS work!

Respectfully

Richard

Respectfully

Richard

There is a saying..."Ignorance is daring".

However, I wish you the best of luck in your new thread.

This would be my last post here dedicated to this issue.

Ufopolitics

Leave a comment: