Petrol portable generator

I stripped my aging generator tonight to see what is required to spin the generator once the engine is detached...seems to be not much force is required.

But I find myself in a quandary...the stator is not permanent magnets but windings.

Where does the power come from to energize the stator when there is no battery ? Presumably the stator has to be energized to create the field for the engine to rotate the armature to generate the electricity.

I feel like I'm missing the point. The only slight hint I found in my search is the need to field flash portable generators that have not been used for a long time...implying they have a residual field to make the process start.

If I can work this bit out, my fast spinning motor might spin up a 500w AC generator with a bit of gearing.

Curiously hunting

mark

Announcement

Collapse

No announcement yet.

My Asymmetric Electrodynamic Machines

Collapse

X

-

Single comm - asymm motor

Thanks midaz. The protection for the LiPo sounds critical for the long term health of the battery.

Now...I have seen on here somewhere, an asymmetric wind with one commutator with all the wires being wound onto the shaft at the bottom...but I can't find the posting or the photo that accompanied it.

If anyone can remember where it is I would appreciate a link as I'm curious about the build. Thanks.

I keep forgetting to post this photo. It kept my mind straight whilst winding the motor. If I lost count and had to go back it helped (did that twice) but keeping your focus on which slots to wire became pretty confusing and this made it simple for me.

It's fashioned out of plastic plumbing pipe...in this case 50mm ABS...cut to match the proposed number of slots required.

[IMG] [/IMG]

[/IMG]

Leave a comment:

-

@ Mark

We looked at the lipo-hybrid packs a while back. Children started this trend. They had very low C-rating lipo packs on their RC Cars and wanted to improve performance. It seemed to work very well. Then LS made a pack for his car which needs a high burst of amps to crank the car over. His pack confirmed it was good, for the big builders mind's.

C-rating and farads capacity are very important. You will need some balance for the two, some give and take. Also, please buy a $3 low voltage alarm for the lipo pack.

Keep it Clean and Green

Midaz

Leave a comment:

-

LiFePo4

Hi John

I think Laser's experiment is adventurous for a car for all the reasons you mention plus a whole lot more.

In the context of my scooter or similar low weight vehicle then it could be a game change.

My scooter has two (2) 4.5 Ah batteries in series...so just 4.5 Ah available...the Zippy website has a battery slightly larger than Laser's unit and it weighs in at 8A...that's almost double. Add in the supercaps for their advantages and it would take up the same space in the existing battery compartment.

That looks like equal or slightly less weight and superior power availability...Of course in practice all things might change, but it looks like an interesting avenue to explore.

In truth, my interest lies in a 'sit on' ride rather than a 'stand on'. So I'd like to progress along those lines once I have this experience under my belt.

happy hunting

mark

Leave a comment:

-

Mark, You're exactly right about Laser's battery, the caps should do what you say. I think the unit is a great idea for a dependable system but don't forget the total battery capacity is only about 4 amps if you get in trouble. Lets say you stop for gas and happen to get a tank with some water in it. This happened to me before. The car gets really hard to work with and you need a lot of dependable cranking power to get home safely to get some dry gas. Ain't gonna happen with 4 amps. My opinion only. Also I never saw a car start so easy. The Zippy is a 4200 probably with a 20c rating which means it could deliver about 80 amps and even more for a burst, but I don't know what would happen if the car was hard to start.Originally posted by HuntingRoss View PostThanks John. I think the hybrid battery pack that Laser has devised is an excellent compromise by all accounts. It has the long flat delivery of a battery with the supercaps taking the peak demands and thereby extending battery life...looks like a win-win.

So. Figures today.

Gear ratios first. The motor has a 16 tooth 8mm D bore cog, the rear wheel has an 88 tooth cog...giving a gear ratio of 5.5 : 1.

The wheel is 140mm diameter 440mm circumference (these figures will be rounded). With the back wheel off the floor the OEM motor, on full throttle, spins at 640 rpm...I make that 16.896 km/h...not 20 km/h as stated in the spec which must be an 'under load' spec to be meaningful ! The controller heat sink was a cool 21.9C with braking load.

The 'beast' is now installed ready for 'road' testing later this weekend. The figures for that are, on full throttle...1060 rpm which works out to be 27.984 km/h (no load). The heat sink starting temp was 20.1C rising to 21.3C under braking load.

The OEM motor needs a push start on a flat vinyl floor (kitchen) it is not capable of a standing start. The 'beast' just manages to move me...the main problem being able to stand upright for it to gain momentum.

The slight draw back with my motor build is it is double the length of the OEM motor which means it projects beyond the body of the scooter to the left side...which is my scooting foot and it will constantly get kicked without care...The way the scooter is built, this is not a simple fix but a re-engineering of the chasis.

Updates to follow

mark

And just to add. The bench test for the 'beast' was 6400 rpm...at 5.5 : 1 ratio gives a theoretical 1164 rpm...with an actual 1060 rpm...so not too much lost through transmission.

Good luck, it sounds like you're digging right in there.

JLast edited by DadHav; 10-18-2014, 08:13 PM.

Leave a comment:

-

Figures for today

Thanks John. I think the hybrid battery pack that Laser has devised is an excellent compromise by all accounts. It has the long flat delivery of a battery with the supercaps taking the peak demands and thereby extending battery life...looks like a win-win.

So. Figures today.

Gear ratios first. The motor has a 16 tooth 8mm D bore cog, the rear wheel has an 88 tooth cog...giving a gear ratio of 5.5 : 1.

The wheel is 140mm diameter 440mm circumference (these figures will be rounded). With the back wheel off the floor the OEM motor, on full throttle, spins at 640 rpm...I make that 16.896 km/h...not 20 km/h as stated in the spec which must be an 'under load' spec to be meaningful ! The controller heat sink was a cool 21.9C with braking load.

The 'beast' is now installed ready for 'road' testing later this weekend. The figures for that are, on full throttle...1060 rpm which works out to be 27.984 km/h (no load). The heat sink starting temp was 20.1C rising to 21.3C under braking load.

The OEM motor needs a push start on a flat vinyl floor (kitchen) it is not capable of a standing start. The 'beast' just manages to move me...the main problem being able to stand upright for it to gain momentum.

The slight draw back with my motor build is it is double the length of the OEM motor which means it projects beyond the body of the scooter to the left side...which is my scooting foot and it will constantly get kicked without care...The way the scooter is built, this is not a simple fix but a re-engineering of the chasis.

Updates to follow

mark

And just to add. The bench test for the 'beast' was 6400 rpm...at 5.5 : 1 ratio gives a theoretical 1164 rpm...with an actual 1060 rpm...so not too much lost through transmission.Last edited by HuntingRoss; 10-18-2014, 07:17 PM.

Leave a comment:

-

Hello Mark, I hear a lot about substituting batteries with capacitors but I'm not sure if it's as practical as you would like it to be. I sure would like to be corrected or I mean be informed if this is wrong. I would bet that in the same given space you would never get the performance of a LiFePO4 from capacitors. A battery for $100 is not more than 7 inches long and 1/5 the weight of lead acid and can deliver 10 amps at an almost constant voltage until it's almost depleted. Won't a capacitor slowly and evenly drop it's voltage through the discharge cycle? It might be just me but I really like LiPo and LiFePO4 until something better comes along. I know Laser, maybe I'll ask his opinion if he doesn't imply it on his video.Originally posted by HuntingRoss View PostFinally.

Lasersaber has some good info on this -

Mini BoostPack 12V Capacitor Car Battery Update - YouTube

A small 12v pack which would fit in the existing battery area of the scooter.

mark

Zippy battery link -

Batteries & Accessories>ZIPPY Lipoly

John

Edit: Sorry Mark, I wasn't up to date with his video. I'm not sure about the hybrid. Maybe there's something worth while there. I'll have to look closely at the video.Last edited by DadHav; 10-18-2014, 02:44 PM.

Leave a comment:

-

Thanks Ufopolitics,

Forgive me for asking too much, its because i have not worked so much on winding motors in my past working life and even after going through the threads, i seem to have missed the all North method. However i have gone back to see what i missed behind. Please point me to a particular thread if you remember it.

I have studied Mechanical Engineering with a bit of electrical, Electronics and computer science. Also English is not my first language, so please correct me if i say something the wrong way.

Best regards

Sim.

Leave a comment:

-

Supercaps - Hybrid battery

Finally.

Lasersaber has some good info on this -

Mini BoostPack 12V Capacitor Car Battery Update - YouTube

A small 12v pack which would fit in the existing battery area of the scooter.

mark

Zippy battery link -

Batteries & Accessories>ZIPPY LipolyLast edited by HuntingRoss; 10-17-2014, 06:38 PM.

Leave a comment:

-

Thanks UFO...always safety first.

Thanks UFO. The motor is still stuck together with tape because the longer bolts haven't arrived...grrr...But the plan is to fit the 'beast' to the scooter and do the tests you mentioned previously for heat build up in the controller and battery wires with full 24v potential. Given the OEM draws 0.9A flat out and the 'beast' draws 1.3A flat out I'm inclined to think heat build up will not be an issue.Originally posted by Ufopolitics View Post...on a standing scooter type, a too fast acceleration could have the person driving it to fall backwards, unless is prepared to, balancing herself by tilting her body forward.

Because of the serious amount of torque generated my next plan is to consider fitting it for field testing at 12v only which would appear to be sufficient for the moment and allow everyone to become accustomed to the capability of this motor and it's control. I could either do this by running on one battery or connecting them in parallel and doubling my rated Amp hours to 9Ah.

Despite the OEM motor's lack of torque my daughter has already commented on the backward shove...I hate to think what kind of kick the 'beast' will give.

I've also been trying to source supercaps but the choice is bewildering. Has anyone got advice on the ideal size for this kind of application ?

Best regards

mark

Leave a comment:

-

Yes and No...

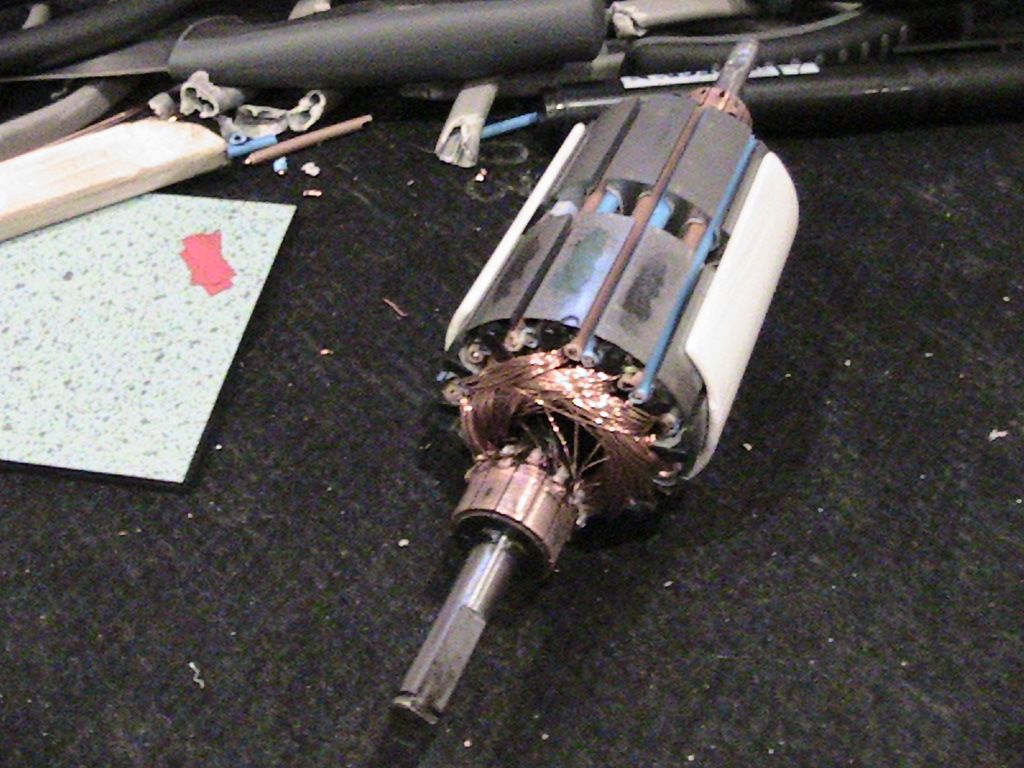

Hello Sim, welcome here,Originally posted by sim View PostCan a twisted rotor like the one in the picture be wound like a straight one?

Unfortunately this is the only motor i can lay my hands. (of course 2). Thanks.

A twisted shaped Rotor like that could be wound with the all North Method.

With the Pairs North South it will work, but will tend to stall/jump, cause the twisted magnetic field projection towards straight stator fields.

One main thing you should keep in mind is to wind it following the 'twisted Spiral" to go "forward" towards your desired direction of rotation, in order to take advantage of the twist and not disadvantages.

Thanks for joining in, I believe that looks like an automotive window motor, typically 10 poles...

Good luck!

Ufopolitics

Leave a comment:

-

twisted rotor

Can a twisted rotor like the one in the picture be wound like a straight one?

Unfortunately this is the only motor i can lay my hands. (of course 2). Thanks.

Leave a comment:

-

I am very glad , Mark.

Originally posted by HuntingRoss View PostTonight I 'got under the bonnet' of the scooter for a look see.

Two sealed lead acid batteries 12v @ 4.5Ah. Total 25.9v on the meter.

First I tested the OEM motor in situ, back wheel off the floor and amp meter connected. A small spike in the amps when the throttle was rolled open and settled to 0.85A.

Stalling this motor is very easy and the stall amps was a massive 8.5A.

Then I pulled out the batteries to connect to my new pride and joy.

With only the amp meter connected the 'beast' took 1.28A @ 5825 rpm.

Removing the amp meter and connecting to volts in and volts out the 'beast' read 23.7v in and 21.3v out @ 6400 rpm within a few revs either side.

Holding on to a piece of spinning metal doing that on the kitchen table was a first for me. And despite the speed it still runs cool.

I think with a prop connected to this motor it would haul something into the air with no trouble...it certainly felt like it was going to lift off.

WHAT a buzz.

happy hunting

mark

Hello Mark,

I am very glad you are having fun with your new 'Beast', that you have build on your own

Now, I would like to insist, in order to take all possible measures of safety here, basically because your daughter would be driving this little scooter, this All NN Asymmetric motors have a very fast response, faster than the old symmetric types, therefore, the controllers designed for symmetry are conceived to "accelerate" according to this slower responses...but, with your new motor the acceleration would be not that smooth...so be careful...on a standing scooter type, a too fast acceleration could have the person driving it to fall backwards, unless is prepared to, balancing herself by tilting her body forward.

Kind Regards

Ufopolitics

Leave a comment:

-

Tonights fun...

Tonight I 'got under the bonnet' of the scooter for a look see.

Two sealed lead acid batteries 12v @ 4.5Ah. Total 25.9v on the meter.

First I tested the OEM motor in situ, back wheel off the floor and amp meter connected. A small spike in the amps when the throttle was rolled open and settled to 0.85A.

Stalling this motor is very easy and the stall amps was a massive 8.5A.

Then I pulled out the batteries to connect to my new pride and joy.

With only the amp meter connected the 'beast' took 1.28A @ 5825 rpm.

Removing the amp meter and connecting to volts in and volts out the 'beast' read 23.7v in and 21.3v out @ 6400 rpm within a few revs either side.

Holding on to a piece of spinning metal doing that on the kitchen table was a first for me. And despite the speed it still runs cool.

I think with a prop connected to this motor it would haul something into the air with no trouble...it certainly felt like it was going to lift off.

WHAT a buzz.

happy hunting

mark

Leave a comment:

-

Embarrassing admission

Apologies one and all for the misleading figures quoted last night...I blame inexperience and poor method.

Connecting the two ends of the motor in parallel does give a jump in revs and torque...BUT...there is no appreciable difference in the amp reading.

The impressive fall in amps was a result of connecting one side through the meter and the other side not.

When I did this with more rigor tonight, the mistake was obvious. Too many leads and exuberance...

However as I work my way up the voltage scale, 12.62v got the motor to 3400 rpm tonight.

mark

Leave a comment:

Leave a comment: