Originally posted by Ufopolitics post 6481

View Post

Announcement

Collapse

No announcement yet.

My Asymmetric Electrodynamic Machines

Collapse

X

-

wiring diagrm reqeust p6481

Ufo I don't understand where the "rear junction" hook up goes and which "two ????? terminals" you are using. I need to see how the G10 does vs the P10 here. where do you hook the bulb up when it looks like you are using gen terminals on the "rear junction".

-

New rotor:GM unipolar dual stator vs QP10 quad stator

Hi Ufo

I am thinking about making a new rotor. I like my QP10 quad motor for power generation capability, since the motor body is wall-to-wall covered with magnets in a quad stator layout. It has a construction weakness in that I used solder on the external wiring connection, that I believe I can replace with crimps. At 26ga it ran a little hot at 130defF coming out along the endplates., .6-.7ohm coil pair wQP10 winding pattern.

I like my doublerotor dual stator alot since it ran cooler, twice the wire then of course and ohms prbly at about 1.1 per group, apparently less powerful too!. I don't like the shorter magnets now either.

You asked me a question back on pg 219 P6566, here is the discussion:

When you asked if I could put the G10 rotor in the body of my QP10 you seemed to imply that the dual stator group winding might work in the Qaud stator design. Maybe not huh? But what about the P10 unipolar which I would like to investigate. Sure I can do the P10 double rotor for a dual stator and we know it should work well, but I like the wall-to-wall magnets in the QP10 motor body. I guess 26ga is still optimum there, since I should be able to recoup heating as a problem by using pulsers, which I am starting a more agressive assembly campaign on those. But I think you have alluded to differences in quad stator designs. And overall I want to test the Pairs unipolar design. I think the 44000 rpms you got on the RS 5-poles unipolar pair design is the effect I want to work with most.Originally posted by sampojo to Ufo P6566 View PostSam: My Quad stator pentagon winding motor did 7500 rpm on one brush set if I remember right, drew 2.5A, 8600 with 2 brushes. I think I had .7 ohms per brush set though, got up to 130 dF the day I blew a brush set, used solder. so it needs reworked.

Ufo: One question...are this two motors (Quad and G-10) same spec's as rotor wise?...If so, could you run the G-10 Rotor inside the Quad Stators/Brushes housing?

Sam: no can do. The dual stator was a double rotor - 4", the quad was 2". I hoped to make up for it being only a dual stator by making it longer, and of course, putting the two bodies together was easier, since you could duplicate the original motor's brush and endplate assembly to the commutator placement, no thinking and simple measurements to dupe.

yes absolutely no adjusting. I think a big drawback now to these motors is the magnet's are shorter in width as I posted earlier on this page. The motors are made to be narrow to fit in a door Bad for doing real work as I have some plans on seeing how much energy it can make. But I am happy with the ohms per group and heating seems very under control and will look at 24v. I think I used 26ga on the quad and it had .6-.7ohms per coil, and the brush assemblies are just not heat tolerant, failed a brush set fast (haven't disassembled yet to find out exactly). Pretty sure its best to pursue your unipolar windings though instead. I would rather rewind it that way, before I do anything serious with it. I might try to repair it just to get good comparisons to the unipolar. I would almost say that I should go up a gauge to 27ga on it also, since it ran so hot. But maybe need to get the pulsers working to see how they help.

Bad for doing real work as I have some plans on seeing how much energy it can make. But I am happy with the ohms per group and heating seems very under control and will look at 24v. I think I used 26ga on the quad and it had .6-.7ohms per coil, and the brush assemblies are just not heat tolerant, failed a brush set fast (haven't disassembled yet to find out exactly). Pretty sure its best to pursue your unipolar windings though instead. I would rather rewind it that way, before I do anything serious with it. I might try to repair it just to get good comparisons to the unipolar. I would almost say that I should go up a gauge to 27ga on it also, since it ran so hot. But maybe need to get the pulsers working to see how they help.

I have enough rotors and commutators to make a new motor core methinks pretty quickly. Many serious home front priorities now however. Yes could there be a possibility that your original RS unipolar pairs is a better design? A new rotor winding of that type would be the ticket to answer that!

Question: Do I need a redesign of the P10 unipolar dual stator design for a Quad Stator motor?

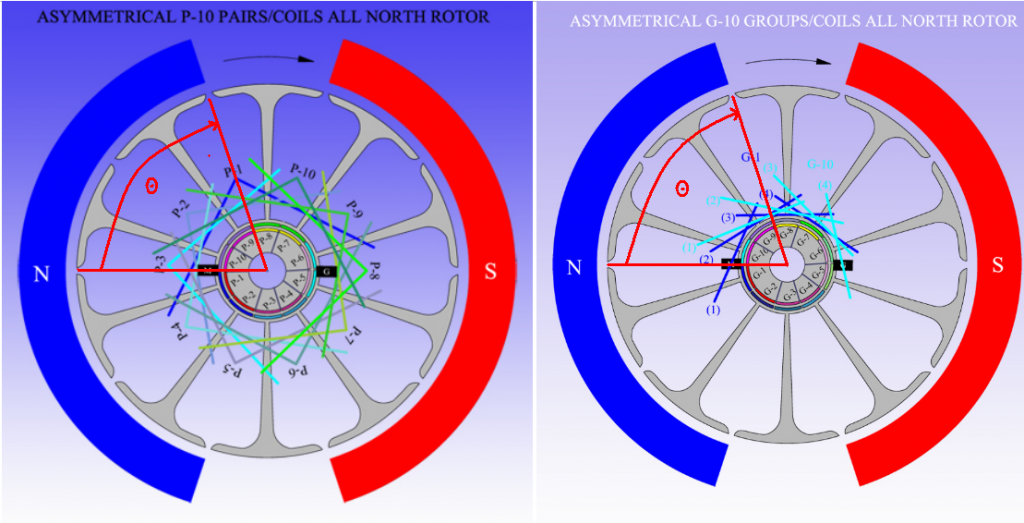

Looks like answer is no if I compare the timing angles, group vs pair unipolar looks constant. But the 20 Pole Quad stator Bosch diagram timing angle looks a little larger at 4 1/2 poles vs. a translated 4 poles (Theta in the diagrams)

10-pole Group vs Pair design have same theta

Looking at coil G1 firing here, 20 pole quad stator has similar Theta, maybe a little smaller by 1 1/2 pole arc?

So It looks like rotors would not be interchangeable in unipolar motors between quad and dual stator designs to me since the theta's are very different, and one leading and one lagging the motor brush.

So a Pair unipolar 10-pole design for a quad stator would use the same timing angle used by the Quad stator 20-Pole apparently, and the sub-coils would subtend 2-poles?

Thanks, UfoLast edited by sampojo; 05-19-2014, 04:14 AM.

Leave a comment:

-

Comment on video and test data on GM window motor

Hi Ufo,

Maybe the motor is breaking in and running easier and more efficiently, maybe even since it is warming up and expanding. That might explain only a temporary creep in rpms up, amps down and creep up on volts, though? But the proof would be if the batteries continue run 2-3-4 times ? longer than a conventional motor even if it performs just somewhere close in the rpm/amp range. So whats the battery behavior on a conventional motor, does it never creep up? A new conventional motor would also have a break-in cycle, wouldn't it? First time I noticed the capacitor in the circuitry, gotta study that to see where you are putting it.

Took some more data on my dual stator. Motor turns better on direction vs. the other, one brush set runs better than the other. Now my motor is 26ga. also, its the group unipolar winding for the 10-pole. I had 11 turns per sub-group coil, 4 subgroups per group at 32' per coil. I calculated this using the Alcatel Magnet Wire guide by wire diameter and resistance, figuring 1.1 ohms per GROUP. The double rotor came in perfectly filled up. I used my best radio shack mulitmeter, seemed to agree with the Alcatel Magnet wire guide completely. How in the world did you get a coil coming in around one ohm on that little motor using 26ga?

mulitmeter, seemed to agree with the Alcatel Magnet wire guide completely. How in the world did you get a coil coming in around one ohm on that little motor using 26ga?

Well anyway, I loosened my brushes up a bit and put some washers to reposition brushes housings getting some more clearances, now getting 3400 rpm on 12v on the best brush set, about 9v on the other brush set measuring output voltage there. When I hooked up a 12v incandescent light to the 9v generator output, it took about .17A and lighted well, and the motor slowed and took an extra .1-.2A.

When the motor was free running on one brush set, it took 1.45A

Hooked up the second brush set as a motor. To do this I had to put the +8v gen. side to the +12v terminal of the battery, got 4000 rpm. I am confused by this, its as if the battery is fighting the "generator" output. Had ammeters on each brush set, and the amperage distributed across both, but not completely evenly, probably due to some extra resistance built into the slow brush set, .6A on it and .85A on the fast one. So how about that, more RPMs at same amps!

Ran it for over a half hour, got up to about 108 on the body, 110 by one brush set, after loading it for a while down to about 2800 rpm and over 2A. So it seems to be able to work...

Hey looks like my window motor runs like your sullivan unipolar pair design, rpm and amp draw very similar.

Getting real intriguing how it might run on a pulser or how a straight Pair coil design might work instead. have to get the wires under control before I can make a nice video. Making another double rotor on the table, Pair design, got the parts.Last edited by sampojo; 05-16-2014, 03:59 AM.

Leave a comment:

-

Now, that's what I'm talking about!I ordered some Supercaps...I wanna do a running test with supercaps on each gate (Input/Output)...and see where we get...

Keep it Clean and Green

Midaz

Leave a comment:

-

Supercaps Testing soon...

Hello Zardox,Originally posted by Zardox View PostYes UFO I did know I wasn't supposed to run it on that much voltage. I just bumped it with what I had in front of me to make sure it was going to spin. I am just experimenting. I have a few of these motors and I plan on having a few different interchangable rotors so I can see for myself the difference. With this gage I don't think I could get another 2 wraps per coil. It may just be a failure attempt but that's ok. It is all part of learning the perameters.

When I finished that little motor with 8 turns...I noticed I still have quite some room to do couple more turns...and as a matter of fact...I did originally on the first Pair...Twelve turns...not saying I did the whole thing though, just P1, but it was too much resistance, then I started taking off pieces/turns by pieces/turns....till I got the desired value.

I ordered some Supercaps...I wanna do a running test with supercaps on each gate (Input/Output)...and see where we get...

Regards

Ufopolitics

Leave a comment:

-

Wonderful Kogs!

Originally posted by iankoglin View PostG'day UFO and Team

I made another attempt at putting the out put back into the battery

the car batteries are ones I am in the process of rejuvenating when I got the batteries they would not hold a charge at the moment I would say they are half way to being completely rejuvenated

The Motor has 2 sets of brushes the Motor brushes are in parallel and the Generator brushes are also in parallel.

You notice that the battery is connected to top of both comms and the output is directly taken from the 2 bottom coms to the Cap bank of 8 12000uf 63v caps in parallel with a Diode on each Negative into and out of the Cap Bank

I have the video on YouTube here

MY 250w 24v output into cap bank back into24 car battery - YouTube

The voltage of the batteries started @ 24.9v rested from charging and finished up24.10v @ 3:00pm and @ 3.25 hours after I finished the video 6:15pm the batteries were rested @25.07v and still after another 1:40 later @7:55 the volts finished @25.12

When I started the video I only had the pot about between 1/2 and 3/4 on

You can notice how the Amps went up when I put the Pot full on at 2:42

then the Amps quickly jumped and settled down

The temperature I am not really satisfied as it went up progressively until it reached 61.9C (144f) I do not know how the batteries will go in Nessie as I was not going to ventilate them But I see now I will have to fan them to keep them cool

I will do a different test after I Re Charge the Batteries and post again

Kindest regards to all

Kogs still at work

Nice Testing Kogs!!

It is better to have the Output Gates in Parallel when trying to charge batteries...since Amps would be higher than in series, where Voltage increases.

Batteries need Higher Amperage rates to be charged faster...but of course, a typical charger would regulate this High Amps discharge process to occur NOT continuously, as it may burst batteries. Same way it is done with large LiPo's Banks charging spec's.

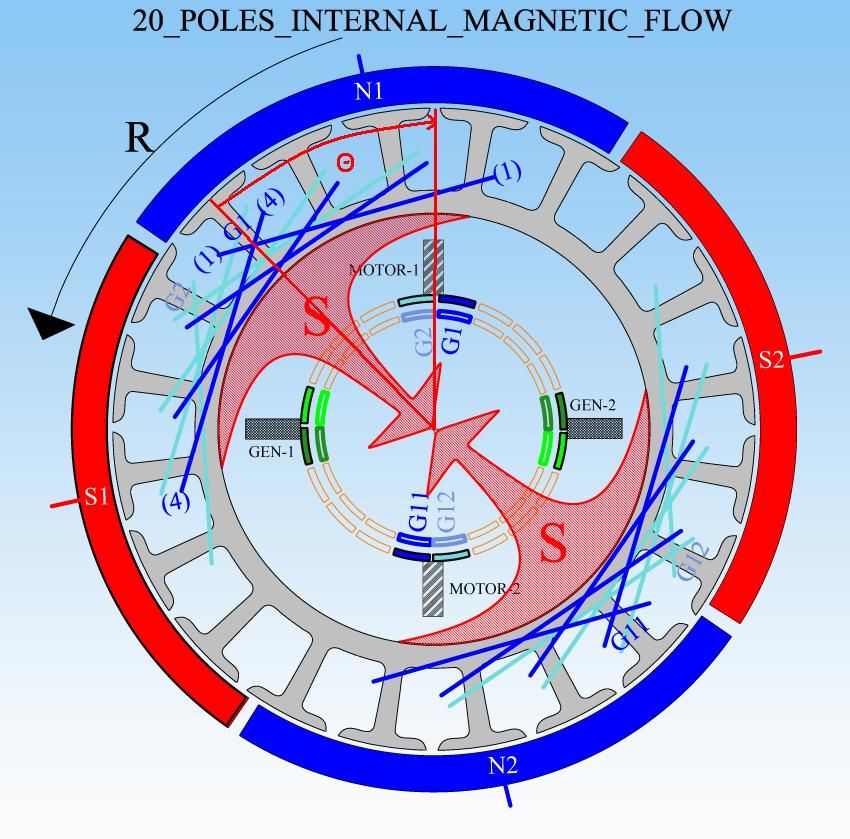

One thing that I will love for you to do...and I know it is hard, cause you already have varnish and balanced those motors...is to go for the ALL NORTH Configuration Kogs...if you could just do another MY1000 Motor like that...preferably a 20 poles...then run the tests and watch the big time difference my friend!

Kind regards

Ufopolitics

Leave a comment:

-

Experimenting

Yes UFO I did know I wasn't supposed to run it on that much voltage. I just bumped it with what I had in front of me to make sure it was going to spin. I am just experimenting. I have a few of these motors and I plan on having a few different interchangable rotors so I can see for myself the difference. With this gage I don't think I could get another 2 wraps per coil. It may just be a failure attempt but that's ok. It is all part of learning the perameters.

Leave a comment:

-

Kogs update

G'day UFO and TeamOriginally posted by Ufopolitics View PostHello Kogs,

Related to adjusting Motor...you should reach the fastest (speed rate) at Lowest Amps draw.

Now, are you using diodes to block batteries being charged preventing them to energize back the gen out?...then verify the diodes are doing their "blocking job" by using LED's Test lamps.

Kogs...32ºC is 90ºF...and that is NOT Hot at all friend!...check the Temp Running spec´s of your original Motor...then compare to those degrees.

In my last video my little Radio Shack Motor was running at 95ºF...and getting up to 100+...that is "warm"..

Regards

Ufopolitics

P.D:Our "normal" room temperature in Florida is 88ºF...

I made another attempt at putting the out put back into the battery

the car batteries are ones I am in the process of rejuvenating when I got the batteries they would not hold a charge at the moment I would say they are half way to being completely rejuvenated

The Motor has 2 sets of brushes the Motor brushes are in parallel and the Generator brushes are also in parallel.

You notice that the battery is connected to top of both comms and the output is directly taken from the 2 bottom coms to the Cap bank of 8 12000uf 63v caps in parallel with a Diode on each Negative into and out of the Cap Bank

I have the video on YouTube here

MY 250w 24v output into cap bank back into24 car battery - YouTube

The voltage of the batteries started @ 24.9v rested from charging and finished up24.10v @ 3:00pm and @ 3.25 hours after I finished the video 6:15pm the batteries were rested @25.07v and still after another 1:40 later @7:55 the volts finished @25.12

When I started the video I only had the pot about between 1/2 and 3/4 on

You can notice how the Amps went up when I put the Pot full on at 2:42

then the Amps quickly jumped and settled down

The temperature I am not really satisfied as it went up progressively until it reached 61.9C (144f) I do not know how the batteries will go in Nessie as I was not going to ventilate them But I see now I will have to fan them to keep them cool

I will do a different test after I Re Charge the Batteries and post again

Kindest regards to all

Kogs still at work

Leave a comment:

-

Ufo,

at no time thought it was changing its configuration. I made a sketch of what I think about your engine (sorry for the bad traits made, but I believe they help to justify my point of view). Seeing how each coil is made, I dont think nro 1 drawing, represent in fact what is your engine. This figure does not show the big difference in your engine, which is the change of direction of the winding, from CW to CCW, which occurs between 0 º and 120 º, and 360 º to 240 º. I think when these coils are energized, these half 120º of the coil, will always leave the asymmetric system, and not the position of input and output of the commutator. The resulting magnetic field across the coil, with its phase inversion, they form a dipole or a toroid with V-faces, and that is what would asymmetrical system. In Figure 2, we see this change in direction of coil winding, with its 02 commutator. In figure 3 shows the generator, that is, when the input coil is "energized" induces a current in the coils to turn, AB coil inducing CD coil. Seeing her figure 5, in connection with the series, I thought that the second switch would run just like a resistor between the AB and CD coils. Thus thought the corresponding circuit would be similar to that of Figure 4. Figure 6 demonstrates that imagined at the end of it. 7 exactly the shape and local input and output commutator. Where my mistake was evident with the creation of a new asymmetry in the output coil, since the entry in a 45 º and 90 º output. Sometimes my engine was not starting, need to move a few degrees to init functioning. Yesterday he went to the balancing, let's see what happens. Does thought wrong? Thank you for listening. I await your considerations and all who are following this brilliant topic.

ps.: once again, sorry for any mistranslation.

Leave a comment:

-

Zardox

Hello Zardox,Originally posted by Zardox View PostOk it was a rainy washout kind of day, so I thought I would work on my 5 pole goldmine motor.

After seeing UFOs latest success with 26 gage wire on his RS motor I thought that I would be experimental and try 22 gage. Every pair showed exactly .03 ohms on my Fluke.

Now my craftsmanship I have to be honest is probably a little bit lacking compared to alot of you other builders but hey were experimenting - right?

Knowing that I needed secure the wires better I wanted to test it to make sure it was going to run before I started slathering it with glue. I just bumped it with 10 volts and it shot to life just long enough for one of my wires to come loose and wedge between the rotor and one of the magnets. It didn't break the wire fortunatley but it did wear the enamel off so I will have to recoat it. I know that it is going to run so I'll go ahead and secure the wires while I'm at it. Not shur when I'll get back to it but more to come. I'll try to get some readings and also try to figure out a way to get some pics posted.

Oh yah I should have mentioned that was 8 turns per coil 16 per pair as UFO suggested.

Please, read my previous post where I uploaded video...I recommend NOT to go above 3.0 to 4.0 Volts with this wind type...

Second, if you have 0.3 is TOO LOW, you need least 0.5 Ohms my friend...and the coils will reduce even more resistance once hot running (at least they did it on mine)

So, pls, check before running it again...and you may need to go 10 turns each coil instead of 8...then measure again.

Regards

Ufopolitics

Leave a comment:

-

First run - kinda

Ok it was a rainy washout kind of day, so I thought I would work on my 5 pole goldmine motor.

After seeing UFOs latest success with 26 gage wire on his RS motor I thought that I would be experimental and try 22 gage. Every pair showed exactly .03 ohms on my Fluke.

Now my craftsmanship I have to be honest is probably a little bit lacking compared to alot of you other builders but hey were experimenting - right?

Knowing that I needed secure the wires better I wanted to test it to make sure it was going to run before I started slathering it with glue. I just bumped it with 10 volts and it shot to life just long enough for one of my wires to come loose and wedge between the rotor and one of the magnets. It didn't break the wire fortunatley but it did wear the enamel off so I will have to recoat it. I know that it is going to run so I'll go ahead and secure the wires while I'm at it. Not shur when I'll get back to it but more to come. I'll try to get some readings and also try to figure out a way to get some pics posted.

Oh yah I should have mentioned that was 8 turns per coil 16 per pair as UFO suggested.

Leave a comment:

-

Portugués:Originally posted by flaviop View Posthello everyone, first of all like to thank everyone who showed their experiences in this forum , and especially to our mentor , Mr. UFO . This is my first post , I have studied this very subject. But like most , I'm just an enthusiast, and I have not knowledge to understand this whole process, besides the difficulty of the language , because I am Brazilian. Seeing the work of our mentor, wanted to try something different . If you need only a motor mechanic to move something , I figured it could remove the generator of the motor winding , and with it , the asymmetry could improve engine performance by facilitating the assembly process , leaving only a commutator. Originally my motor is a DC motor treadmill: 3HP , 90 v , 18 poles and 02 magnets. I made the winding according to the model of 12 poles . Not withstanding temptation , put to work immediately, even without having completed all .... excuse me . Result, in the brush got: 1.3 ohms , 24 V and 16 A. I got a good torque to hold the shaft with two woods . Much force was needed to try to stop the engine . Having limited knowledge on this subject , I would like to hear from you what you can expect from my testing , as well as what I could do to repay all that I learned . The fact is that I was very happy with the result . Thank you again .

Oi Flavio,

Muito obrigado!

Se você não está alterando as configurações originais como o meu motor ... acho que posso ajudá-lo?

Um não elimina o gerador comutador elimina as configurações ... assimétri completa.

Com um único comutador você está invertendo a polaridade (de tensão e magnéticos) enrolamentos independentes em cada volta de 180 º

Eu acho que você está confundindo tecnologia minha assimétrico com Alexander.(mostrado abaixo)

Español:

Hola Flavio,

Muchas gracias!

Si tú estás cambiando la configuración original de mi motor...como crees que puedo ayudarte?

Un solo commutador no elimina el generador...elimina la completa configuración asimétrica.

Con un único commutador estás invirtiendo la polaridad (de voltage y magnética) de los embobinados independientes en cada vuelta de 180º

creo que estás confundiendo mi tecnología Asimétrica con la de Alexander.(mostrada debajo)

English:

Hello Flavio,

If you are changing the complete configuration of my motors...how do you believe I could help You?

Only one(1) commutator does not "remove" the generator from my motors...but the whole asymmetry.

One commutator forces to reverse volts and magnetic fields from each independent coil every 180º

I believe you are confusing my tech with Alexander´s (shown below).

[IMG] [/IMG]

[/IMG]

Saudações

Ufopolitics

Leave a comment:

-

Hello Kogs,Originally posted by iankoglin View PostG'day UFO

While I am waiting for my Reverse switch and 5 pin relays I expect to place the order from China this week and they said I should have them in 5 days

I decided to try the recharging of my batteries by using the Gen output

I am trying this out first with my 20pole 250w motor one of the ones I had varnished and balanced. I had 8 wires coming out one from each brush and using different configurations copying the setup you designed for Nessie.

the first setup was using one power set of brushes and the other 3 sets to charge the motor got HOT. I tried using 2 power sets of brushes and 2 Power sets of brushes the same thing the motor gets hot, I then had the gen sets of brushes in series the motor still gets hot about 32deg. C and climbing.

Please UFO how hot can these motors run Usually they run cool If I don't use the gen input the motors seem to run cooler.

I tried to adjust the position of the brushes to the stator magnets the motor runs slower and draws more amps

I did not really keep any data as I was just fiddling with things to see how to connect everything I am using 8 capacitors 63v and 22000uf each in Parallel the volts to run the motor is 24v

Kindest regards my friend

Kogs Nessie Still a Lady in Waiting

Related to adjusting Motor...you should reach the fastest (speed rate) at Lowest Amps draw.

Now, are you using diodes to block batteries being charged preventing them to energize back the gen out?...then verify the diodes are doing their "blocking job" by using LED's Test lamps.

Kogs...32ºC is 90ºF...and that is NOT Hot at all friend!...check the Temp Running spec´s of your original Motor...then compare to those degrees.

In my last video my little Radio Shack Motor was running at 95ºF...and getting up to 100+...that is "warm"..

Regards

Ufopolitics

P.D:Our "normal" room temperature in Florida is 88ºF...

Leave a comment:

-

Kogs update on Nessie

G'day UFOOriginally posted by iankoglin View PostG'day UFO

I have almost all the electronic parts to complete Nessie's Heart

I am about to assemble this circuit for Nessie and really would like to be able to switch the motor in reverse

What is required to switch the motor and Cap bank could I use a rotary say an 8 Pole double throw and where should I place it I imagine it should be at the Motor before the DPDT 50 amp toggles.

I am in the process of testing the 1000w motor I will make a video both with a copy of the original 6 Mosfet circuit like I have in the lighting of the 5 CFL bulbs and then another one with JS. Monster

when I finish Nessie and you are satisfied with the all North P56 I will wire one I have here,

Kindest Regards My Friend

While I am waiting for my Reverse switch and 5 pin relays I expect to place the order from China this week and they said I should have them in 5 days

I decided to try the recharging of my batteries by using the Gen output

I am trying this out first with my 20pole 250w motor one of the ones I had varnished and balanced. I had 8 wires coming out one from each brush and using different configurations copying the setup you designed for Nessie.

the first setup was using one power set of brushes and the other 3 sets to charge the motor got HOT. I tried using 2 power sets of brushes and 2 Power sets of brushes the same thing the motor gets hot, I then had the gen sets of brushes in series the motor still gets hot about 32deg. C and climbing.

Please UFO how hot can these motors run Usually they run cool If I don't use the gen input the motors seem to run cooler.

I tried to adjust the position of the brushes to the stator magnets the motor runs slower and draws more amps

I did not really keep any data as I was just fiddling with things to see how to connect everything I am using 8 capacitors 63v and 22000uf each in Parallel the volts to run the motor is 24v

Kindest regards my friend

Kogs Nessie Still a Lady in Waiting

Leave a comment:

-

In modern times. there are various kinds of secure devices to provide safe environment for people. For example the security camera can be used to monitor suspicious person come and go in the office or people's own home. Besides the florida vehicle inspection also can be used to set up a security system to ensure our safety in the daily life.

Leave a comment:

Leave a comment: