Originally posted by HuntingRoss

View Post

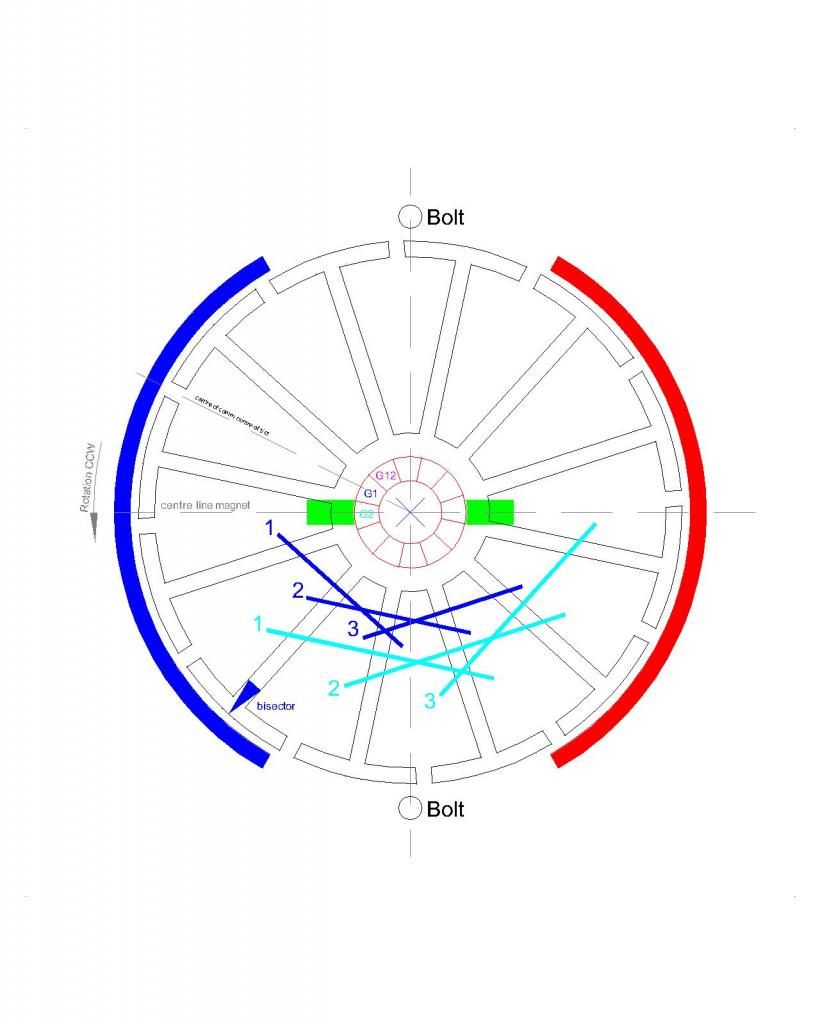

Since your diagram is accurate, could you try your "quick and dirty" test like this? Set your G2 timing back/ccw 2 poles or just move the comm connection forward/cw 2 segments... The amps will be higher but by how much? And is the torque significantly stronger?

Keep it Clean and Green

Midaz

[/URL][/IMG]

[/URL][/IMG] [/URL][/IMG]

[/URL][/IMG] [/URL][/IMG]

[/URL][/IMG] [/URL][/IMG]

[/URL][/IMG]

Comment