Or many English people have been dumbed down so much we don't even speak our own language as good as people not from England!

Update 20th December 2012

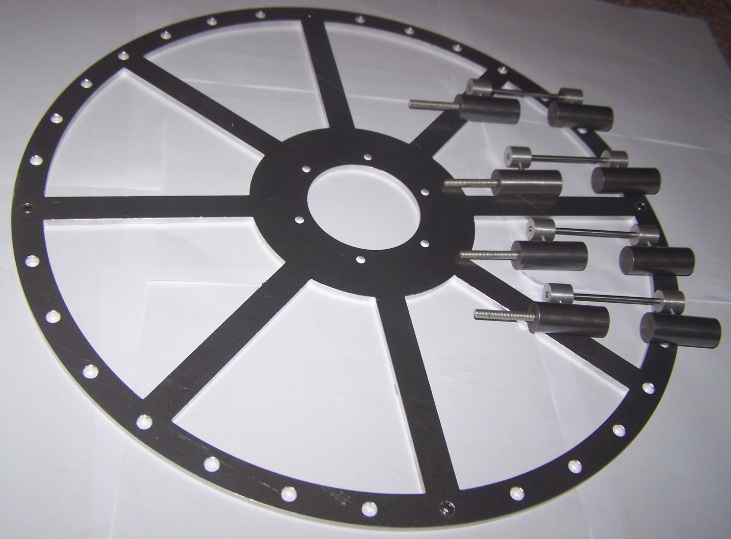

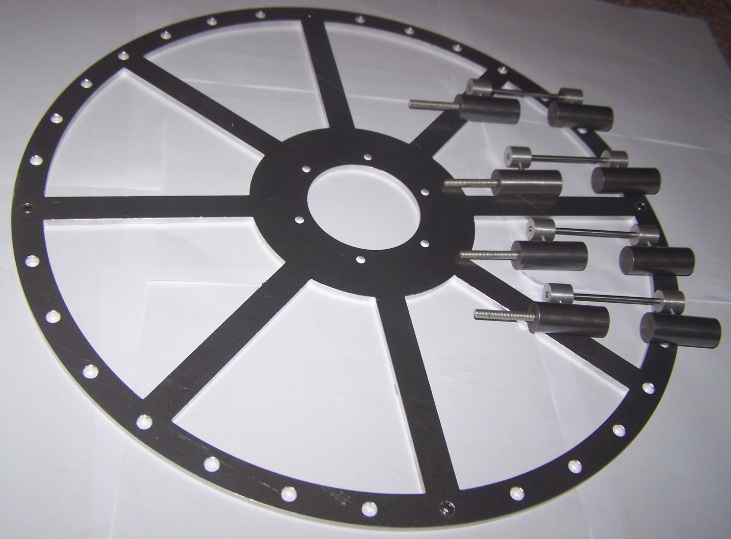

Here are some preview shots of the new parts from the machinist.

These parts should arrive this week all being good.

All the aluminium threaded parts have been made from scratch.

The wheel was laser cut and then machined.

4 bearings are pressed in for now.

The M4 x 6mm stainless steel grub screws were off the shelf.

I have already received most of the stainless steel off the shelf nuts and bolts.

More pics to come.

Cheers,

Paul

Paul

Update 20th December 2012

Here are some preview shots of the new parts from the machinist.

These parts should arrive this week all being good.

All the aluminium threaded parts have been made from scratch.

The wheel was laser cut and then machined.

4 bearings are pressed in for now.

The M4 x 6mm stainless steel grub screws were off the shelf.

I have already received most of the stainless steel off the shelf nuts and bolts.

More pics to come.

Cheers,

Paul

Paul

How would one do this?

How would one do this?

Back at you and to everyone here. Let's hope that 2013 is a break-through year for free energy!

Back at you and to everyone here. Let's hope that 2013 is a break-through year for free energy!

Comment