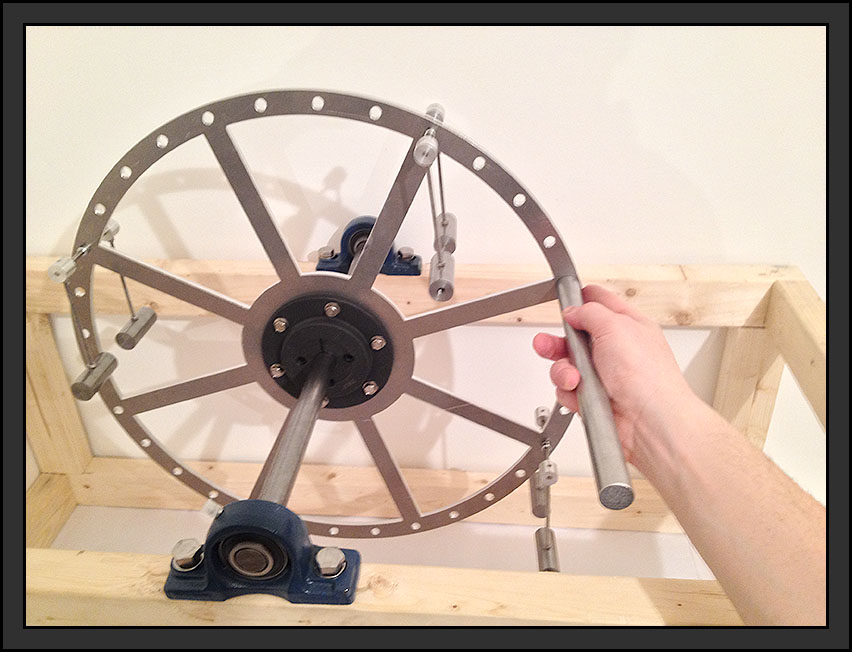

My wheel I'm working on

I built a wheel and am testing some of my own ideas. I put a video up Gravity wheel experiment - YouTube , its more less a project in the works.

I'm not really building exactly what you guys are doing. I'm going to try a ramp, then maybe try some magnet repulsion.

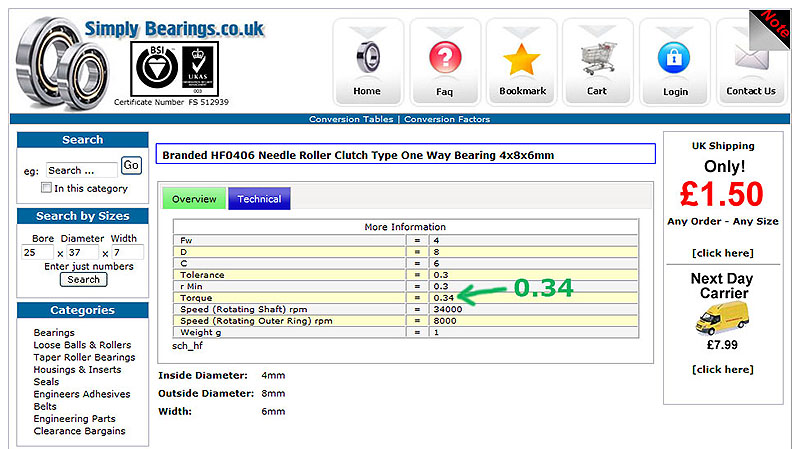

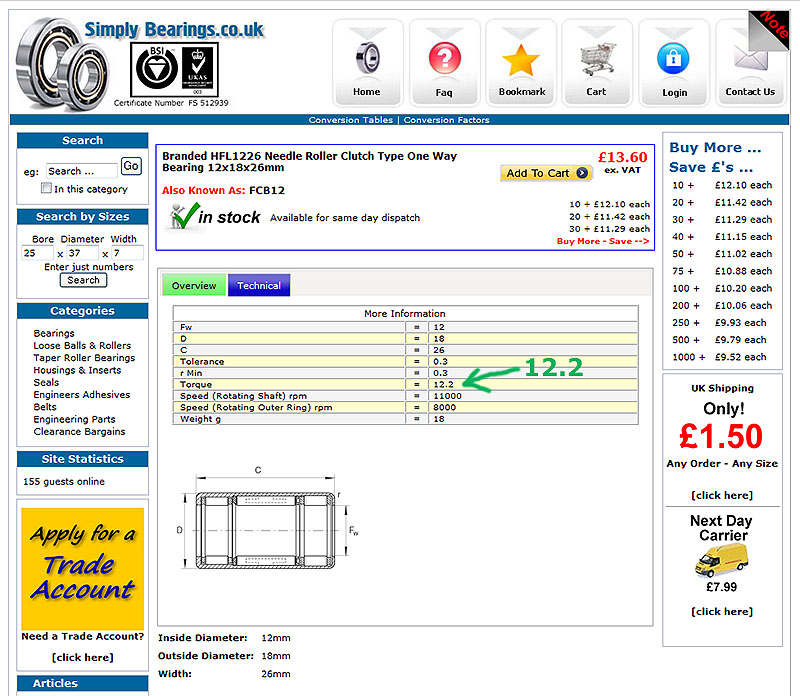

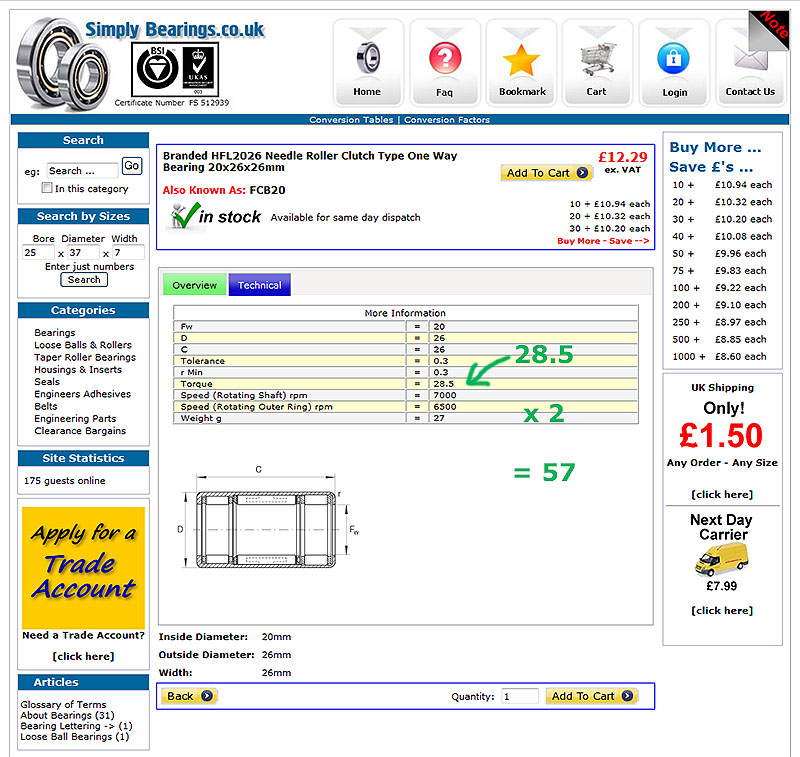

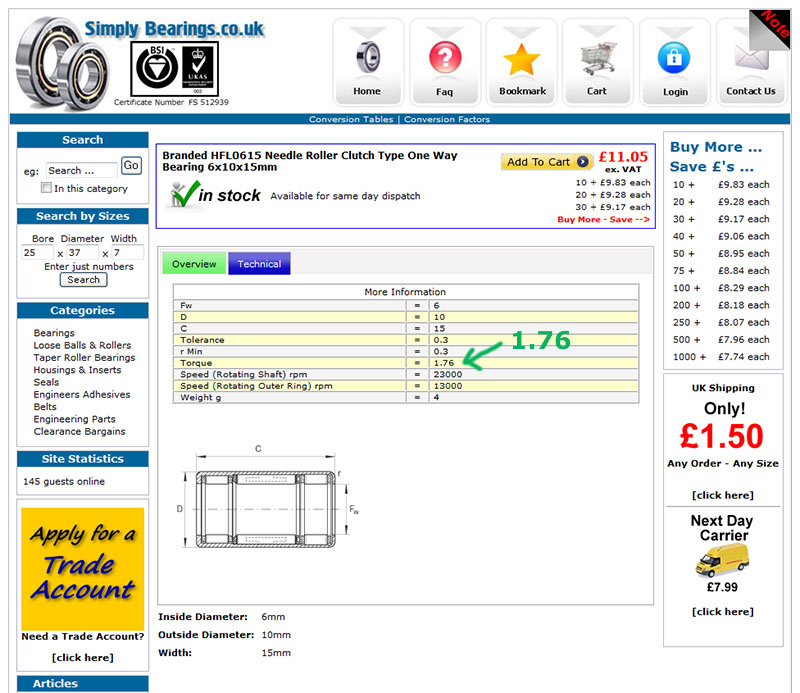

I'm using 6 mm one-way bearings. I used 6mm precision drill rod I purchased from Fastenal. The rod is inexpensive. I drilled a hole in the end of my mounting bolts and pressed the rod into the bolt. I drilled out the center of a nut and pressed the one-way bearings into that. I welded nuts onto the bigger nut to accept threaded rod. It was all real easy to build.

You have to be careful not to rotate your one-way bearing assembly too far as the will jam up into the other ones.

I built a wheel and am testing some of my own ideas. I put a video up Gravity wheel experiment - YouTube , its more less a project in the works.

I'm not really building exactly what you guys are doing. I'm going to try a ramp, then maybe try some magnet repulsion.

I'm using 6 mm one-way bearings. I used 6mm precision drill rod I purchased from Fastenal. The rod is inexpensive. I drilled a hole in the end of my mounting bolts and pressed the rod into the bolt. I drilled out the center of a nut and pressed the one-way bearings into that. I welded nuts onto the bigger nut to accept threaded rod. It was all real easy to build.

You have to be careful not to rotate your one-way bearing assembly too far as the will jam up into the other ones.

.....stop it Paul your embarrassing me!

.....stop it Paul your embarrassing me!

Comment