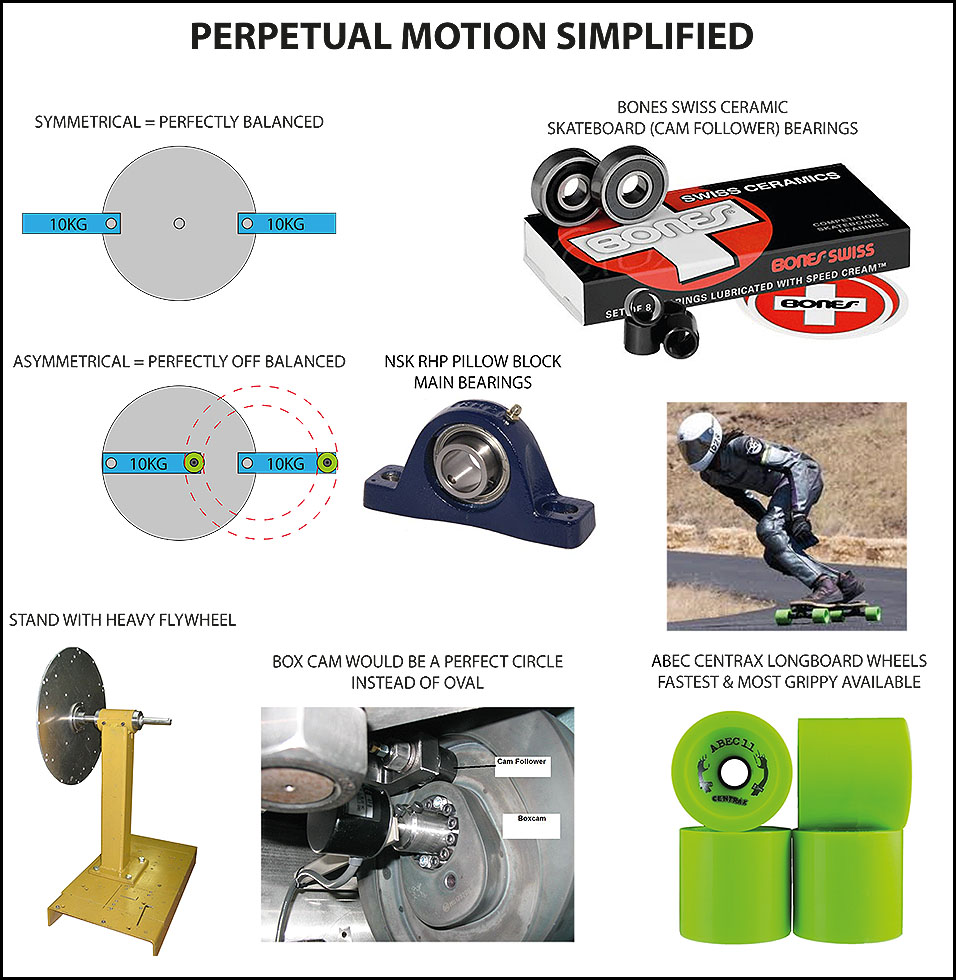

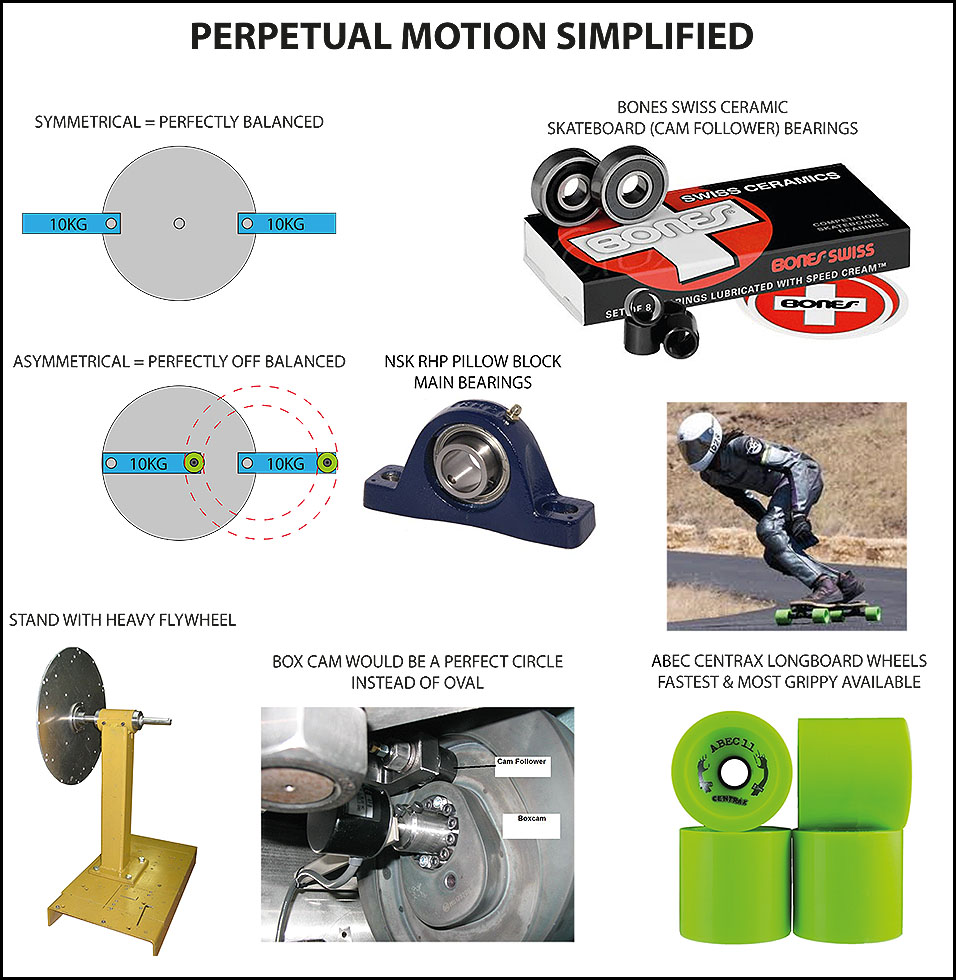

Hi folks, after studying Mikhail's discovery and all the prototypes that have followed by Mikhail, Charlie, Ron, Greg, myself and numerous others for nearly 3 years.

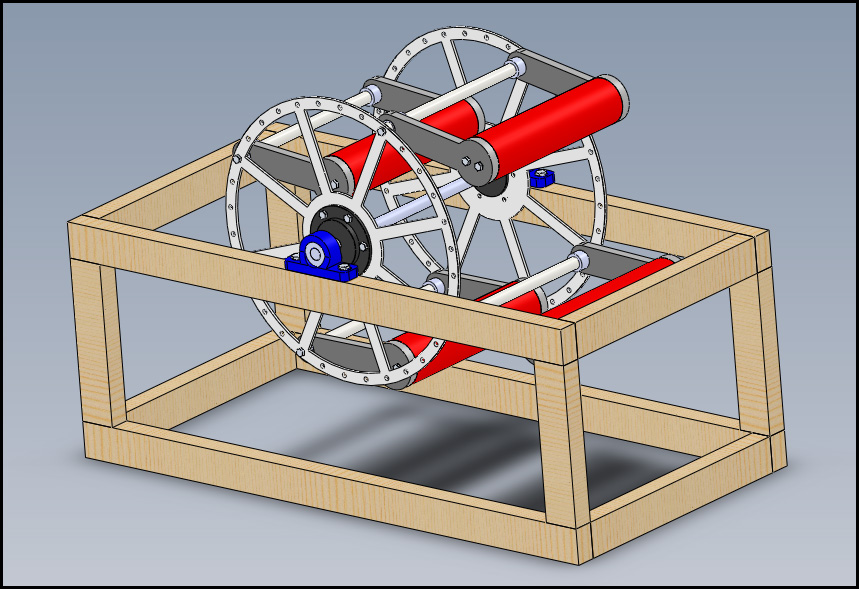

Here is my current design path:

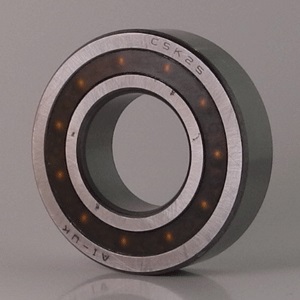

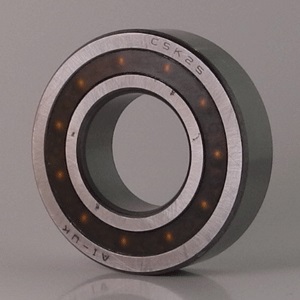

The only thing missing from the picture are the Sprag clutch bearings with "zero backlash".

Stieber CSK20 20mm Sprag Clutch One Way Bearing Without Keyways 20x47x14mm

Stieber CSK20 20mm Sprag Clutch One Way Bearing Without Keyways 20x47x14mm 10-14 Simply Bearings Ltd

"This range of clutches can be used as freewheels and can be used in backstop, overrunning or indexing applications. Freewheel bearings are characterised by their ability to turn in one direction only and thus transmit torque whilst having a zero backlash They are supplied filled with grease and are low maintenance. The torque is transmitted on the inner and outer race by an interference fit into a rigid housing and onto a shaft. The tolerance for the housing fit is N6 and the tolerance for the shaft is n6. Operating temperature range: minus 40 deg F to plus 212 deg F or minus 40 deg C to plus 100 deg C"

I'm building it in the new year if everything goes to plan.

I will post the Solidworks design once it has been advanced a little further.

I've researched the components quite thoroughly and I'm pleased to say they are mostly off the shelf.

In every position the wheel is at maximum off balance.

The frequency could also be doubled by having another wheel and box cam the other side.

As the diameter increases, so can the arm length.

Of course, this could be coupled with UFO's asymmetrical discoveries for an even more interesting outcome.

No radioactivity, cannot be suppressed, easy to understand by the layman.

I think this is the one folks. I don't think it can get any simpler.

Thoughts welcomed please.

Best regards,

Paul

Here is my current design path:

The only thing missing from the picture are the Sprag clutch bearings with "zero backlash".

Stieber CSK20 20mm Sprag Clutch One Way Bearing Without Keyways 20x47x14mm

Stieber CSK20 20mm Sprag Clutch One Way Bearing Without Keyways 20x47x14mm 10-14 Simply Bearings Ltd

"This range of clutches can be used as freewheels and can be used in backstop, overrunning or indexing applications. Freewheel bearings are characterised by their ability to turn in one direction only and thus transmit torque whilst having a zero backlash They are supplied filled with grease and are low maintenance. The torque is transmitted on the inner and outer race by an interference fit into a rigid housing and onto a shaft. The tolerance for the housing fit is N6 and the tolerance for the shaft is n6. Operating temperature range: minus 40 deg F to plus 212 deg F or minus 40 deg C to plus 100 deg C"

I'm building it in the new year if everything goes to plan.

I will post the Solidworks design once it has been advanced a little further.

I've researched the components quite thoroughly and I'm pleased to say they are mostly off the shelf.

In every position the wheel is at maximum off balance.

The frequency could also be doubled by having another wheel and box cam the other side.

As the diameter increases, so can the arm length.

Of course, this could be coupled with UFO's asymmetrical discoveries for an even more interesting outcome.

No radioactivity, cannot be suppressed, easy to understand by the layman.

I think this is the one folks. I don't think it can get any simpler.

Thoughts welcomed please.

Best regards,

Paul

What I see is a nicely balanced wheel. As long you keep pushing it, it keeps turning. When you stop the momentum keeps it turning for awhile, but it eventually slows down and stops. Adding more weights will only make it heaver but not affect its balance. I would expect a true gravity wheel to be self starting.

What I see is a nicely balanced wheel. As long you keep pushing it, it keeps turning. When you stop the momentum keeps it turning for awhile, but it eventually slows down and stops. Adding more weights will only make it heaver but not affect its balance. I would expect a true gravity wheel to be self starting.

Comment