scale matters

The basic Bedini SG using a roller skate wheel and single winding works. It behaves exactly like the scaled up models. However, the output is feeble and it cannot push the battery enough to see the gain. Take the same thing and put 7-8 power windings and a bigger rotor, you get more charge to the battery to see the gain and there is more mechanical work compared to the electrical input.

Virtually every single system we have, electrical or mechanical, that works at over 1.0 COP has a greater gain the bigger it is. We know because measurable results tell us.

For example, if you have a small electrical system and we're dealing with 3 volts and we have a diode on it with a 0.6 volt drop, we have 2.4 volts on the cathode - that is a 20% loss.

But if we have a 30 volt system and put the same diode for a 0.6 volt drop, we have 29.4 volts on the cathode - that is only a 2% loss...huge difference.

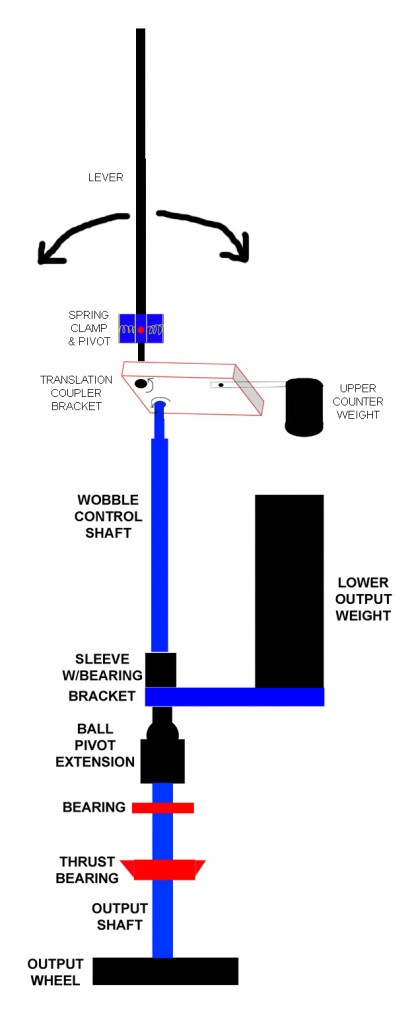

With mechanical systems, it is no different...scale it up and all losses are a smaller %. With the exact same bearings I have with a smaller aluminum weight at the bottom, the mechanical loss is a certain percentage compared to the scale of the mass. If I put a weight 4 times heavier, which the bearings can handle no problem, the mechanical bearing friction is a much smaller percentage compared to the mass of the weight.

Some may use it as an excuse but we know it to be an empirical fact based on the results we can and have measured.

Just because the math remains the same proportionately for any scale, that doesn't have anything to do with how the machines operates on different scales and there is a difference because of some of the reasons I explained above.

Just food for thought.

Originally posted by eltimple

View Post

Virtually every single system we have, electrical or mechanical, that works at over 1.0 COP has a greater gain the bigger it is. We know because measurable results tell us.

For example, if you have a small electrical system and we're dealing with 3 volts and we have a diode on it with a 0.6 volt drop, we have 2.4 volts on the cathode - that is a 20% loss.

But if we have a 30 volt system and put the same diode for a 0.6 volt drop, we have 29.4 volts on the cathode - that is only a 2% loss...huge difference.

With mechanical systems, it is no different...scale it up and all losses are a smaller %. With the exact same bearings I have with a smaller aluminum weight at the bottom, the mechanical loss is a certain percentage compared to the scale of the mass. If I put a weight 4 times heavier, which the bearings can handle no problem, the mechanical bearing friction is a much smaller percentage compared to the mass of the weight.

Some may use it as an excuse but we know it to be an empirical fact based on the results we can and have measured.

Just because the math remains the same proportionately for any scale, that doesn't have anything to do with how the machines operates on different scales and there is a difference because of some of the reasons I explained above.

Just food for thought.

Comment