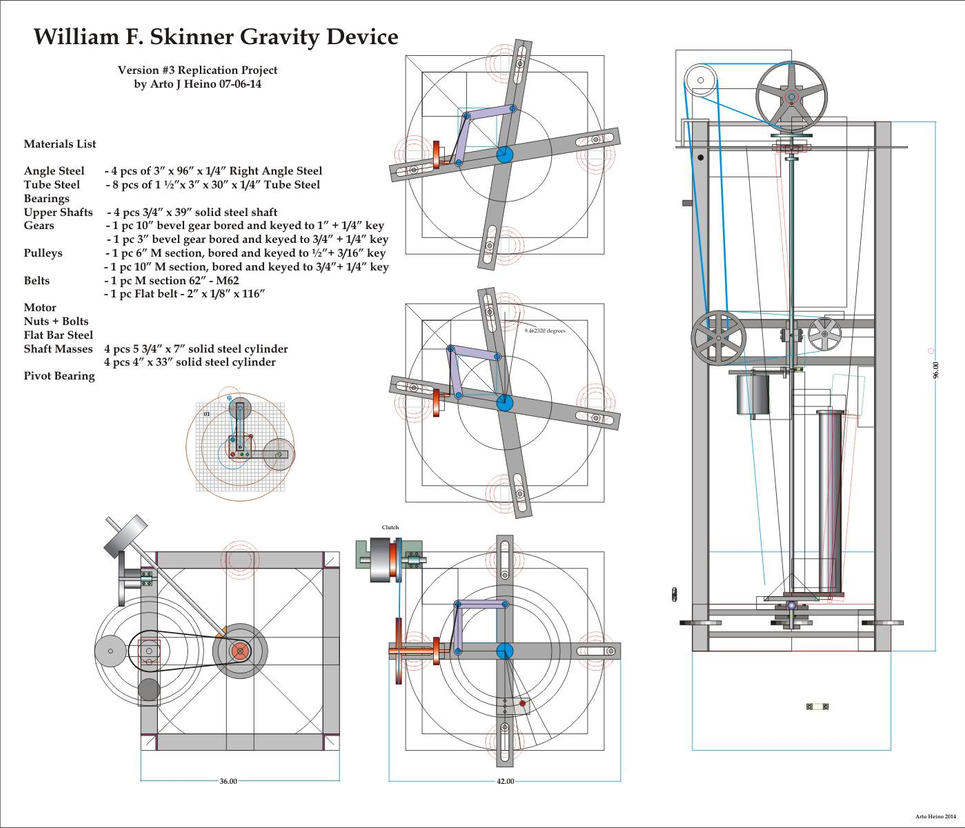

Good job Artoj, could you colorized for understand what object is fixed to another ? I try to enlarge picture for show details but it's not possible

Announcement

Collapse

No announcement yet.

William F. Skinner - 1939 Gravity Power

Collapse

X

-

@Vela Creations

No. I have video of some tests in the 35 watt input range somewhere.Originally posted by velacreations View PostAaron, did you publish test results in any of the videos?

Since you're building a lot of perpetual motion machine mock-ups, you're obviously skilled enough to build this. You should make this your next project and show for the first time a machine that is not claimed to be perpetual motion, but is certainly not hypothetical.Sincerely,

Aaron Murakami

Books & Videos https://emediapress.com

Conference http://energyscienceconference.com

RPX & MWO http://vril.io

Comment

-

Yeah, building it should be no problem. I was hoping to see some results on your mockup to use as a guide for sizing/setup. I have a 20 watt DC motor I'd like to test with this, and I think your prototype might be around the right size for that sort of input.Originally posted by Aaron View PostNo. I have video of some tests in the 35 watt input range somewhere.

Since you're building a lot of perpetual motion machine mock-ups, you're obviously skilled enough to build this. You should make this your next project and show for the first time a machine that is not claimed to be perpetual motion, but is certainly not hypothetical.

Do you remember what the output of the 35 watt setup was?

Comment

-

gravity power

Yes, roughly, but I'm holding any results to myself because I'm not going to post any personal claims. I'm satisfied Skinner's machine is real from all my experiments last year and want to focus on sharing my opinion of how it is built and how it works.Originally posted by velacreations View PostYeah, building it should be no problem. I was hoping to see some results on your mockup to use as a guide for sizing/setup. I have a 20 watt DC motor I'd like to test with this, and I think your prototype might be around the right size for that sort of input.

Do you remember what the output of the 35 watt setup was?

I might change my mind after the conference though. My original intent was to demonstrate the Skinner machine at the conference but was asked so many times to do a presentation on the plasma ignition that I choose to do that instead.

-------------------------------------------------------

@All, I see another discussion about the Skinner machine that are already trying to distract people from the truth. This is referred to as a gravity powered machine and for good reason. Gravity is obviously not the only input as we pay for electricity for the motor that operates the upper input mechanism. But that sets up a situation of imbalance that allows gravitational potential to be converted to real mechanical work so gravity does contribute to work. When gravity pushes on an object and there is resistance to this (the load taken from the machine), then gravity is used as a power source and anyone claiming anything to the contrary are ignorant of the facts and are spreading disinformation.Sincerely,

Aaron Murakami

Books & Videos https://emediapress.com

Conference http://energyscienceconference.com

RPX & MWO http://vril.io

Comment

-

I am principally a model maker with little space or resources to be able to build full size mockups on things i am not sure work. But this looks quite straight forward to make.

I was thinking of a miniature servo motor , or small rotary to linear linkage to do the kicking back and forth and a few universal joints as found in model boat prop shafts....

and a nice big cylindrical lead fishing weightLast edited by eltimple; 06-06-2014, 12:58 AM.

Comment

-

Models

velacreations and eltimple, the sizes I have indicated on my last design, are in inches, and all the proportions are accurate to best estimation +-1/8", it is very hard to engineer something from a copy of a grainy film that is 75 years old. I must thank Aaron again for simplifying the motions involved. Williams design fits perfectly with some of my concepts of a mechanically engineered vortex, something that is at the heart of anomalous behavior of multiple rotating systems. More will be shown as soon as I have the time. Regards Arto.

Comment

-

you got it

That pretty much looks right - just make sure the upper input lever is not right in the center of the translation coupler. Weight, upper and lower rods have to be in that plate in the right relationship to each other.Originally posted by eltimple View Posttrying to work out how to post pic here

until i can draw it i won't understand it...i think i understand itSincerely,

Aaron Murakami

Books & Videos https://emediapress.com

Conference http://energyscienceconference.com

RPX & MWO http://vril.io

Comment

-

Update V#2

Great work eltimple, Aaron is correct the wobble plate is crucial. I have drawn up another design for the top, slowly working through each nut and bolt. The sizes are very close to the real proportions on this drawing, the clutch mechanism will be drawn separately, along with all the other details, Regards Arto.

Comment

-

Optimizing?

Nice video. Clear evidence that thermodynamically open systems--even over unity systems--are both possible and reasonably easy.

This particular machine though seems to cry out for some engineering. Each of the rotating shafts has a resonant (think most efficient) frequency based on its length, mass, mas of the weight, etc. Similarly whatever you want to use to draw power off the working end will have a naturally resonant frequency. For instance we know if we make the main shaft very tall and very slow we get more time for gravity to work its magic. OTOH, a faster rotation gives a larger moment of inertia. We want to find a size and speed that matches whatever we're trying to do. In electronics we call it impedance matching.

The work could be done theoretically (that's what calculus and computers are for) or experimentally. Sure seems like there's some room for building one, trying different weights, different lengths, etc. Maybe even some work on a governor like steam engines and constant speed propeller hubs use.

I mention it 'cause I'm in a tiny apartment and no way to actually do that kind of work myself.

Have fun!

Comment

-

sugestion

For easy scalling up of the weights ,I think an cheap an relativeley easy method would be to take some pvc pipe at desired diameter and to pour concrete inside of it....if we put in the middle of biger pipe a small diameter pipe before pouring the concrete ,after concrete curring we will have a cylinderOriginally posted by Aaron View PostHi Dave,

I was actually going to use solid steel stock of maybe 3 inches in diameter or so - at 2 feet long, it will be pretty dang heavy. That might actually be a bit much for this build but I definitely need it more heavy than the aluminum.

with a hole in midle that can be removed from the midle shaft ( if we want to change the weight with different one)Last edited by sinergicus; 06-07-2014, 08:19 AM.

Comment

-

[QUOTE=artoj;257130]Great work eltimple, Aaron is correct the wobble plate is crucial. I have drawn up another design for the top, slowly working through each nut and bolt. The sizes are very close to the real proportions on this drawing, the clutch mechanism will be drawn separately, along with all the other details, Regards Arto.

Thank you for your drawings...would be a a good thing for skilled guys to make a 3 D clip in motion for better understanding of the design like Ufopolitics has done with his motors...for me is not clear the mechanism in the upper part of device at the conections of levers with with weigts through excentric square plate ( the levers seems to move back and forth but at the base the levers seems to make small circless) and also at the most higher point that in the movie we cannot see..

Also ,how we know the dimension relation between that 2 weights? How to find the optimum dimension between that 2 weights?Last edited by sinergicus; 06-07-2014, 08:04 AM.

Comment

-

Update V#3

As you can see I have re-arranged a few bits, the top part has still needs more work to replicate Williams design, there are many other ways to create the scissor action, the rotating upper shafts are now configured correctly. There is a different crank system at the end of the shafts, which I have not added as yet. I hope this update will inspire those who are working on there own version. Regards Arto.

Comment

-

would you say that the large weight, although appearing vertical , is probably leaning 10 to 15% into the direction of rotation?

also , i am trying to understand why the weight is fixed at its base and not at either end, unless of course fixing the weight at its end forms a mechanical moment or lever of sorts.. off to buy nuts and bolts and a lot of heavy washers since getting the weights right may be a challenge..

looking at the weights again

estimated at

5 and 3/4 x 7 therefore volume is 181 square inches

4 x 33 therefore volume is 414.69 square inches

suggesting that the larger weight may be around 2.5 times the smaller although the weight distribution is probably the black art here and not the values themselves

Comment

-

Thank you Aaron for bringing this forward and creating interest in it.

And thanks to the members who have started studying it.

I have examined the video to a certain degree and find this a very interesting device. As I see it, it creates a continuous falling action for the larger lower weight by changing the center of gravity.

Just a few observations.

I believe that the top rod is in an actual circular motion connected to a rotating arm at the very top where the power is being transmitted into the machine.

Just because the lower hinge point for this rod is moving backward and forward doesn't mean that the rod isn't going in a full circular fashion.

The motion can be seen best at the very top of the machine, at the start of the video.

I also believe the top rod is connected directly and securely to middle connecting plate, as a bolt can be seen on the side of the plate that would likely be used to fasten it.

Anyway just my take on some of the parts, hope it helps.

Comment

Comment