Originally posted by Turion

Yes that is a good way to put it. Measure the energy it takes to rotate

the rotor over and above idling costs, next measure the drag/cost of

bringing the static field of a coil into close proximity of magnets, next see

if shorting the coil returns the rotor to zero drag costs, collect the energy

and return it to the input to get OU?

Then keep adding a coil til high COP is reached.

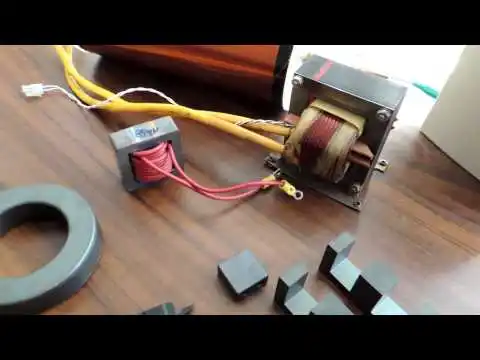

If more reactive core materials harvest more energy then use them.

Iron is fine for 60hz but what about 300hz? Also tinned wire has been

a known way of collecting extra energy with a little bit higher frequency.

Comment