And you are still the best that we have up, but no working example

available. I learned much from you and am thankful. You must remember

now and in the future that I want my 14 year to show everything and I

won't subject him and others to belittling

behavior

behavior

Not everyone is as strong as us and besides is a bad example.

It is time someone shows a working unit that goes with all of the blah

blah blah. People want to see it working first, then you will get some

investors. Jordan is barely a teenager, he don't care about investors.

There are motors all over the web that use internal magnets added

to cancel magnet pole locking. Been around 150 years. Not many will

come right on and show you what they did inside that motor. Same

thing with all free energy on the web, nobody gives. But of course

they want to save the world.

PLZ>>>>>>>>>>>>>>

PLZ>>>>>>>>>>>>>>

Just a line of bull

On the other hand you gave more than most. AAA+++ like I said

you are the best so far.

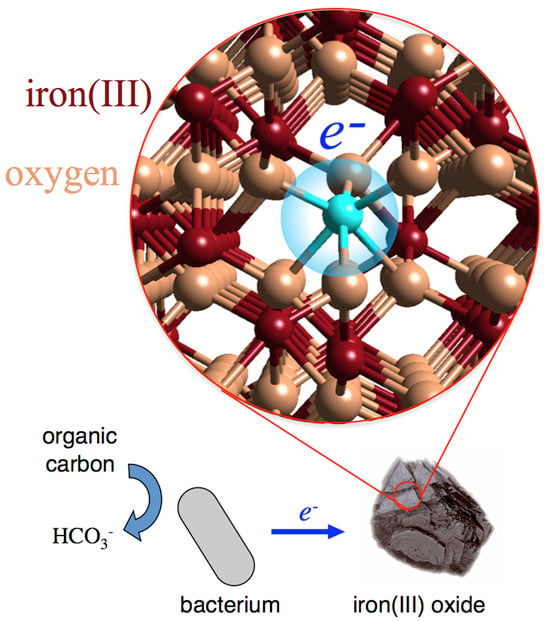

Now on to a working example. I am working on a teaching aid that shows

the possibilities for magnetic alignment of composite iron oxide with

additives. This aid helps to teach the lesser to get them up to speed

before they reach 70 yrs of age. An aluminum mold will press composite

as it is heated. magnets are placed to align the material.

Hypothetical ideas are without meaning unless practical designs are

shared. This is how to do it. It's all pie in the sky.

What and how is quite different than "JUST DO IT" We can not expect

everyone to be a mechanic and scientist, and a Chemist and an inventor

plus a master rigger, these are talents possessed by the collective.

Everyone must share their gift or nothing gets off the ground.

.................................................. .....

available. I learned much from you and am thankful. You must remember

now and in the future that I want my 14 year to show everything and I

won't subject him and others to belittling

behavior

behavior

Not everyone is as strong as us and besides is a bad example.

It is time someone shows a working unit that goes with all of the blah

blah blah. People want to see it working first, then you will get some

investors. Jordan is barely a teenager, he don't care about investors.

There are motors all over the web that use internal magnets added

to cancel magnet pole locking. Been around 150 years. Not many will

come right on and show you what they did inside that motor. Same

thing with all free energy on the web, nobody gives. But of course

they want to save the world.

PLZ>>>>>>>>>>>>>>

PLZ>>>>>>>>>>>>>>Just a line of bull

On the other hand you gave more than most. AAA+++ like I said

you are the best so far.

Now on to a working example. I am working on a teaching aid that shows

the possibilities for magnetic alignment of composite iron oxide with

additives. This aid helps to teach the lesser to get them up to speed

before they reach 70 yrs of age. An aluminum mold will press composite

as it is heated. magnets are placed to align the material.

Hypothetical ideas are without meaning unless practical designs are

shared. This is how to do it. It's all pie in the sky.

What and how is quite different than "JUST DO IT" We can not expect

everyone to be a mechanic and scientist, and a Chemist and an inventor

plus a master rigger, these are talents possessed by the collective.

Everyone must share their gift or nothing gets off the ground.

.................................................. .....

Comment