EgmQC,

your almost right about that.

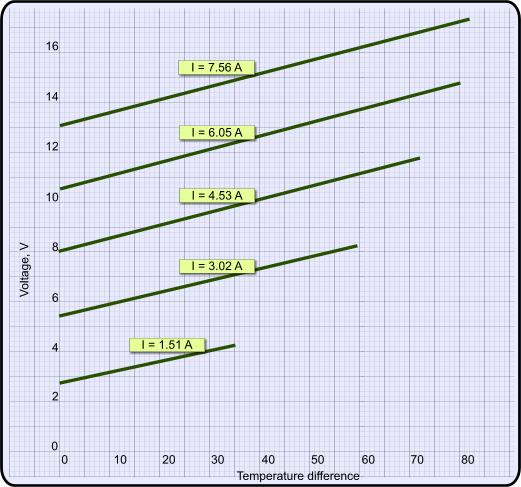

Peltier's do not have a linear I*V curve though.

They are also not the most efficient at max thermal displacement,

they have a sweet spot a little over 2/3 to max V allowed.

But reading all this I noticed one thing missing.

The potential thermal differential from anode to cathode.

Elias, you have presented very good talking points,

not many have noticed that their P/N junctions

respond efficiently to split shared thermal duty,

unlike resistive (watseful) heater arrangements.

I made beer cooler "Mugs" for people in my step-family.

I used induction transfer so the mugs

didn't need to be plugged in every time

the darned beer was set down.

Similar to the way toothbrush's are charged

when set down on their charging base.

A wallWart to a heavier short coil in the base,

a longer slightly lighter gauge coil in the mug base.

But the beer would only get so cold,

even though the Peltier was running

just above the 2/3 V point.

The solution to increase the thermal differential,

is to put two peltier's physically in series.

when you take a thick metal square

that has a reasonable amount of mass to it

and place it between two peltiers + and -.

You wind up with it electrically in series,

but more importantly you have now increased

the available potential thermal difference available.

Yes, you increase the V X2 to maintain proper I,

but you now have about 80% more thermal differential.

I wound up using two smaller peltiers instead,

conductive epoxy for the two peltier/plate joints,

connected the leads together too for good measure,

and fed the remaining two end leads to the

induction coil already in the beer mug base.

Moral to this,

and my point is.

They can be put both

electrically AND mechanically in series

to obtain better results and efficiency overall.

No, you don't get a full extra 100% with two,

my napkin-math was just under 80% with a second one.

I made a personal desk AC from

two huge eBay honkers later,

same principle, awsome results.

(8" muffin fan full boar = 46 degree air in a 78 degree room)

My plate was 1/2" thick copper because I was afraid

of a thermal transient due to one creating greater

thermal differential faster than the other one,

causing premature failure in the second one ...

These:

Gigantic 62mm - 545 Watt Thermoelectric Peltier Cooler - eBay (item 310135040904 end time Dec-02-10 05:47:44 PST)

Please note, these are not good ones,

there are better out there for sure ...

But you get my point.

Oh, and in the extreme magnetic field

of a Pantone/GEET assembly they shine.

They produce from both the heat and the field,

as Tutanka has indicated above.

They do not seem to do this as well

from regular coil/magnet fields my opinion.

Remember that peltiers made to generate electricity

are made and rated for a much higher temperature !

And that condensation is the enemy,

pot thyne apparatus well my son. LOL

Ask anyone that forgot to seal the edges of

a peltier CPU cooler arrangement before use ...

Anyway, just fodder for thought,

sorry for the crappy spellin'

your almost right about that.

Peltier's do not have a linear I*V curve though.

They are also not the most efficient at max thermal displacement,

they have a sweet spot a little over 2/3 to max V allowed.

But reading all this I noticed one thing missing.

The potential thermal differential from anode to cathode.

Elias, you have presented very good talking points,

not many have noticed that their P/N junctions

respond efficiently to split shared thermal duty,

unlike resistive (watseful) heater arrangements.

I made beer cooler "Mugs" for people in my step-family.

I used induction transfer so the mugs

didn't need to be plugged in every time

the darned beer was set down.

Similar to the way toothbrush's are charged

when set down on their charging base.

A wallWart to a heavier short coil in the base,

a longer slightly lighter gauge coil in the mug base.

But the beer would only get so cold,

even though the Peltier was running

just above the 2/3 V point.

The solution to increase the thermal differential,

is to put two peltier's physically in series.

when you take a thick metal square

that has a reasonable amount of mass to it

and place it between two peltiers + and -.

You wind up with it electrically in series,

but more importantly you have now increased

the available potential thermal difference available.

Yes, you increase the V X2 to maintain proper I,

but you now have about 80% more thermal differential.

I wound up using two smaller peltiers instead,

conductive epoxy for the two peltier/plate joints,

connected the leads together too for good measure,

and fed the remaining two end leads to the

induction coil already in the beer mug base.

Moral to this,

and my point is.

They can be put both

electrically AND mechanically in series

to obtain better results and efficiency overall.

No, you don't get a full extra 100% with two,

my napkin-math was just under 80% with a second one.

I made a personal desk AC from

two huge eBay honkers later,

same principle, awsome results.

(8" muffin fan full boar = 46 degree air in a 78 degree room)

My plate was 1/2" thick copper because I was afraid

of a thermal transient due to one creating greater

thermal differential faster than the other one,

causing premature failure in the second one ...

These:

Gigantic 62mm - 545 Watt Thermoelectric Peltier Cooler - eBay (item 310135040904 end time Dec-02-10 05:47:44 PST)

Please note, these are not good ones,

there are better out there for sure ...

But you get my point.

Oh, and in the extreme magnetic field

of a Pantone/GEET assembly they shine.

They produce from both the heat and the field,

as Tutanka has indicated above.

They do not seem to do this as well

from regular coil/magnet fields my opinion.

Remember that peltiers made to generate electricity

are made and rated for a much higher temperature !

And that condensation is the enemy,

pot thyne apparatus well my son. LOL

Ask anyone that forgot to seal the edges of

a peltier CPU cooler arrangement before use ...

Anyway, just fodder for thought,

sorry for the crappy spellin'

When the best COP of these devices happens to be around 0.5-1 A range!

When the best COP of these devices happens to be around 0.5-1 A range!

Comment