The motor I am using was rated for 12volts and 9 amps continuous. It came from a coolant exchange machine. It has a 12 segment rotor and 2 magnetic poles. The slots in the rotor are centered with 12 commutator segments. The timing is set to pulse the coil when it is in center of the two poles, were should the rotor be when pulsed? Also I can only change rotation by flipping the run battery connection.

Peace rawbush

Announcement

Collapse

No announcement yet.

Lockridge Device - Peter Lindemann

Collapse

X

-

crude first pronybrake attempt

Hi all

@ Matt

I am with Mark, it so a pleasure to hear you reporting your experiments in a so funny way. Thanks and go on ,but remember we NEED YOU ,so please be carefull.

@ all

I don't want to disturb here with my one pulse "Hall switched axial fluxed motor", but i have made a video that seems to be in accordance

with the searching of this thread.

I ,mean that it seems ,that as per my very crude and first prony brake testing , that the torque does not decrease with the increasing speed for the same applied voltage.

And it is probably valuable also for the radial brushed motors as MATT and others are using here.

( hope my glasses are not misleading me this time)

good luck at all

Laurent

YouTube - lockridge test 2

Leave a comment:

-

What motor are you running?Originally posted by Robbush View PostI re wound the motor trying to get as much in the slot as possible. I am using 22ga. because that's what I have. I impedance matched both to .6 ohms. The motor seems to run a bit slower on 12 volts then before, and I am filling a 25 volt cap to 5 volts in a few seconds. One thing I noticed is that I can run motor either direction and get same output on cap? The recover brushes are spaced one full commutator section apart, there is no overlap from the run brushes to the collector brushes, is this right? Next I need to find some more batteries to get the higher voltage. I am also working on lathing a shaft to install a flywheel, I have one from a treadmill that is about 8" in diameter. Any way, I just wanted to share were I'm at and thank all of you for your progress reports and Peter for helping out so much. More to come later. Peace rawbush

Matt

Leave a comment:

-

If you can run the motor in either direction than your timing is not right. You'll need to move where your wires are on the commutators.Originally posted by Robbush View PostI re wound the motor trying to get as much in the slot as possible. I am using 22ga. because that's what I have. I impedance matched both to .6 ohms. The motor seems to run a bit slower on 12 volts then before, and I am filling a 25 volt cap to 5 volts in a few seconds. One thing I noticed is that I can run motor either direction and get same output on cap? The recover brushes are spaced one full commutator section apart, there is no overlap from the run brushes to the collector brushes, is this right? Next I need to find some more batteries to get the higher voltage. I am also working on lathing a shaft to install a flywheel, I have one from a treadmill that is about 8" in diameter. Any way, I just wanted to share were I'm at and thank all of you for your progress reports and Peter for helping out so much. More to come later. Peace rawbush

Leave a comment:

-

re wound

I re wound the motor trying to get as much in the slot as possible. I am using 22ga. because that's what I have. I impedance matched both to .6 ohms. The motor seems to run a bit slower on 12 volts then before, and I am filling a 25 volt cap to 5 volts in a few seconds. One thing I noticed is that I can run motor either direction and get same output on cap? The recover brushes are spaced one full commutator section apart, there is no overlap from the run brushes to the collector brushes, is this right? Next I need to find some more batteries to get the higher voltage. I am also working on lathing a shaft to install a flywheel, I have one from a treadmill that is about 8" in diameter. Any way, I just wanted to share were I'm at and thank all of you for your progress reports and Peter for helping out so much. More to come later. Peace rawbush

Leave a comment:

-

Interesting. I don't have much experience/intuition with batteries, I guess.Originally posted by Matthew Jones View PostThat won't hurt your battery at all.

That's OK. I'm just thinking aloud. If anyone finds something wrong with what I wrote, I'll edit it out or footnote it.I have not got answer for ya on the other stuff.

pt

Leave a comment:

-

That won't hurt your battery at all.

I have not got answer for ya on the other stuff.

Matt

Leave a comment:

-

Add: my coil is 0.6 Ohms. That 2ms pulse is I = V/R = 8/0.6 = 4.8A. Will that help or hinder the battery?

pt

Leave a comment:

-

That ain't no joke. I thought I was dead for sure yesterday. LOLOriginally posted by dragon View PostThe barbell weight might be a little dangerous. Working with spinning weights it's probably best to spend the extra money and have something made correctly and balanced. The energy stored in a flywheel ( especially at the speeds Matt's little motor is running ) can be quite high and cause a lot of damage if "let free". Those experimenting with "quickie" set ups might want to invest in some kind of entrapment or cage around the flywheel. Far less expensive than a trip to the emergency room.

@PaulT

I gotta read your post a few more time and get my head wrapped around it, then I'll try to answer.

Matt

Leave a comment:

-

d'oh

Matt,Originally posted by Matthew Jones View PostPaulT

When you wound the thing did you put a diode on the end of the windings.

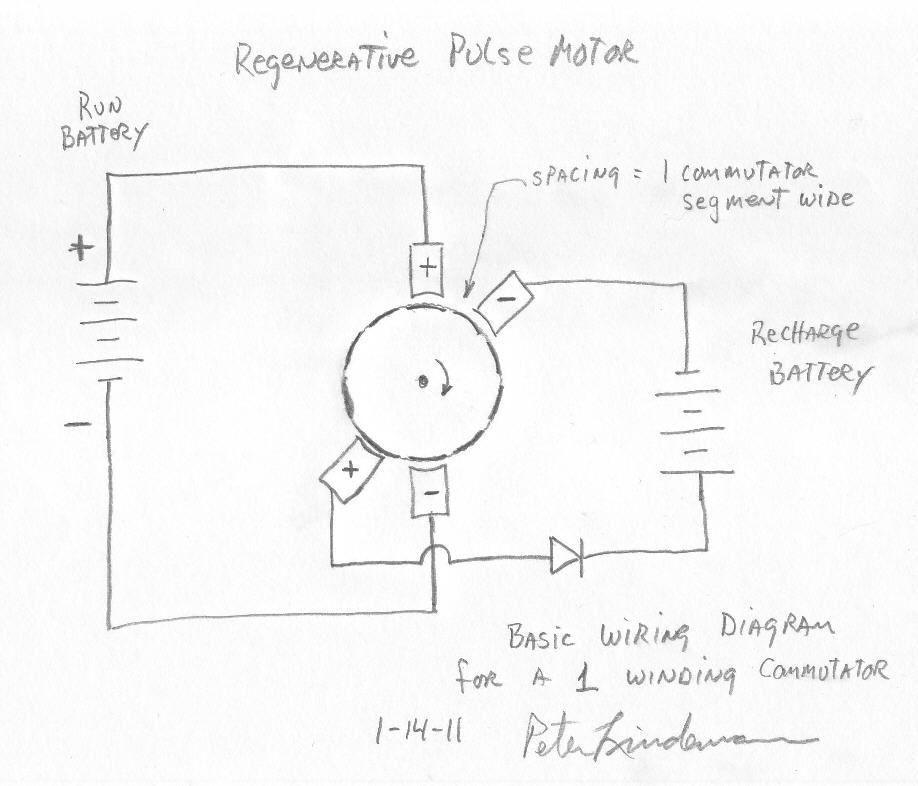

It turns out that the term "zig-zag" has been used two different ways in this thread. The current usage means a kinda side-saddle winding resulting in two coils like you've got. I have only one coil going through exactly two slots. My setup is like the one Peter originally drew - 1 winding commutator.

After mulling it over I do understand this scope trace:

I do understand this scope trace:

There is no visible spike because it is being smoothed by the attached recharge battery.

The -8v dip in the top trace (connected directly to the recharge brushes) is BEMF / charge. Just like Peter has been telling us. D'oh. It's only 2ms long because that's how long the recharge brushes are in contact with the coil. I'm still running this at +12V, so -8V of BEMF seems about right.

When I add a mechanical load and step up the voltage, I should see the % of this BEMF/charge drop relative to the run voltage.

I'm getting two pulses per revolution, 7ms between pulses * 2 = 14ms per revolution => 71 rps * 60 = 4,286 rpm at 12V with no mechanical load.

Hmmm, , there are 10 pairs of commutations per revolution, hence 10 units of BEMF. 2 units of BEMF are fighting the energization of the coil. 2 units are being pushed into the wrong end of the diode. 6 units of charge build up(?) in the coil (in 3-unit chunks) and do what? Create counter-magnetic fields inside the motor? Does a 3-unit lump of BEMF come spilling out when the run brushes are contacted?

, there are 10 pairs of commutations per revolution, hence 10 units of BEMF. 2 units of BEMF are fighting the energization of the coil. 2 units are being pushed into the wrong end of the diode. 6 units of charge build up(?) in the coil (in 3-unit chunks) and do what? Create counter-magnetic fields inside the motor? Does a 3-unit lump of BEMF come spilling out when the run brushes are contacted?

If we added 2 more pairs of brushes (a total of 2 run brushes and 6 recharge brushes), or made the recovery brush 3 commutators wide, we could "drain off" the charge (and do something useful with it?). That sounds too mechanically difficult and too expensive for the goals of this thread...

If I replace the single spike recovery diode with a FWBR, I should be able to capture the spike and send it to the recovery battery plus capture 2 units of BEMF and send that to the recovery battery, also, yes?

pt

Leave a comment:

-

The barbell weight might be a little dangerous. Working with spinning weights it's probably best to spend the extra money and have something made correctly and balanced. The energy stored in a flywheel ( especially at the speeds Matt's little motor is running ) can be quite high and cause a lot of damage if "let free". Those experimenting with "quickie" set ups might want to invest in some kind of entrapment or cage around the flywheel. Far less expensive than a trip to the emergency room.

________

Edsel iiLast edited by dragon; 05-11-2011, 11:21 AM.

Leave a comment:

-

barbell weight?

What about a cheap barbell weight from a fitness shop or wal*mart as the flywheel?

pt

Leave a comment:

-

I am defintaly going to the machine shop. Its gotta be better than just some jurry rigged thing. Also have to be able to attach the generator.

So I can kill 2 birds with one stone just my making the shaft of the flywheel couple with the shaft of the motor and or generator (Same thing).

Put some extra support in there with bearings and I'll get the speed.

I am just imagining what 120 volt will do....

Matt

Leave a comment:

-

LOL, Haha, Sorry but thats funny, got me laughing. I put that pot lid on a motor I had with a nut on the end and when I fired it up it tightened up the nut so tight I had to take the motor apart so I could grab a hold of it better to loosen the nut. I almost couldn't get it off, I threw a few cuss words at it and finally got it.Originally posted by Matthew Jones View PostJust the flywheel.

My shop is 40' long with 12' foot ceilings. It went around a good 6 times the long way. Smash my camera and left a few dent in the building.

It was scary. I went out the door pretty quik.

Matt

P.S. Sorry about the camera, thats not funny!

Leave a comment:

-

Just the flywheel.

My shop is 40' long with 12' foot ceilings. It went around a good 6 times the long way. Smash my camera and left a few dent in the building.

It was scary. I went out the door pretty quik.

Matt

Leave a comment:

Leave a comment: