Hey John Q

I think if we put the diode on the other recovery brush and run it to the positive of the charging battery it would work without transfering power from the primary.

Announcement

Collapse

No announcement yet.

Lockridge Device - Peter Lindemann

Collapse

X

-

john_g,

Peter said only two slots out of twenty on the commutator would be wound, from what I understand, and you have eleven sections shown on that commutator with about half of them represented as "wound" which I think is far too many. Increased number of sections, with fewer wound would be a more accurate representation. At least from what I understand.

Leave a comment:

-

Questions:

Wont power be transfered from the primary battery to the charging battery when the comutator is bridging both brushes at the same time?

Is this any different then a Newman motor other than the magnets and the coils are trading places? Except the problem that I stated in the first question which is easily solved with the Newman arangement.

Leave a comment:

-

Hi

I think this is what Peter means. Peter if I'm wrong please pm me and I will change as required.

Regards

JohnAttached Files

Leave a comment:

-

Peter,

First of all. Thank You for what you shared with us at the conference, and for continuing it here. As I understand it, the second set of brushes are connected through a diode directly to the second 36 volt battery bank, with no other circuitry.

As for the circuit providing power to the motor, is there a need for a commutator so that a constant voltage is not applied? You make no mention of this in the third part but a commutator is included in your description in part one.

Leave a comment:

-

DC Motor Modifications to Produce Regenerative Behavior

Hi folks,

OK. Sorry I don't have any diagrams to illustrate this. You will just have to picture it in your own mind from this description.

So, as I stated in the last post, there are two ways the electrical energy is lost in the motor, so there are going to be two, primary parts to the fix.

The first thing we are going to do is remove the rotor from the motor and remove all of the windings in all of the slots except ONE SET. So, for instance, if the rotor has 20 slots, then we will only leave wire wound through slots #1 and #11 and terminating on their corresponding commutator sections.

This modification will allow the motor to operate as a "pulse motor", producing TWO torque pulses per revolution of the shaft.

The problem with this, is that when the brushes move off of the commutator segments connected by this winding, the magnetic field will discharge and ARCH BACK to the brushes, burning the commutator up in short order.

The fix for this is to ADD a second set of brushes that engage the commutator exactly ONE COMMUTATOR SEGMENT width away from the main, power brushes. This second set of brushes will engage the commutator segments connected to the rotor winding exactly at the point when the power brushes disengage. So, now the magnetic field may discharge its stored energy back out of the motor through the second set of brushes. We will discuss where to send this electrical recovery impulse shortly.

The final issue is to bias the Back EMF downward on the graph shown in the previous post. To do this, we have to run the motor on a higher voltage than it was originally designed to do. So, for instance, if the motor was originally designed to run at 2000 rpm on 12 volts (as in the example above), then if we run it on 36 volts at 1000 rpm, we know it will produce 6 volts of Back EMF at that point. So, this is equivalent to running it in a position where 5/6ths of the voltage and current are getting through the motor. This suggests that we should be able to recover up to 3/4ths of our applied electricity on our secondary brushes without interfering with our torque production.

So, to summarize this example, we take a permanent magnet DC motor designed to run at 2000 rpm (in an unloaded condition) on 12 volts DC. We remove all of the windings on the rotor except ONE SET, and we add a second set of brushes to capture the collapsing field went the first set of brushes disengages. Then, we run this motor from a 36 volt battery bank and send the recovered energy to a second 36 volt battery bank, through a power diode to prevent reverse currents (like in a Bedini SSG circuit).

So, this is the very simplified set of modifications to turn a standard DC motor into a pulsed, high torque, regenerative motor. Add a flywheel to average the torque, and load the system to 1000 rpm and you are "good to go". This is the FIRST STEP in learning to build a "self running" machine, based on these principles.

None of these modifications should require a machine shop.

I hope this explanation is clear enough, and that you understand what I am trying to accomplish with these modifications.

PeterLast edited by Peter Lindemann; 01-09-2011, 11:41 PM.

Leave a comment:

-

Operations of a Commutated DC Motor

Hi Folks,

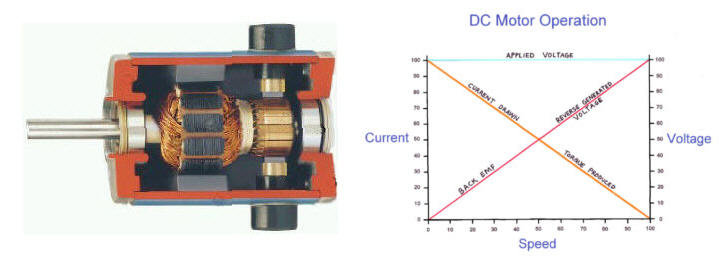

OK, here is the next installment. Below is an image of a DC motor and the chart of its operational characteristic.

For the sake of simplicity, we will discuss this with regard to a DC motor with a permanent magnet field, like the one shown in the drawing. Assuming nice round numbers, let us postulate that this motor will rotate at 2000 rpm on a 12 volt input with no load. So, we can see that the maximum POWER point is where the lines cross on the graph, when the motor is turning at 1000 rpm. Here, it generates 6 volts of Back EMF. Everyone who has seen my DVD should understand this pretty well.

Implied, but not said specifically in the DVD, is the following.

As we saw in the regenerative motor, the electrical energy should only be used to produce a magnetic field and then be recovered. So, what happens in the ordinary DC motor? Believe it or not, the same thing!

The problem is that the applied voltage that produces the magnetic field in the rotor is first reduced by half (at the power peak) by the Back EMF, and then when that magnetic field discharges (because the brushes move to the next commutator section) the electrical energy produced has nowhere to go except be SHORT CIRCUITED within the rest of the rotor windings.

So, the ordinary DC motor operates like a regenerative motor, except that ALL of the applied electricity that could be recovered is lost inside the machine. The first half of this energy is destroyed by the Back EMF, and the second half is shorted out in the machine.

Think about this very carefully. Take your time and think it through. The modifications to the motor to fix this situation are next.

PeterLast edited by Peter Lindemann; 01-09-2011, 10:48 PM.

Leave a comment:

-

Good Questions

Jetijs,Originally posted by Jetijs View PostHi Peter,

I have watched the DVD and it looks straight forward. But I have a question. Seems that everyone seeks a way to get rid of the generator function in a typical DC motor. Usually this generator effect is produced in the rotor windings as they move through a magnetic field thus creating BEMF and reducing input current. But what about the attraction motors? They don't have any field magnets or field coils, just stator electromagnets and a rotor made out of silicon steel that turns as it is attracted by the stator poles. So there are no two magnetic fields that are interacting and inducing BEMF. Am I right? So why isn't such a motor OU even without capturing the back spike? And how can I make my motors better based on the info on the dvd? I doubt that pulsing my motor coils once or twice per revolution with a HV cap will improve anything, but I can be wrong. I would appreciate your comment on this.

Thanks,

Jetijs

As usual, you are right on the money. However, I am going to postpone answering these questions until I have posted what I promised on Friday. The main part of the answer is that the attraction motors are "special" designs that require a machine shop to build, whereas the motor modifications I am taking about now require less tooling and skill.

Peter

Leave a comment:

-

Hi Peter,

I have watched the DVD and it looks straight forward. But I have a question. Seems that everyone seeks a way to get rid of the generator function in a typical DC motor. Usually this generator effect is produced in the rotor windings as they move through a magnetic field thus creating BEMF and reducing input current. But what about the attraction motors? They don't have any field magnets or field coils, just stator electromagnets and a rotor made out of silicon steel that turns as it is attracted by the stator poles. So there are no two magnetic fields that are interacting and inducing BEMF. Am I right? So why isn't such a motor OU even without capturing the back spike? And how can I make my motors better based on the info on the dvd? I doubt that pulsing my motor coils once or twice per revolution with a HV cap will improve anything, but I can be wrong. I would appreciate your comment on this.

Thanks,

Jetijs

Leave a comment:

-

Dragon is Right.

Bugler,

Dragon is right. Learn the little steps (lessons) first. The larger, more powerful designs will grow from these.

Peter

Leave a comment:

-

I don't think the discussion has come up yet about extracting energy from the system. To date has only been to generate enough energy to store in the cap to be discharged into the motor to create a self running motor/generator. The light is actually a "bonus" of this process and not an actual output. It has been mentioned about replacing the resistance load with a transformer for LED light production, still not an actual output in excess of what is required to maintain the system.

I believe that getting a system to self run should be the primary goal, this will be challenging in itself, then - when successful - move to enhancing the possibilities of generating energy in excess of the original process.

Not only does the motor need to be "tweaked" to provide an enhanced torque and recovery system, the generator will also need to be "tweaked" to provide a reduced drag while still producing a reasonable output.

One piece at a time....

________

PUBLIC AUTO INSURANCE ADVICELast edited by dragon; 05-11-2011, 11:14 AM.

Leave a comment:

-

More

I think this was mentioned before. Something about only putting out 300 watts.

I don't know about scaling up, but if you can put one smaller one together,then why not duplicate a number of them and hook them together for your desired output ?

FRC

Leave a comment:

-

Sorry if this has been discussed before.

What would be the way to scale up the regenerative motor? Let's say it gives a COP of at least 1.5 how do you go from a prototype to a bigger one producing an exccess of 5kw?

Thanks.

Leave a comment:

-

Features of a Regenerative Electric Motor

Hi Folks,

OK, let's get into this!!!

Here is a diagram of one type of regenerative motor.

The general formula is to invest a small amount of electricity into the creation of a magnetic field. Then use that magnetic field, while it exists, to perform some mechanical work. Then discharge that magnetic field and recover as much electricity as you can.

In the diagram above, you can see a very simple circuit, similar to the kind used in John Bedini's SSG type machines. This one is a little different in that the mechanical energy producing structure produces a closed magnetic field through the Iron Keeper and the Iron Rotor. When the Coil is turned on when the rotor is in the position depicted in the drawing, the Iron Rotor will have a strong tendency to align with the Iron Keeper. This is the "power stroke" of the mechanical energy production.

The production of this mechanical energy does not "consume" any of the electricity used to produce the magnetic field. When the input electricity is turned off, the magnetic field collapses and applies its recovered electricity back to the "recharge battery".

The amount of electricity that is recoverable is determined by the "state of the magnetic field" at the time it is turned off. In this case, the total energy in the field is lower than when it was turned on because the air-gap in the magnetic circuit has gotten smaller, not because the system has performed some mechanical work in the process. Still, between 65% and 70% of the applied electricity is recoverable in this situation. There are a wide variety of design changes that could be applied to raise the amount of recoverable electricity, but that is another story.

[Many of these issues have been discussed in the rather lengthy Electric Motor Secrets thread.]

The simplest way of thinking of this is to imagine that an "ideal" regenerative electric motor will only "borrow" the electricity to make a momentary magnetic field, perform some mechanical process with it, and then give most of the electricity back. Once this cycle of activity is complete, it can then be repeated over and over again. The net energy used in the system is the difference between the electricity used and the electricity recovered.

If we use the very modest numbers of 60% mechanical energy conversion and 60% electrical energy recovery, then the motor can produce a COP (Co-efficient of Performance) of 60/(100-60) = 60/40 = 1.5 COP.

So, this is the very simplified explanation of a regenerative electric motor.

Some of you are well acquainted with these ideas by now. For those of you just being introduced to this, don't over complicate the ideas at this point. It is more important for you to understand the general principle right now than it is to understand the specific operation of a given design.

PeterLast edited by Peter Lindemann; 01-08-2011, 04:38 AM.

Leave a comment:

-

Looking forward to new posts !

Now, having seen Electric Motor Secrets II. I was surprised to see the Lockridge

Bedini similarities. Currently I have been trying to assemble a sort of Lockridge-

Bedini hybrid using a small DC motor. So many of the builds in the other threads

are trying to make some kind or another motor from scratch, when we already

have a lot of the work already done for us by using existing motors and generators. The concept of modifications discussed here seem to be a much

easier path to follow.

FRC

Leave a comment:

Leave a comment: