Hi Paul, as you are using a 2 pole motor you might not get what we have. The device is simple but the interactions are complex.

We have a great increase in voltage on the unconnected winding.

what your trace does show is there is a transformer action. Put a low impedance load on the disconnected coil and shorten your pulses by 2/3rds.

better still get a four pole universal motor and ill tell you what to do and the basics of this is in my previous post. We need replicators to confirm results.

Remember this is just the motor/generator so don't expect great efficiencies yet. There is little BEMF on the motor so it draws high current.

We are in a process of elimination at this stage testing different armatures to see what happens and our results were better than I expected.

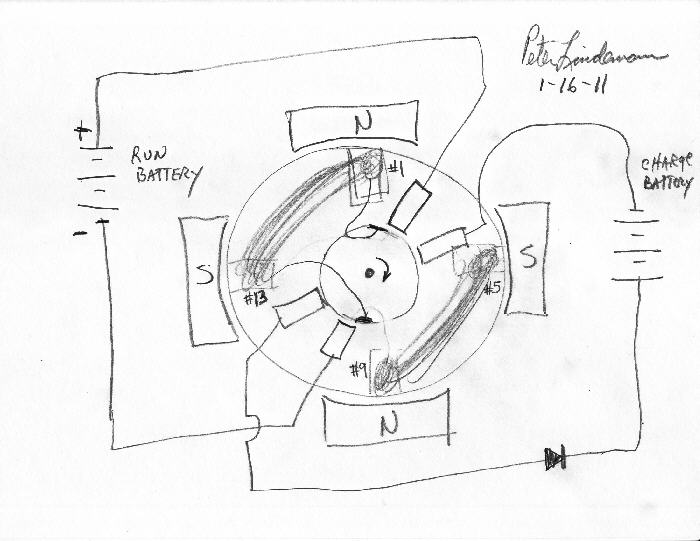

Take a close look at the FEMM drawing,there are a lot of clues in it. The red coils are the input and the green is the output. if the other two white coils are used' the 3 o'clock is powered and the six o'clock is an output. If you don't split the case you will only be able to use 2 stator coils and it will not perform as well. the black boxes represent the location of the carbon brushes.

With my design we have transformer and generator action in our output coils but I have not seen a scope trace yet.

We have a great increase in voltage on the unconnected winding.

what your trace does show is there is a transformer action. Put a low impedance load on the disconnected coil and shorten your pulses by 2/3rds.

better still get a four pole universal motor and ill tell you what to do and the basics of this is in my previous post. We need replicators to confirm results.

Remember this is just the motor/generator so don't expect great efficiencies yet. There is little BEMF on the motor so it draws high current.

We are in a process of elimination at this stage testing different armatures to see what happens and our results were better than I expected.

Take a close look at the FEMM drawing,there are a lot of clues in it. The red coils are the input and the green is the output. if the other two white coils are used' the 3 o'clock is powered and the six o'clock is an output. If you don't split the case you will only be able to use 2 stator coils and it will not perform as well. the black boxes represent the location of the carbon brushes.

With my design we have transformer and generator action in our output coils but I have not seen a scope trace yet.

I really liked your lecture and also when you shared your permanent magnet DC arrangement

I really liked your lecture and also when you shared your permanent magnet DC arrangement . Thanks so much! A lot of the links from that person that would not listen to you guys seem to be dead...maybe "high winds do not last all day." I'll keep at it!

. Thanks so much! A lot of the links from that person that would not listen to you guys seem to be dead...maybe "high winds do not last all day." I'll keep at it!

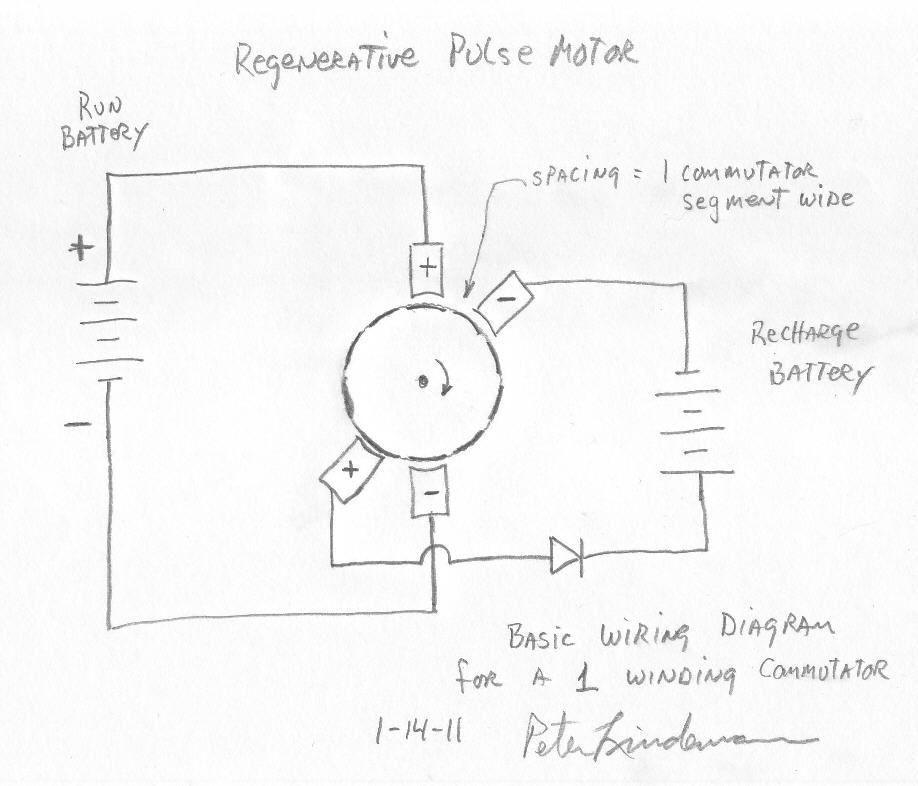

. My brushes are spaced a little less than 1 commutator segment and the diodes I am using are in motor NTE 598 600V 8A ultra fast and on recovery batteries UF 804 same specs I think. I have recovery side diode on a clip lead going to recovery battery positive. Highest I can go right now is about 34V, still notice the spike there, maybe if I go faster, things will change?

. My brushes are spaced a little less than 1 commutator segment and the diodes I am using are in motor NTE 598 600V 8A ultra fast and on recovery batteries UF 804 same specs I think. I have recovery side diode on a clip lead going to recovery battery positive. Highest I can go right now is about 34V, still notice the spike there, maybe if I go faster, things will change? . The motoring action comes from the generating coils

. The motoring action comes from the generating coils

Comment