Great work Excalibur. Keep us posted.

Announcement

Collapse

No announcement yet.

How to turn plastic waste into diesel fuel cheaply

Collapse

X

-

I have been running various blends of waste oils and unleaded gasoline in a 1983 Chevy G-20 van with a 6.2L diesel V-8 engine, with a Stanadyne Rotary DB2 IP since Feb, 2007. I have started the engine with no difficulty and no block heater on an 80/20 (WVO/gas) blend down to 0F (-18c). I have found that by blending as little as 15% gasoline in the summer, and as much as 50% in the winter, my engine starts and runs as if it was running on diesel fuel.

-

I use 2 different sealants on my pipe work. Furnace cement, based on sodium silicate, for the joints nearest the retort. This stuff is good for up to 2000c but is brittle so the joint must be totally rigid. On all other joints I use high temperature silicone mastic, Bondit HT30. Its good up to 300C and is flexible.

Comment

-

Thanks

The turk is run on waste mineral oil/gasoline blend approximating the weight of diesel. Eventually the plan is you use the gasoline that the retort makes for the blend. The turk, IP and injectors didn't seem to be fussy on the fuel though it behaves much better once its' up to temperature. The efficiency is significantly better over my earlier drip feed turk iteration.

The diesel has come out dark and the gasoline much lighter. Really, I haven't been too concerned about the fuel quality but concentrating on getting the temperature stable. I appear to have made good progress with the latest prototype modification. I've read about the fuel oxidising problem but I haven't noticed any of mine deteriorating, even that which had some plastic. Actually, I thought it was the plastic fuel that was giving the problem.

Amongst other upgrades, I'm planning to build a new condenser trap and I've started rounding up the materials. I need much better control of the temperature which I want to fine tune to suit the application.

Thanks for the ideas on joint sealants.

Comment

-

Good ideas imakebiodiesel, I recently picked up a tube of the NAPA brand Copper antiseize lubricant. I will report back on how it does.Originally posted by imakebiodiesel View PostI use 2 different sealants on my pipe work. Furnace cement, based on sodium silicate, for the joints nearest the retort. This stuff is good for up to 2000c but is brittle so the joint must be totally rigid. On all other joints I use high temperature silicone mastic, Bondit HT30. Its good up to 300C and is flexible.

Back in the 80s all anti-seize compounds were molybdenum-based, and I found they worked fine for sealing up pipe threads on cat cracking units that I worked on. I have found putting anti seize compound on the threads of plumbing fittings that will be used at high temperatures will help seal them, and make it easier to service the fittings at a future date even up to temperatures of 1200F (650c).

On my forum Excalibur suggested Nickel antiseize by Loctite, and something called CopperCote. I think they are worth checking into as well.I have been running various blends of waste oils and unleaded gasoline in a 1983 Chevy G-20 van with a 6.2L diesel V-8 engine, with a Stanadyne Rotary DB2 IP since Feb, 2007. I have started the engine with no difficulty and no block heater on an 80/20 (WVO/gas) blend down to 0F (-18c). I have found that by blending as little as 15% gasoline in the summer, and as much as 50% in the winter, my engine starts and runs as if it was running on diesel fuel.

Comment

-

hy all..i just read some page and i already make out some oil, and its cool..and i wanna to ask some questions,

1)I got a layer of something in bottom of my oil, is it true, i need pyrolisis it once again?

2) if we make oil from Polyethelyne or polyprophelyne and have some water or paint on it, can its still produce an oil?whats happen if our waste have some water?

3) can we really make diesel for today truck?what the important point for making diesel oil for truck?like separate gasoline and diesel to avoid pre-detonation, remove parafin, is it something else?

4)as i know some factory produce plastic that they mix with calcium,resin or something else, can we still make safe diesel for truck?like didnt make the machine dirty,corrosion or other trouble?

and im sorry im not good in english, hope some of experience guy here answer and explain it for me..

imgur: the simple image sharer

imgur: the simple image sharer

Comment

-

Hi xyverster. welcome to the thread. Your outfit is the simplest Ive ever seen but it obviously works. The high loop of copper pipe works as a reflux on the way up and a condenser on the way down. The brick on the lid is an effective if a bit crude pressure relief valve. Well done liquid fuel first time.

Its difficult to know for sure from the picture but the dark layer in the bottom of the fuel may be water. Any moisture in the retort will boil out and be captured in your condenser.

Paint , glue etc will contain some volatiles which will boil out and mix with your fuel and also some non volatiles that will stay in the retort and become char

Your question about fuel quality is a good one and one that we must all consider carefully. 10 or 15 years ago diesel engines were typically simple robust machines that could run happily on a wide range of fuels. Many people would have mixed vegetable oil with their diesel or like Beyond Biodiesel mixed finely filtered waste motor oil with petrol to make up a fuel.

Scince 2000 most car and van makers in Europe have adopted common rail injection systems or other high pressure injection systems. This new type of engine will not tolerate even slightly off spec fuel and serious and expensive damage can be done in a very short time.

My advice to anyone who wants to experiment with fuels is to buy an old, late nineties, diesel vehicle with a rotary injection pump, mechanical injectors and if possible indirect injection. These engines are very tolerant of fuel quality and if the worst comes to the worst, spare parts are cheap and easily available from breakers yards.

Looking into the future it would be a good idea to devise a set of simple standardized tests that would allow small scale plastic to fuelers to assess the quality of their fuel and compare it with others. In the Biodieselinfopop forum we have done exactly that and the result is that most members now make fuel well above the minimum spec.

Comment

-

Nice photos waterboost. What are you using for seals?

It could be water, or uncracked plastic. If it is thick or solid, then put it back in for another run with your next batch. If is is thin, like water, then dump it.Originally posted by xyverster View Posthy all..i just read some page and i already make out some oil, and its cool..and i wanna to ask some questions,

1)I got a layer of something in bottom of my oil, is it true, i need pyrolisis it once again?

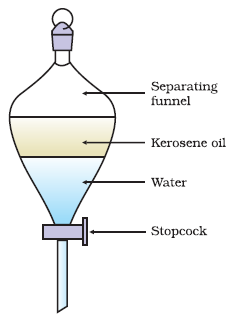

Water is a common by product of pyrolysis, so just use a separation flask to separate out the water.Originally posted by xyverster View Post2) if we make oil from Polyethelyne or polyprophelyne and have some water or paint on it, can its still produce an oil?whats happen if our waste have some water?

Sure why not? Although, I agree in part with imakebiodiesel. If you are going to experiment with making your own fuel, then run it on a cheap disposable engine first. When you can keep a cheap auto running for a year without trouble, then you may have figured it out and it would be time to try it on a more expensive vehicle.Originally posted by xyverster View Post3) can we really make diesel for today truck?

As imakebiodiesel revealed I have been blending waste oils with gasoline for 6 years to run on my diesel engine, which is 30 years old. On the other hand on my forum there are people making fuel like I make it, and running it on diesel engines that are less than 10 years old, and not having problems.Originally posted by xyverster View Postwhat the important point for making diesel oil for truck?like separate gasoline and diesel to avoid pre-detonation, remove parafin, is it something else?

So, my method is not to worry about what is in solution, but remove what precipitates out, filter it, and check the specific gravity and viscosity of the fuel blend to make sure that it is close to diesel fuel. Thus pre-detonation is a non issue.

Just settle then filter your fuel before you run it.Originally posted by xyverster View Post4)as i know some factory produce plastic that they mix with calcium,resin or something else, can we still make safe diesel for truck?like didnt make the machine dirty,corrosion or other trouble?

Your English is fine. I to am impressed with the primitive machine you made, but as you scale it up you are going to want to make sure you make it safe.Originally posted by xyverster View Postand im sorry im not good in english, hope some of experience guy here answer and explain it for me..

I have been running various blends of waste oils and unleaded gasoline in a 1983 Chevy G-20 van with a 6.2L diesel V-8 engine, with a Stanadyne Rotary DB2 IP since Feb, 2007. I have started the engine with no difficulty and no block heater on an 80/20 (WVO/gas) blend down to 0F (-18c). I have found that by blending as little as 15% gasoline in the summer, and as much as 50% in the winter, my engine starts and runs as if it was running on diesel fuel.

I have been running various blends of waste oils and unleaded gasoline in a 1983 Chevy G-20 van with a 6.2L diesel V-8 engine, with a Stanadyne Rotary DB2 IP since Feb, 2007. I have started the engine with no difficulty and no block heater on an 80/20 (WVO/gas) blend down to 0F (-18c). I have found that by blending as little as 15% gasoline in the summer, and as much as 50% in the winter, my engine starts and runs as if it was running on diesel fuel.

Comment

-

Seals

I think the seals are all stainless compression fittings.

The loading access one on the reactor top will have a glass fibre high pressure furnace seal.

The only one that concerns me is the tap fitted to the first condenser (basket filter) which I amicably refer to as the cheese pot, even though I hope not to see any cheese in there... I havent checked it yet, it may need replacing for an all metal ball or gate valve...

Comment

-

There are now quite a few out there doing this and if we are to compare results in a sensible way we need to standardize a little. Im proposing a set of simple cheap tests that everyone can do but we need to agree to the same standards for the results to be useful.

The first test has to be to establish what is in the crude fuel produced by pyrolysis. Even in a setup with multiple condensers the fuel produced is likely to be a mixture. I outlined a test a few pages back that I think works well.

THE BP TEST.

A 100 gm sample of crude liquid fuel is placed on an electric hotplate and brought up to 175C for 30 minutes in a well ventilated place. After that it is weighed and the missing grams are the petrol/gasoline content. The remaining sample is now heated to 260C for 30 minutes and weighed again. The missing grams are kerosene and the remaining weight is diesel.

I know that these boiling points are open to discussion so please lets hear your views.

Once the fuel is separated into one of the three fractions then there are various tests we can do with very basic equipment. Beyond Biodiesel's suggestions of viscosity and specific gravity would be very useful and I think flash point would be a good addition.

Comment

-

I agree... excellent test... I have an industrial oven that should hold about 90 litres. I've asked a friend to make a stainless tank that sits inside with a pipe for the vapour from the top and then connected to a condenser....

The oven accurately controls the temperature and there is also a seperate temp gauge... I was looking forward to playing with specific fractions

Comment

-

I think a way of standardizing a test of fuel samples is a good idea, but wouldn't just using hydrometers be a safer and more accurate test of fuel grade. It is what the petroleum industry uses, and hydrometers are relatively cheap.Originally posted by imakebiodiesel View PostThere are now quite a few out there doing this and if we are to compare results in a sensible way we need to standardize a little. Im proposing a set of simple cheap tests that everyone can do but we need to agree to the same standards for the results to be useful.

The first test has to be to establish what is in the crude fuel produced by pyrolysis. Even in a setup with multiple condensers the fuel produced is likely to be a mixture. I outlined a test a few pages back that I think works well.

THE BP TEST.

A 100 gm sample of crude liquid fuel is placed on an electric hotplate and brought up to 175C for 30 minutes in a well ventilated place. After that it is weighed and the missing grams are the petrol/gasoline content. The remaining sample is now heated to 260C for 30 minutes and weighed again. The missing grams are kerosene and the remaining weight is diesel.

I know that these boiling points are open to discussion so please lets hear your views.

Once the fuel is separated into one of the three fractions then there are various tests we can do with very basic equipment. Beyond Biodiesel's suggestions of viscosity and specific gravity would be very useful and I think flash point would be a good addition.I have been running various blends of waste oils and unleaded gasoline in a 1983 Chevy G-20 van with a 6.2L diesel V-8 engine, with a Stanadyne Rotary DB2 IP since Feb, 2007. I have started the engine with no difficulty and no block heater on an 80/20 (WVO/gas) blend down to 0F (-18c). I have found that by blending as little as 15% gasoline in the summer, and as much as 50% in the winter, my engine starts and runs as if it was running on diesel fuel.

Comment

-

There is no doubt that Specific gravity is the easiest and most useful test of a given fuel. Hydrometers are relatively cheap and even if you cant stretch to that simply weighing one litre of the fuel in grams and dividing by 1000 will do the same job.

Fuels derived from plastics have lower sg than ordinary fuels because of the presence of isomeric alkenes and the absence of aromatic compounds. This is especially true of the heavier fractions such as diesel

Normal diesel can contain as much as 25% aromatics and these are very dense producing diesel fuel in Europe with a sg of 0.845, Diesel from plastic pyrolysis will average 0.81.

Likewise with Kerosene, normal kerosene is 0.80 while kerosene from plastic will be 0.78/

Normal petrol is 0.74 and petrol from plastic will be about the same.

So the sg test is very useful once you have an identifiable fuel but it will not help us when we have an unknown mixture of the three fuels.

The BP test establishes what a mixture is composed of, while the SG and to a lesser extent viscosity and flash point tells us the quality of the separated fractions.

Comment

Comment