Originally posted by Beyond Biodiesel

View Post

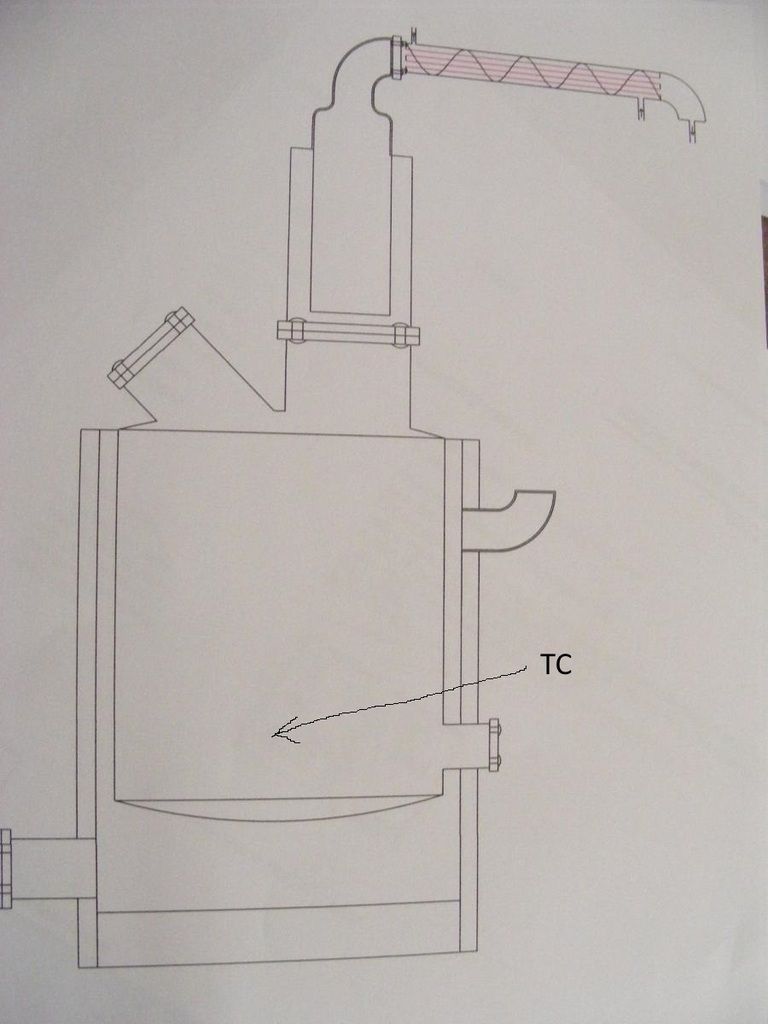

The thought about greater control with electric heaters highlights the challenges faced with diesel fired heating. I regard the type of heat generated by electric elements as "soft heat", quite unlike the fierce, ferocious heat from a high powered burner. Recent revamp of my plant was an attempt to reduce any overheating of the steel retort vessel and refractory. In addition my burner is adjustable for heat output from nil to 1000°C+. I can match exactly the heat requirement of retort contents. For example once the retort reaches optimum temperature as shown by output flow in the sight glass, then flame temperature may as well be reduced to a figure slightly above retort.

Waste oil feedstocks should be regarded as likely having multiple fractions. Lighter fractions should be boiled off before raising temperature to the boiling point of the next lightest fraction.

BB's description of fuel produced from clear to amber indicates it was made at a rate it was happy to be distilled at, unhurried and allowed to proceed at the pace it wanted. Clearly we cannot apply unlimited heat and expect all to be well. Best to apply heat to closely match the requirements of the liquid we are distilling.

Leave a comment: