Originally posted by wheels

View Post

Announcement

Collapse

No announcement yet.

How to turn plastic waste into diesel fuel cheaply

Collapse

X

-

Thanks for the replies. Well, my plan is that after i have processed a full batch within 4 - 5 hours, i will remove the insulation on the top part of the retort and i have noticed from my current small unit that after about an hour the temperature drops to about 250 deg celc. I will then open the lid and then start adding more plastics when temp is around 160deg, close and tighten the lid and start heating again.Originally posted by Beyond Biodiesel View PostThe real problem will be how to cool off your reactor quickly enough to load it again in a 24 hour period. My reactor tended to be 100c after 12 hours of cooling.

The other issue that you will have to deal with is decoking the inside of your reactor. You will have to do it from time to time, because coke is an excellent insulator, so you will see that it will take more and more fuel and/or more time to get to your control point as the coke layer grows from successive run cycles.

Also the reactor will have to be almost ambient temperature to manually .

Leave a comment:

-

Thanks, Excalibur, for sharing the new photos. Your system is looking very professional.

6mm Mild Steel seems plenty thick enough to me. 425c is not very high temperature, so oxidation on the outside is not likely to be significant, and the inside is going to be coated with coke, so it will be protected.Originally posted by Babataku View PostHi All,

I am planning an upgrade to a system that can process 200Kg of Plastic per Batch. I plan to heat this using a light oil / Diesel Burner rated at 30Kw. I intend to have a max of 2 Runs per day. I will use a Mild Steel tank of 6mm thickness guage and will be placed in direct contact of the burners flame.

My question is how long can this material last (6mm Mild Steel), if i have 2 runs per day? How often do you think i will need to replace the tank due to the constant heat cool cycles / metal fatigue& Cracking? i dont mind replacing every 6 - 12 months...Mild steel is cheaper and readily available in my country..

Any advice...

The real problem will be how to cool off your reactor quickly enough to load it again in a 24 hour period. My reactor tended to be 100c after 12 hours of cooling.

The other issue that you will have to deal with is decoking the inside of your reactor. You will have to do it from time to time, because coke is an excellent insulator, so you will see that it will take more and more fuel and/or more time to get to your control point as the coke layer grows from successive run cycles.

Also the reactor will have to be almost ambient temperature to manually scrape off all of the coke.

The petroleum industry burns the coke off by raising the temperature of the retort to 650c once all of the volatiles have been evaporated. Then air, or O2 is metered in. You do it slowly at first, while closely monitoring the retort temperature.

At first when O2 is admitted the retort temperature will rise. You just regulate the O2 or air to keep the temperature at 650c. When all of the coke has been burned you will see the temperature start to drop off sharply. That is when you can shut off the O2 or air inlet, let the retort drop to 425c, then purge the O2 out, and blow the ash out a bottom valve, then add more melted plastics to start your next run.

Leave a comment:

-

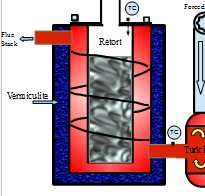

Jonathan.. In this schematic example the retort is surrounded by (red)flame... which is in turn surrounded by (blue) insulation!

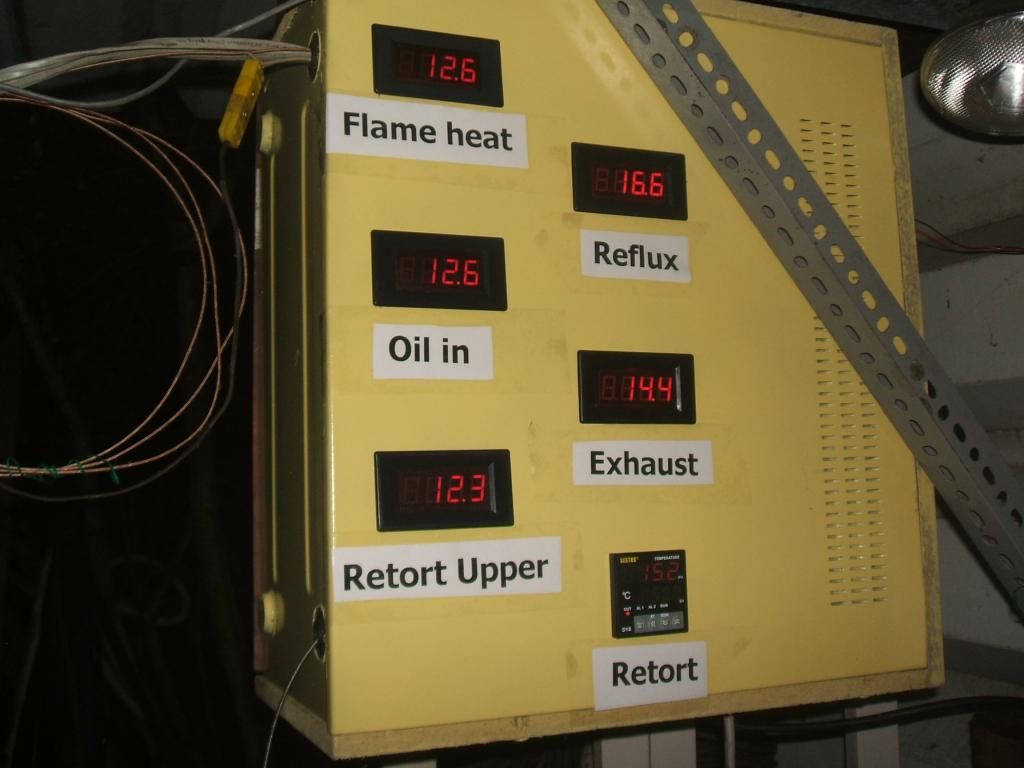

The Orion instrument panel. All run from K-type TC. The housing is a recycled PC chassis with wooden sides. To be tested shortly.

Leave a comment:

-

retort problem

thanks excalibur for help. i will try like as you said.but how can i heat 90% of retort with gas burner. are you meaning that i leave gas burner heat the base of retort and put retort in oil barrel insulated

Leave a comment:

-

It's great that you are using a test model to try things out on. They are quick and cheap to add changes to. Start by buying some more k type thermocouples. Put one in the retort. Another could go on the flame temperature. Get these reading known good values and then work on any other problems that arise.Originally posted by jonathan View Postthanks excalibur l dont have probe in retort but i think retort tempreture was hi enough. do you think retort tempreture was low or too hi? or it can be because there is to much wind because i have insulation on retort/reflux only? thanks

If you are only heating the base of the retort vessel, this is likely to be causing frustration. I think heating 80 -90% of the retort vessel outer area is a good target. The insulation should be outside of that heat zone.

I recorded some temperatures recently when my plant was really working well with an excellent flow rate cracking WMO.

Retort 397°C

Reflux 339°C

Flame heat 439°C

Exhaust stack 240°C

These readings should be regarded as a 'snapshot' only. The next run will see more insulation for the retort plus a revised retort probe.

Leave a comment:

-

retort problem

thanks excalibur l dont have probe in retort but i think retort tempreture was hi enough. do you think retort tempreture was low or too hi? or it can be because there is to much wind because i have insulation on retort/reflux only? thanksLast edited by jonathan; 08-02-2014, 05:32 AM.

Leave a comment:

-

retort problem

thanks excalibur l dont have probe in retort but i think retort tempreture was hi enough. do you think retort tempreture was low or too hi?

Leave a comment:

-

Heating and cooling cycle

Heating and cooling cycle will be facing thermal fatigue and so one has to be careful while selecting the thickness of plate for reactor . One should consider thermal fatigue property while designing batch type reactorOriginally posted by wheels View PostYou shouldn't have too much of an issue with the heating/cooling in this situation. The heat is constant for the run time and then it cools. That is very different to a rotating vessel going in and out of the heat constantly. In your case, it will be the inside of the vessel you will need to keep an eye on, due to the acids that are created which will slowly eat away at the inside of the vessel. However, that is not to say that you should ignore the outside of the vessel. You still need to inspect it often to ensure all is well.

Leave a comment:

-

My guess is the volume of vapor generated by the retort declined so this was reflected in reduced reflux temperature. What was the temperature of the retort throughout this test?Originally posted by jonathan View Postmy uncle give me some exhaust insulation wrap and i am doing some tests.i have question. i make pressure cooker to a 3l glass condenser. i try lunchbags in small pieces and i got over 0.5 litres. in 5 hours with small gas burner.my question is this i try it another time but i dont cut the lunchbags in small pieces i fire the gas burner and after 2 hours reflux tempreture was 330degrees celcius but no oil coming out after a while reflux tempreture begun decrease to 253 i leave it for 6 hours and i find about 0.3 litres oil. i was thinking why it take over 8 hours and tempreture decrease. do you thing because i dont cut them in small pieces? thanks in advance

On Monday I'm doing some testing. I'll have two probes in the retort so hopefully something can be learnt regarding probe placement, retort behavior, etc

Leave a comment:

-

Yes, of course. The vertical inclined outlet pipe leading to the reflux vessel will itself be a reflux. Even lagging it may not be enough as the outright pipe temperature ideally should be at (or above) kiln temperature.Originally posted by sunilkm153 View Postonce again excalibur without indulging into unnecessary complications you simply made your suggestion I also tried to elevate reflux height to get heavy condensate directly piped to kiln's inlet but in that case I had very low output of oil I thought in that case gas velocity and temperatures both get reduced which finally affects yield of oil now I am planning to insulate & heat the pipe between reflux and kiln to regain temperature and gas velocity if it still don't work simply I will try to replicate your second suggestion dear friend soon I will post pictures

Two options come to mind. 1/. Maintain the pipe at kiln temperature, or 2/. position the reflux below the outlet and pump any condensate to the kiln infeed.

Hope this is helping. Pics would be great. Thanks.

Leave a comment:

-

You will be surprised at how well Mild Steel lasts. Unless you use a very exotic SST, Mild steel is the best choice. Remember that there is, or should be no oxygen, so you do not get corrosion on the inside. You do get etching from the Acids though, so the Steel will slowly eat away. Mild steel withstands the heating and cooling cycles far better than most other metals. If the seams have been welded with mild steel electrodes, the welds behave just like the rest of the vessel metal. But if it has been MIG welded, MIG weld is hard low Hydrogen and will present a "different metal"composition at the weld interface. Two different metals, even though they are both steel, can cause a galvanic action with the Acids and heat. So the Welds need to be inspected regularly.Originally posted by sunilkm153 View Post200 kgs of plastic per batch and two batches per day and heated through direct flame 6mm mild steel will not withstand longer also security concerns are there instead try to get 10mm thickness

Wall thickness of 6mm is not too bad for 200ltrs, but I wouldn't go any larger in vessel without increasing the wall thickness. Certainly 10mm would last longer, but remember you also need to get the heat through the vessel wall efficiently. Plus the cost of rolling a vessel with 10mm wall thickness and not to mention the vessels weight would make anything heavier much more difficult.

Leave a comment:

-

You don't have to use a Reflux vessel. Reflux is just a simple way of returning the very heavy fractions back to the retort so they can be heated again and hopefully cracked. You can forget the reflux vessel and crack the heavy fractions in it's very own vessel as part of the distilling process. You can even use a catalyst to speed up the process and for the need of less heat, at that point as well.Originally posted by sunilkm153 View Postonce again excalibur without indulging into unnecessary complications you simply made your suggestion I also tried to elevate reflux height to get heavy condensate directly piped to kiln's inlet but in that case I had very low output of oil I thought in that case gas velocity and temperatures both get reduced which finally affects yield of oil now I am planning to insulate & heat the pipe between reflux and kiln to regain temperature and gas velocity if it still don't work simply I will try to replicate your second suggestion dear friend soon I will post pictures

Earlier I asked about how you control the heat with the PID or whatever you are going to use. I was meaning, how does the temp device actually control the heat? I assume it is controlling the fuel in someway, but just wondered how.

Leave a comment:

-

200 kgs of plastic per batch and two batches per day and heated through direct flame 6mm mild steel will not withstand longer also security concerns are there instead try to get 10mm thicknessOriginally posted by Babataku View PostHi All,

I am planning an upgrade to a system that can process 200Kg of Plastic per Batch. I plan to heat this using a light oil / Diesel Burner rated at 30Kw. I intend to have a max of 2 Runs per day. I will use a Mild Steel tank of 6mm thickness guage and will be placed in direct contact of the burners flame.

My question is how long can this material last (6mm Mild Steel), if i have 2 runs per day? How often do you think i will need to replace the tank due to the constant heat cool cycles / metal fatigue& Cracking? i dont mind replacing every 6 - 12 months...Mild steel is cheaper and readily available in my country..

Any advice...

Leave a comment:

Leave a comment: