Hello guys, i see you are talking about a injection machine, i think it is very interesting subject, so i'we done a little reasearch and come across this. Maybe it can be addapted to our cause, upscalled, any opinions?

Home Plastic Injection Molding

Announcement

Collapse

No announcement yet.

How to turn plastic waste into diesel fuel cheaply

Collapse

X

-

Interesting idea on feeding solid plastic into a continuous fired retort. I expect that, as you mentioned, light plastics, such as polyethylene will not gravity flow. Also, at some point along that pipe it is going to be hot enough to melt plastic, and the plastic is going to stick there, and stop rolling down hill.Originally posted by Col View PostFor everyone using plastic as feedstock here's as idea for continuous feeding of plastic into the retort -

Col

Over the weekend I reflected on another idea for continuous feed system based upon pneumatic pumping. A large retort with a cone shaped bottom and a wide seal-able top could be filled with your feed stock, then the lid closed, then heated to the transition temperature of the plastic feed stock. The pressure vessel is pressurized using an inert gas, such as CO2 to about 5-10 PSI. Then a lower valve is opened and the now liquid feed stock will move into the retort at whatever rate you want, and you close the valve if you want to stop the feed.

The valve would have to be able to handle the temperature of your plastic feed stock at its transition temperature.

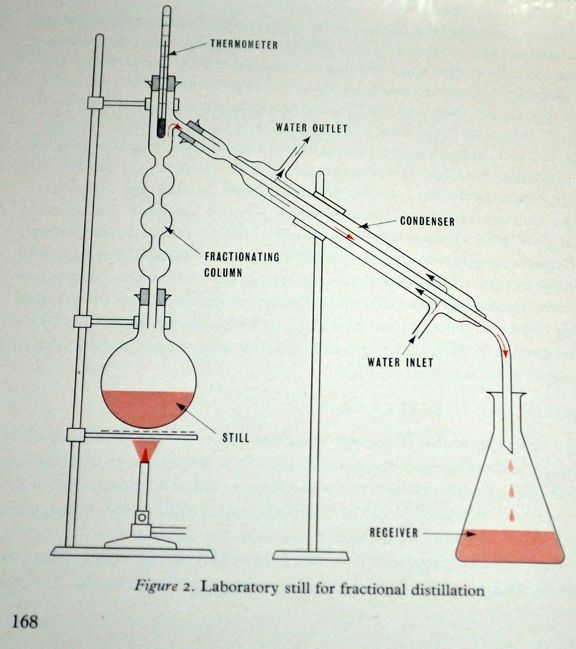

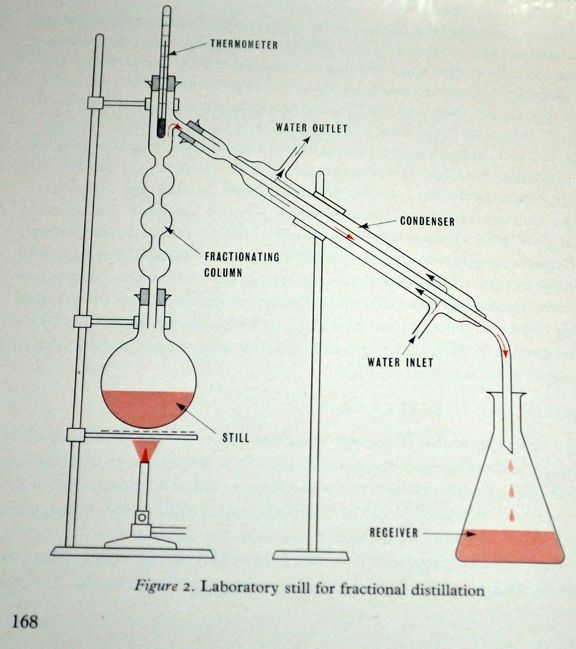

The illustration shows just how much volume is needed to avoid boil-over, but anyone who has operated one of these glassware fractionation columns, as I have, will know, if the retort is heated too aggressively, then it will boil-over, so the temperature has to rise slowly.Originally posted by Col View PostNote how much surface area is available for evaporation. In laboratory scale experiments like this I believe they never fill the round bottom flask any higher than half full because when you go above that level the surface area begins to reduce. When the surface area is small relative to the volume being boiled I understand the vapours struggle to escape fast enough (depending on how much heat you are putting into the flask) and the reaction is impeded. I do not remember what the consequences are. So a larger relative diameter is better then a smaller diameter for facilitating evaporation.

Col

A more typical arrangement in a working lab would be using electric heating mantels closely controlled by variac, instead of the bunsen burner, and the operator would have to bring the temperature up very slowly to avoid boil-over.

Leave a comment:

-

surface area available for evaporation of vapours

Note how much surface area is available for evaporation. In laboratory scale experiments like this I believe they never fill the round bottom flask any higher than half full because when you go above that level the surface area begins to reduce. When the surface area is small relative to the volume being boiled I understand the vapours struggle to escape fast enough (depending on how much heat you are putting into the flask) and the reaction is impeded. I do not remember what the consequences are. So a larger relative diameter is better then a smaller diameter for facilitating evaporation.Originally posted by Beyond Biodiesel View PostBabataku is right. Also, your condenser should not be horizontal, but face down. See an illustration of the basic fractionation column from the Petroleum Handbook.

Col

Leave a comment:

-

continuous plastic feed to retort

For everyone using plastic as feedstock here's as idea for continuous feeding of plastic into the retort -

You'll need a vertical/sloped pipe running from the hopper to the retort with a series of valves in it. Once the plastic is in small pieces, dry and in the hopper, open a valve to dump a quantity of plastic pieces into the pipe, maybe the section of pipe would be 300-600mm long and 50-100mm diameter? Close the valve, now the plastic is trapped between two closed valves, with air mixed in with it. There needs to be a small gas inlet valve at the bottom of this section of pipe and a small gas outlet valve at the top of this section of pipe. Choose your gas supply (could be off-gas stored from previous runs, could be an inert gas or could be LPG for instance) and feed it into the section of pipe. This gas will fill the chamber from the bottom and work it's way up to the outlet valve near the top. It will hopefully push MOST of the air out and leave MOSTLY the introduced gas in it's place. Then repeat this procedure down into the next section of pipe and so on as many times as is needed to expel the air from the plastic feedstock. The introduced gas from the lowest section of pipe could be directed to the next section and so on until it leaves the highest section and is directed to the flare. An oxygen sensor could be used on the final / lowest section of pipe to ensure there is no oxygen left before dumping the plastic into the retort.

One advantage of this method over an auger screw feeder is simplicity. This method would allow unheated plastic to be shuffled down the pipe, section after section using only a few valves. The plastic would need to fall freely of course so maybe only dense plastics would be suitable.

I have no idea how well it would work. The idea mentioned some time back about casting cylinders of plastic to match the size of the feed tube is a very good one I think, you could melt down any density of plastic.

Col

Leave a comment:

-

Originally posted by rozier56 View PostHi folks, here is plant no3.I have changed the distillation column to a 40lt size[300MM X600MM].My retort is 300lt in volume full.I ran the plant at 330*c and could only produce 2lt/hr of diesel as you see attached.Looks like good product.At no stage was my condenser over heated as i have this temp monitored. This rate is far less than when i was using a small distillation column[4,5,LT].Any bright ideas about this?Babataku is right. Also, your condenser should not be horizontal, but face down. See an illustration of the basic fractionation column from the Petroleum Handbook.Originally posted by Babataku View Posthi there,

1. 330 deg celc is way too low, consider increasing temp to 400 - 420 deg celc for maximum production results.

2. It seems that you are not insulating your lead / flange and since your exit pipe is not directly on the flange / lid, that uninsulated spot will act as a reflux zone and your actual reflux even if you heat it or insulate it will not be effective. consider insulating it.

Hope it makes sense

Leave a comment:

-

The reasons for holding the diesel reservoir at 80-120*C is twofold. It will force any lighter fractions present to boil off and be captured downstream. The temperature determines the force at which these more volatile components will evaporate. A higher temp will drive off more, pushing it down to the petrol condenser.Originally posted by rozier56 View PostHi folks, note the temp of 330*c was measured on top of the reflux chamber on my new plant.plus i notice from your back reference to others that mention is made that the diesel was seperated at 80-120*c.My condenser temp at exit is almost 20*C,is that too low, must i be cooling to higher temp?This means that i am going from 330*c on my reflux down to 20*c within 1.5 meters of condenser,maybe i need to cool slower?

The other benefit is to create more gases for a burner. Recently 120*C in my diesel reservoir yielded good, record quantities of burnable gas as well as a number of liters of petrol was trapped in the petrol condenser.

Just what target temperature you would choose depends on what outcome you are aiming for. I tend to want to evaporate the volatiles from my diesel to improve the stability and raise the boiling point. Another consideration would be specific gravity of the product.

Leave a comment:

-

Usually if I want to change the hair style I will buy the cheap hair wigs at the online shop so that it will neither cost me a lot and I can reach the goal of change my hair style easily. And just a week before I bought one buy wigs and it makes me look better.Last edited by MargorieLonn; 03-31-2014, 10:16 AM.

Leave a comment:

-

production rates

Hi folks, note the temp of 330*c was measured on top of the reflux chamber on my new plant.plus i notice from your back reference to others that mention is made that the diesel was seperated at 80-120*c.My condenser temp at exit is almost 20*C,is that too low, must i be cooling to higher temp?This means that i am going from 330*c on my reflux down to 20*c within 1.5 meters of condenser,maybe i need to cool slower?

Leave a comment:

-

Excess Gas Burner Ideas

Hi All,

Any ideas on a good burner design for excess gasses? i am working on a 400ltr retort system and i am looking for a burner design that can handle the volume of the excess gasses and if possible a design for an enclosed burner system where the flame is not visible.

My last outfits were small and the excess gasses were just burned off a regular 1/2 inch pipe with flames visible...this time i want the flames to be contained in a pipe or in some way, not visible... Any ideas??

Leave a comment:

-

Have a look at my first attempt in May 2012Originally posted by NickTech View PostThank you for your answer.

According to you, how I should modify my system to get better results?

Only insulation around the retort and termocuples to control the process is enough?

Thanks

Nick

There is an old propane 9kg cylinder inside the drum. In this system there is heat all around the 9kg cylinder. The vertical pipe to the right is the flue-stack. The heat is from burning timber.

I realized I was "blind" without thermocouples monitoring the process!

Insulation should go around the outer drum to minimize heat loss. This will give the heat less opportunity to wastefully bleed away to atmosphere.

I suspect your heat source will need upgrading too but fix one thing at a time. Step by step.

Leave a comment:

-

To clarify my figures are:Originally posted by rozier56 View PostHi excalibur,when you were making approx 30lt/hr, what sort of reflux temps were you using? Babataku mentions 400-450*c.What is your opinion?

Retort: 380*C - 425*C

Reflux: 350*C

Diesel vessel: 80*C - 120*C

These temperatures are for runs with WMO. My plastic feedstocks are yet to be trialed. Note, my retort sensor is in the top of the vessel, not actually in the liquid. It gets the heat from the rising vapor. This may account for the fact that I can get quite good gas/condensate flow even at 380*C or possibly it's because the WMO is more lively than plastic feedstocks. I'd expect to have to revise the reflux temperature downward for plastic feedstocks. Please view the figures as a guide to be tweaked to the requirement of your setup, feedstock and conditions.

The upper condenser/water cooled heat exchanger. Does this have some incline as it runs away, toward the diesel reservoir vessel? I suggest at least a couple of degrees fall.

Leave a comment:

-

Thank you for your answer.Originally posted by Excalibur View PostThe answer depends on how big the retort is, how much feedstock inside, how much heat is being applied and how big the heat losses are. If I could see the unit, I'd have a better idea. How about photos?

From memory, all my prototypes took at least an hour. Many would underestimate how much heat is required. Be sure to use thermocouples to monitor progress. A bubbler is also an indicator of gas flow though early bubbling is likely to be water boiling off, followed by a period of calm before gas flow creates bubbles. Soon after will come the first fuel drips probably around mid 300* -400*C.

I suggest to dismantle the unit and check for clogging with solid plastic. If all is well, then resume with thermocouples and bubbler. A sight glass/viewing port is also a good way of understanding what is going on inside.

Edit: I saw your pic after posting. I think there is not enough heat with that gas ring. Also there appears to be no insulation. The plastic bottle as a catch can will melt because the vapors will be exiting at 400*C with almost nothing to cool it before it runs out of the pipe.

Everyone's got to start somewhere. Even my first attempt I didn't make anything, then the second attempt I got 10-15liters of wax. Some upgrades will be necessary before you can produce fuel.

According to you, how I should modify my system to get better results?

Only insulation around the retort and termocuples to control the process is enough?

Thanks

Nick

Leave a comment:

-

Hi excalibur,when you were making approx 30lt/hr, what sort of reflux temps were you using? Babataku mentions 400-450*c.What is your opinion?

Leave a comment:

-

increase temp

hi there,Originally posted by rozier56 View PostHi folks, here is plant no3.I have changed the distillation column to a 40lt size[300MM X600MM].My retort is 300lt in volume full.I ran the plant at 330*c and could only produce 2lt/hr of diesel as you see attached.Looks like good product.At no stage was my condenser over heated as i have this temp monitored. This rate is far less than when i was using a small distillation column[4,5,LT].Any bright ideas about this?

1. 330 deg celc is way too low, consider increasing temp to 400 - 420 deg celc for maximum production results.

2. It seems that you are not insulating your lead / flange and since your exit pipe is not directly on the flange / lid, that uninsulated spot will act as a reflux zone and your actual reflux even if you heat it or insulate it will not be effective. consider insulating it.

Hope it makes senseLast edited by Babataku; 03-27-2014, 06:48 PM.

Leave a comment:

Leave a comment: