Originally posted by Excalibur

View Post

If we had a pipe off to the side of the retort (to get away from the splashing etc) with a steel ball floating in it, and made the pipe of borosilicate or some other non-metallic material, we could use the floating steel ball to actuate a series of magnetic relays which would then tell us the oil level - like this...

Uhz 517c11 High Temperature Liquid Water Level Sensor With Transmitter From Water Meter Manufacturer Max 450 Centigrade 150lb - Buy Liquid Water Level Sensor,Water Meter Manufacturer,Pool Water Level Sensor Product on Alibaba.com

Udm-10 With High Quality Liquid Level Measurement Sensors - Buy High Quality Liquid Level Measurement Sensors,Fuel Level Float,Plastic Water Level Indicator Product on Alibaba.com

Liquid Level Sensor - Buy Liquid Level Sensor Product on Alibaba.com

The level readings from all three could be assisted by putting baffles made from perforated sheet around the level sensor. You could also program the controls for the feed pump to wait for the sensor to stabilise over a period of a few seconds before actuating the pump, just to be sure.

Apart from the colour and sediment, what was the quality of the product produced by flash-boiling? Still ok?

Yes, matching feed to output is cumbersome. While I haven't measured, the off gases probably amount to a few percent. Yes, if feed matched output and the heat input could be stable, that would be magic. In practice it hasn't been so easy. Originally, I thought I'd be able to crank the heat up high, then apply the feed till a state of equilibrium was reached. One upgrade I'm planning is to use a needle valve instead of ball valve for improved flow control of feed. A ball valve is on or off with little adjustability in between.

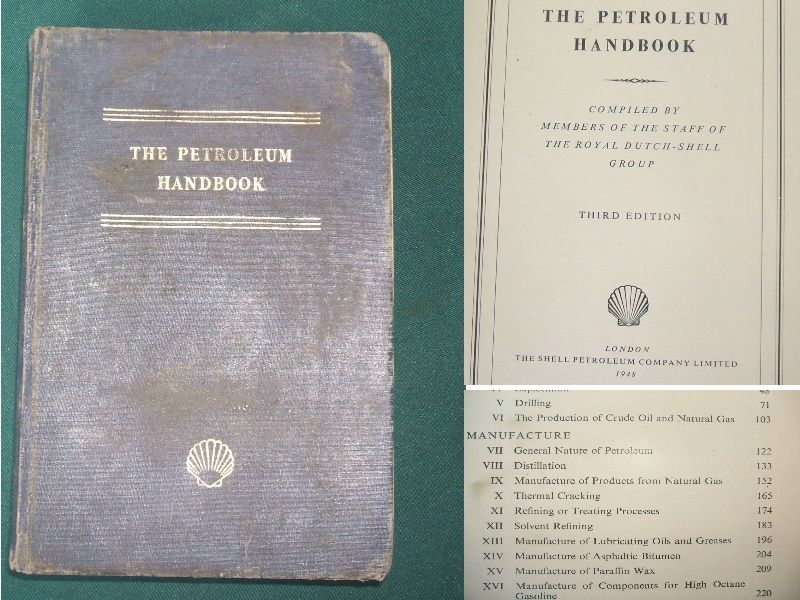

Yes, matching feed to output is cumbersome. While I haven't measured, the off gases probably amount to a few percent. Yes, if feed matched output and the heat input could be stable, that would be magic. In practice it hasn't been so easy. Originally, I thought I'd be able to crank the heat up high, then apply the feed till a state of equilibrium was reached. One upgrade I'm planning is to use a needle valve instead of ball valve for improved flow control of feed. A ball valve is on or off with little adjustability in between. The book is a bit battered but perfectly legible.

The book is a bit battered but perfectly legible.

Leave a comment: