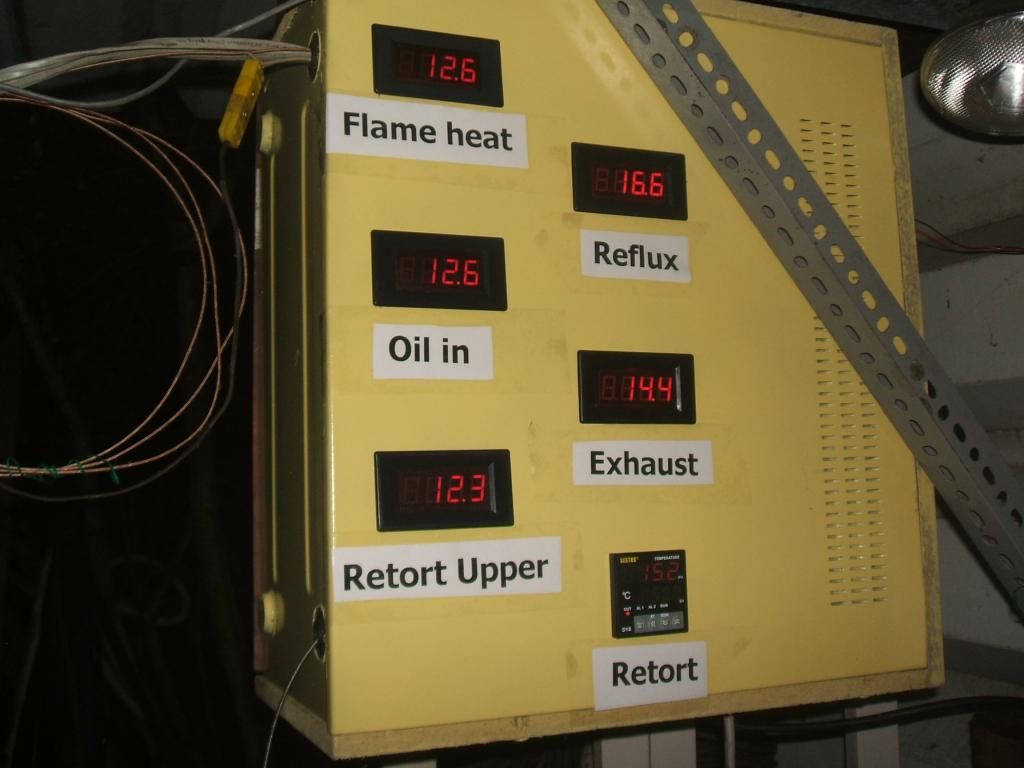

Heating and cooling cycle

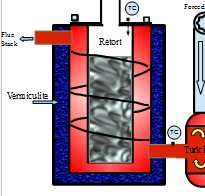

Heating and cooling cycle will be facing thermal fatigue and so one has to be careful while selecting the thickness of plate for reactor . One should consider thermal fatigue property while designing batch type reactor

Originally posted by wheels

View Post

Comment