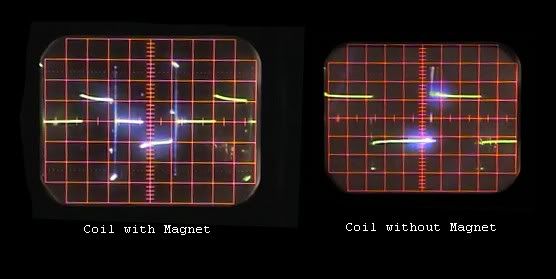

Hi Geotron, I'm distracted again now. I was completely engrossed in my experimenting.  Umm actually I'm finding that i can only get 4.6 Khz or so with the newer circuit. When I originally tried the CFL directly from the ignition coil I used a circuit the same but it was a temporary one and I can't remember the timing cap value, anyway this circuit is different but only in the frequency/PW. I am trying so much stuff I am getting confused, this is so much fun.

Umm actually I'm finding that i can only get 4.6 Khz or so with the newer circuit. When I originally tried the CFL directly from the ignition coil I used a circuit the same but it was a temporary one and I can't remember the timing cap value, anyway this circuit is different but only in the frequency/PW. I am trying so much stuff I am getting confused, this is so much fun.

The way I have the TC secondary connected to the primary and ground and the ignition coil negative is also grounded, which is a must if driving the HV open ended. Anyway I think it makes it so that the CFL's are forced to light, i'm not sure how it does not force the voltage to go directly from the TC primary then up the tower wire just like a wire connection. Not sure it is such a good idea. It works though.

Not sure it is such a good idea. It works though.

The volcano setup is a capcitive spark gap, I can use it in parallel with the HV or in series and if I adjust the gap it give's a voltage limit.

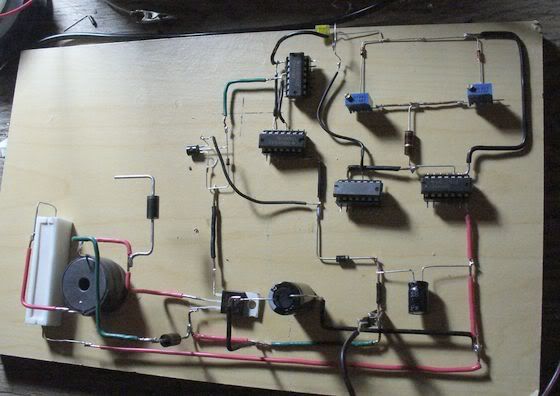

I'm running the Ignition HV through the thick TC primary then the primary wraped on the stick in the photo below, I can get thousands of volts into a microwave cap from the small center tapped coil on the tube, but the microwave cap has a resister in it too, so it bleeds away fast. Damn resistors To make the gap spark I just disconnect the Tower secondary negative from the primary and ground the tower negative then the primary grounds through the spark gap. I need a 1 uf or so HV cap for the spark gap to work well I think.

To make the gap spark I just disconnect the Tower secondary negative from the primary and ground the tower negative then the primary grounds through the spark gap. I need a 1 uf or so HV cap for the spark gap to work well I think.

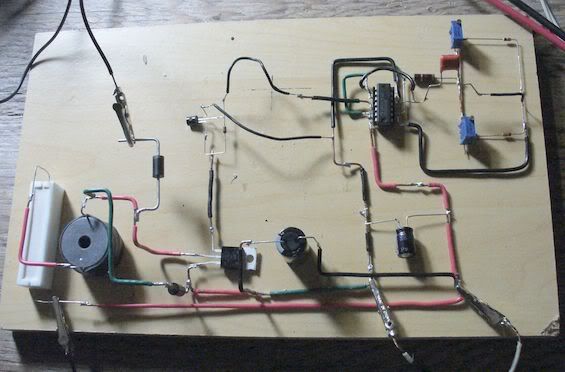

There is a lot of unecessary stuff in the picture, for experimenting, I have gone to a spiral primary now for the TC and I'm playing with a spark gap now.

http://wv0v9q.bay.livefilestore.com/...001.JPG?psid=1

My bench is an incredible mess but everytime I try to clean it up I end up experimenting some more because I get more idea's.

I didn't remove the resistor just wired the setup different. It's handy to know about the 2500 volts I think I am getting about the same voltage I thought it would be more but I guess the peaks are high and the average is less.

The plate behind the tower coil is just a radiant energy collector plate "P", it is connected to a cap to collect radiations or emanations. The bowl is just a virtual ground/ connector bus, whichever experiment I'm doing.

I cant seem to get the CFL's to light when I use the spark gap, but neons light wirelessly a lot better. Now I want to try wireless an one wire transmission, I need to wind another tower coil, and also a pair of spiral coils that fill the plastic plates they will be transmission experiment coils.

NIKOLA TESLA - Google Patents

I have an idea for an arrangement to pulse the 2 turn primary (around the pancake coils) kind of directly from my circuit with no spark gap so it is like an exciter for transmission experiment's. But I will have to make my own flyback with a fair bit less peak voltage than the Ignition coil. The problem is a thick primary has little self inductance so I will need to introduce more self inductance to the circuit, Tesla used large self induction coils which charged on the closing of the circuit and discharged into a cap or caps which disharged through the thick 1 or 2 turn primary suddenly. If I reduce my voltage I can find caps easier.

I think the voltage is too high to recover any usefull amount without a lot of HV caps.

Anyway now I had a sleep I can get back to it. For another 48 hours.

Cheers

Umm actually I'm finding that i can only get 4.6 Khz or so with the newer circuit. When I originally tried the CFL directly from the ignition coil I used a circuit the same but it was a temporary one and I can't remember the timing cap value, anyway this circuit is different but only in the frequency/PW. I am trying so much stuff I am getting confused, this is so much fun.

Umm actually I'm finding that i can only get 4.6 Khz or so with the newer circuit. When I originally tried the CFL directly from the ignition coil I used a circuit the same but it was a temporary one and I can't remember the timing cap value, anyway this circuit is different but only in the frequency/PW. I am trying so much stuff I am getting confused, this is so much fun.

The way I have the TC secondary connected to the primary and ground and the ignition coil negative is also grounded, which is a must if driving the HV open ended. Anyway I think it makes it so that the CFL's are forced to light, i'm not sure how it does not force the voltage to go directly from the TC primary then up the tower wire just like a wire connection.

Not sure it is such a good idea. It works though.

Not sure it is such a good idea. It works though.The volcano setup is a capcitive spark gap, I can use it in parallel with the HV or in series and if I adjust the gap it give's a voltage limit.

I'm running the Ignition HV through the thick TC primary then the primary wraped on the stick in the photo below, I can get thousands of volts into a microwave cap from the small center tapped coil on the tube, but the microwave cap has a resister in it too, so it bleeds away fast. Damn resistors

To make the gap spark I just disconnect the Tower secondary negative from the primary and ground the tower negative then the primary grounds through the spark gap. I need a 1 uf or so HV cap for the spark gap to work well I think.

To make the gap spark I just disconnect the Tower secondary negative from the primary and ground the tower negative then the primary grounds through the spark gap. I need a 1 uf or so HV cap for the spark gap to work well I think.There is a lot of unecessary stuff in the picture, for experimenting, I have gone to a spiral primary now for the TC and I'm playing with a spark gap now.

http://wv0v9q.bay.livefilestore.com/...001.JPG?psid=1

My bench is an incredible mess but everytime I try to clean it up I end up experimenting some more because I get more idea's.

I didn't remove the resistor just wired the setup different. It's handy to know about the 2500 volts I think I am getting about the same voltage I thought it would be more but I guess the peaks are high and the average is less.

The plate behind the tower coil is just a radiant energy collector plate "P", it is connected to a cap to collect radiations or emanations. The bowl is just a virtual ground/ connector bus, whichever experiment I'm doing.

I cant seem to get the CFL's to light when I use the spark gap, but neons light wirelessly a lot better. Now I want to try wireless an one wire transmission, I need to wind another tower coil, and also a pair of spiral coils that fill the plastic plates they will be transmission experiment coils.

NIKOLA TESLA - Google Patents

I have an idea for an arrangement to pulse the 2 turn primary (around the pancake coils) kind of directly from my circuit with no spark gap so it is like an exciter for transmission experiment's. But I will have to make my own flyback with a fair bit less peak voltage than the Ignition coil. The problem is a thick primary has little self inductance so I will need to introduce more self inductance to the circuit, Tesla used large self induction coils which charged on the closing of the circuit and discharged into a cap or caps which disharged through the thick 1 or 2 turn primary suddenly. If I reduce my voltage I can find caps easier.

I think the voltage is too high to recover any usefull amount without a lot of HV caps.

Anyway now I had a sleep I can get back to it. For another 48 hours.

Cheers

Comment