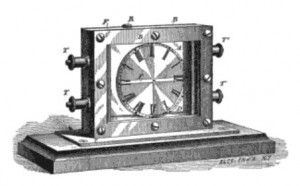

To carry out this invention I employ a motor embodying the principle of construction of a motor described and claimed in an application filed by me January 8, 1889, No. 295,745, to the extent that both the armature and field receive their magnetism from a single energizing-coil or a plurality of coils acting as one.

Tesla Patent 424,036 - Electro-Magnetic Motor

Tesla Patent 424,036 - Electro-Magnetic Motor

+

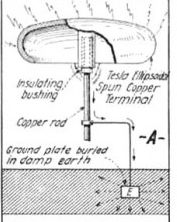

In accordance with the invention, provision is made for enveloping the patient in a high potential and, in certain instances, a high frequency electric field, and for applying to the patient, while so enveloped in the electric field, radiations and emanations having therapeutic value.

Thomas H. Moray: Transmutation of Low Grade Ores by High Energy Bombardment

Thomas H. Moray: Transmutation of Low Grade Ores by High Energy Bombardment

Wesley Gary's Magnetic Motor

In order to secure this reversal or loss of polarity in the armature without having it actually touch the magnet it has been hitherto considered necessary that the armature should be carried into and out of the magnetic field or field of attraction of the magnet; or else from the field of one pole into that of the other. This operation required the movement of the armature a long distance, necessitating the expenditure of a large amount of power, limited the frequency of the polar changes, and precluded the full utilization of the magnetic influence.

My invention derives its value mainly from the fact that I do not carry the armature out of the magnetic field, but operate it wholly therein, and secure by a very slight movement the same or better results than those secured in existing machines.

My invention derives its value mainly from the fact that I do not carry the armature out of the magnetic field, but operate it wholly therein, and secure by a very slight movement the same or better results than those secured in existing machines.

continuing :

Magnetism - Howard Johnson - Roy Davis and Rawls - Bloch Wall - Magnetic Vortex - YouTube

http://en.wikipedia.org/wiki/Domain_wall_(magnetism)

Magnetism[edit]

In magnetism, a domain wall is an interface separating magnetic domains. It is a transition between different magnetic moments and usually undergoes an angular displacement of 90į or 180į. Domain wall is a gradual reorientation of individual moments across a finite distance. The domain wall thickness depends on the anisotropy of the material, but on average spans across around 100Ė150 atoms.

The energy of a domain wall is simply the difference between the magnetic moments before and after the domain wall was created. This value is usually expressed as energy per unit wall area.

The width of the domain wall varies due to the two opposing energies that create it: the magnetocrystalline anisotropy energy and the exchange energy (), both of which tend to be as low as possible so as to be in a more favorable energetic state. The anisotropy energy is lowest when the individual magnetic moments are aligned with the crystal lattice axes thus reducing the width of the domain wall. Conversely, the exchange energy is reduced when the magnetic moments are aligned parallel to each other and thus makes the wall thicker, due to the repulsion between them (where anti-parallel alignment would bring them closer, working to reduce the wall thickness). In the end an equilibrium is reached between the two and the domain wall's width is set as such.

In magnetism, a domain wall is an interface separating magnetic domains. It is a transition between different magnetic moments and usually undergoes an angular displacement of 90į or 180į. Domain wall is a gradual reorientation of individual moments across a finite distance. The domain wall thickness depends on the anisotropy of the material, but on average spans across around 100Ė150 atoms.

The energy of a domain wall is simply the difference between the magnetic moments before and after the domain wall was created. This value is usually expressed as energy per unit wall area.

The width of the domain wall varies due to the two opposing energies that create it: the magnetocrystalline anisotropy energy and the exchange energy (), both of which tend to be as low as possible so as to be in a more favorable energetic state. The anisotropy energy is lowest when the individual magnetic moments are aligned with the crystal lattice axes thus reducing the width of the domain wall. Conversely, the exchange energy is reduced when the magnetic moments are aligned parallel to each other and thus makes the wall thicker, due to the repulsion between them (where anti-parallel alignment would bring them closer, working to reduce the wall thickness). In the end an equilibrium is reached between the two and the domain wall's width is set as such.

from : http://www.energeticforum.com/renewa...iguera-22.html

Originally posted by Michelinho

View Post

Magnetocrystalline anisotropy - Wikipedia, the free encyclopedia

Practical relevance[edit]

Magnetocrystalline anisotropy has a great influence on industrial uses of ferromagnetic materials. Materials with high magnetic anisotropy usually have high coercivity; that is they are hard to demagnetize. These are called "hard" ferromagnetic materials, and are used to make permanent magnets. For example, the high anisotropy of rare earth metals is mainly responsible for the strength of rare earth magnets. During manufacture of magnets, a powerful magnetic field aligns the microcrystalline grains of the metal so their "easy" axes of magnetization all point in the same direction, freezing a strong magnetic field into the material.

On the other hand, materials with low magnetic anisotropy usually have low coercivity, their magnetization is easy to change. These are called "soft" ferromagnets, and are used to make magnetic cores for transformers and inductors. The small energy required to turn the direction of magnetization minimizes core losses, energy dissipated in the transformer core when the alternating current changes direction.

Practical relevance[edit]

Magnetocrystalline anisotropy has a great influence on industrial uses of ferromagnetic materials. Materials with high magnetic anisotropy usually have high coercivity; that is they are hard to demagnetize. These are called "hard" ferromagnetic materials, and are used to make permanent magnets. For example, the high anisotropy of rare earth metals is mainly responsible for the strength of rare earth magnets. During manufacture of magnets, a powerful magnetic field aligns the microcrystalline grains of the metal so their "easy" axes of magnetization all point in the same direction, freezing a strong magnetic field into the material.

On the other hand, materials with low magnetic anisotropy usually have low coercivity, their magnetization is easy to change. These are called "soft" ferromagnets, and are used to make magnetic cores for transformers and inductors. The small energy required to turn the direction of magnetization minimizes core losses, energy dissipated in the transformer core when the alternating current changes direction.

Soft iron[edit]

"Soft" (annealed) iron is used in magnetic assemblies, electromagnets and in some electric motors; and it can create a concentrated field that is as much as 50,000 times more intense than an air core.[2]

Iron is desirable to make magnetic cores, as it can withstand high levels of magnetic field without saturating (up to 2.16 teslas at ambient temperature.[3])

It is also used because, unlike "hard" iron, it does not remain magnetised when the field is removed, which is often important in applications where the magnetic field is required to be repeatedly switched.

Unfortunately, due to the electrical conductivity of the metal, at AC frequencies a bulk block or rod of soft iron can often suffer from large eddy currents circulating within it that waste energy and cause undesirable heating of the iron.

Magnetic core - Wikipedia, the free encyclopedia

"Soft" (annealed) iron is used in magnetic assemblies, electromagnets and in some electric motors; and it can create a concentrated field that is as much as 50,000 times more intense than an air core.[2]

Iron is desirable to make magnetic cores, as it can withstand high levels of magnetic field without saturating (up to 2.16 teslas at ambient temperature.[3])

It is also used because, unlike "hard" iron, it does not remain magnetised when the field is removed, which is often important in applications where the magnetic field is required to be repeatedly switched.

Unfortunately, due to the electrical conductivity of the metal, at AC frequencies a bulk block or rod of soft iron can often suffer from large eddy currents circulating within it that waste energy and cause undesirable heating of the iron.

Magnetic core - Wikipedia, the free encyclopedia

....

....

.png)

)

)

Comment