test connectors

@Cornboy,

Where did you locate the k1xo2 k1x04 and k1x06 terminal tester strips. I have not been able to find any with the long leads on them in my google searchs.

Cheers,

Garry

@Cornboy,

Where did you locate the k1xo2 k1x04 and k1x06 terminal tester strips. I have not been able to find any with the long leads on them in my google searchs.

Cheers,

Garry

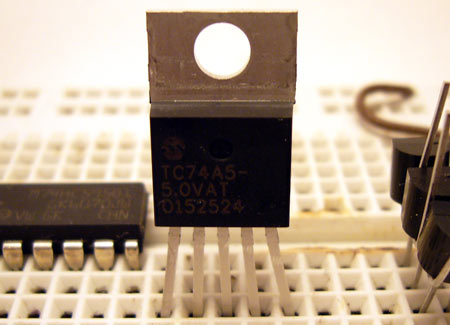

. I intend to suggest a 5V only system. Sparkfun use TMP102 chip from TI. TI offers very same device TMP101 for 5V. But I found no breakout PCB. Is any other sensor breakout with 5V available?

. I intend to suggest a 5V only system. Sparkfun use TMP102 chip from TI. TI offers very same device TMP101 for 5V. But I found no breakout PCB. Is any other sensor breakout with 5V available?

$6.95

$6.95 $1.95

$1.95 this week we got a chance to look into using the IR sensor from sparkfun

this week we got a chance to look into using the IR sensor from sparkfun

, i thought i may have cooked it so i replaced it with another, but measured it first and output was 5v, when installed output is 11v

, i thought i may have cooked it so i replaced it with another, but measured it first and output was 5v, when installed output is 11v

Comment