@ Kogs

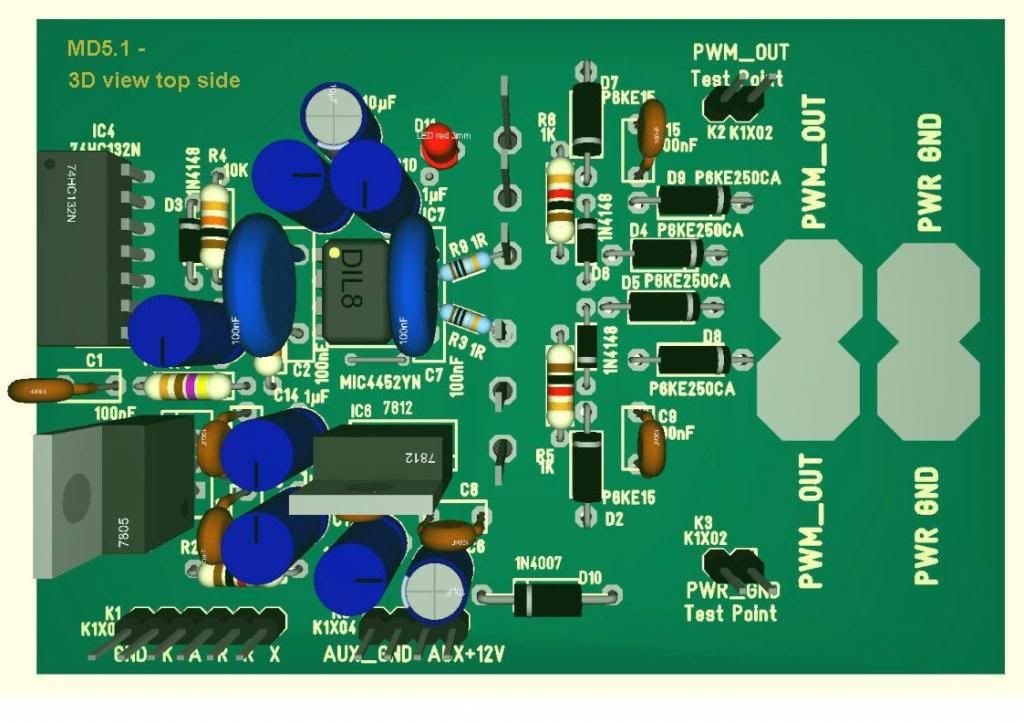

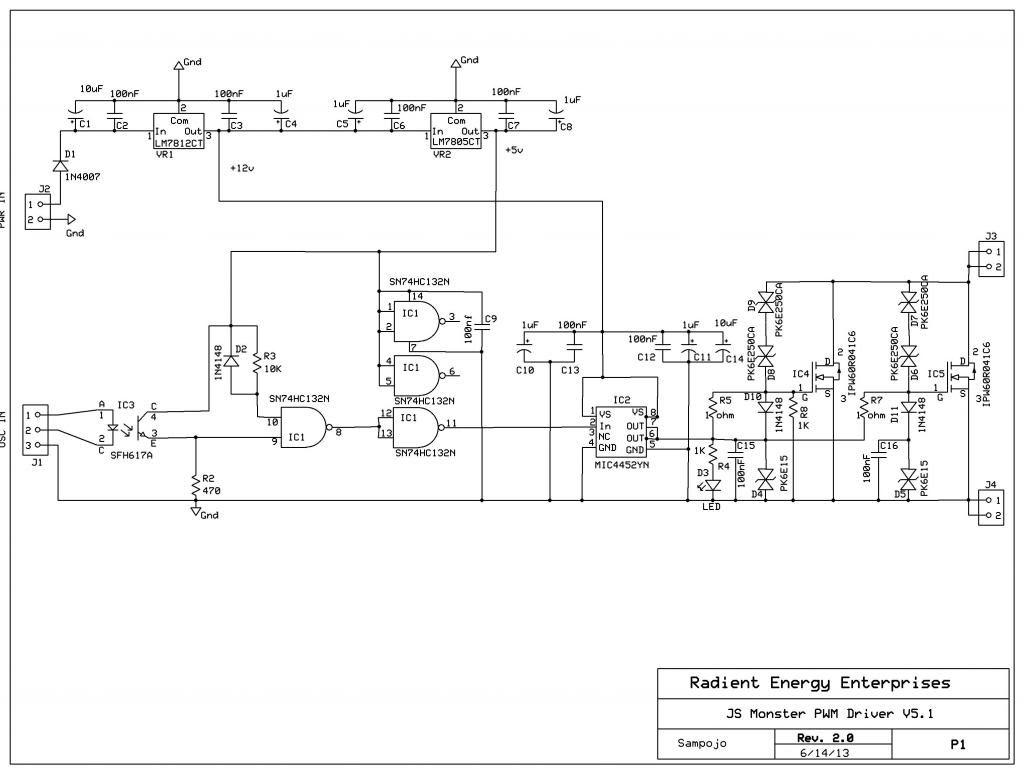

JohnStone sent me his file some time ago but I need to find it in my computer. Here is what I can find at the moment, its a start.

https://www.dropbox.com/s/4dip28wcge...0V5.1%20.T3001

Dana

JohnStone sent me his file some time ago but I need to find it in my computer. Here is what I can find at the moment, its a start.

https://www.dropbox.com/s/4dip28wcge...0V5.1%20.T3001

Dana

Comment