Originally posted by Turion

View Post

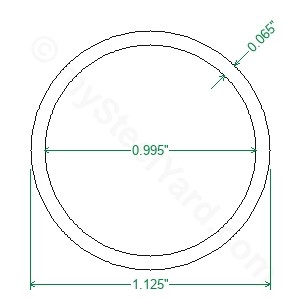

resistant. This is the thickness I use and here are the benefits.

$5 per foot

https://mysteelyard.com/product_info...ducts_id=11274

negligible as far as space is concerned. Once in all side projecting

fields are pushed out front where we want it. There are some examples

on youtube where magnet rotors having upperwards of 20 have shields

and magnets4less only has a cheap refrigerator magnet junk pile.

Once pressed in you can and should leave a few thousandths sticking

out then the outer surface of the shield can be wildly ground rough tp

a point of distortion to receive a greater epoxy contact and holding

power. Much better. What is even more important for your application

is that the magnets all having shields would increase the holding power

probably 50%

The most important use is when you want magnets close together so

their fields are out front and not over lapping. It is a harder task that

you may be tempted to stay away from even though it might produce

double the output.

here is what I know, when bring a block of steel near my shield-less

magnets at the bloch wall they spin around and snap right on at a

distance of 1/4".

With shield the same block of steel has no effect and does not respond.

No magnetic pull sitting right on the bloch wall, nothing, it's all out

front and man is it ever strong where it is suppose to be.

the principles office is the scary place

the principles office is the scary place

I think you standing in front of that

I think you standing in front of that

Comment