Understand how a Theremin works (the electric musical instrument)

and you will see how to change capacitance to change resonant frequency

Make a parametric oscillator that changes it's frequency.

Announcement

Collapse

No announcement yet.

Peter, whatever happened with Eric P. Dollard?

Collapse

This topic is closed.

X

This is a sticky topic.

X

X

-

That's a good thought, but I'm pretty sure the rotor is getting very hot due to eddy currents and I'm pretty sure we aren't losing any power. In an effort to fix the rotor stability problems, we welded the plates together. Not so sure that was a good idea.

Regardless, I'm 90% convinced that the rotor is loading the motor because of eddy currents, and whether it loads due to the extra power generated will be impossible to tell until we eliminate them. We'll get there.Last edited by LtBolo; 06-07-2010, 02:37 AM.

Leave a comment:

-

Just a brief thought. Maybe you have accidentally hit the spot where energy "disappears". It can only be assumed that this would coincide with heat but might not be measurable, if you compare it to energy creation as in negative energy entering the system which is supposedly always cooling the components.

So maybe there is a sweetspot in your device that would in fact create energy and you are just tuned to the "bitterspot" right now.

All just speculation, and maybe i am just wrong. If this was any kind of other motor without inductance variation, it could certainly just be attributed to friction.

You will improve this eventually.

Big respect to your hard experimental work, many people appreciate it.

Keep it up! Last edited by Xenomorph; 06-07-2010, 12:53 AM.

Last edited by Xenomorph; 06-07-2010, 12:53 AM.

Leave a comment:

-

Strange. In trying to get the mechanical stable, we moved the rotor to the inside of the 'C'. This reduced the inductance, but still worked. It also appeared to saturate the core and limit the output. So we added about 200 more turns and increased the inductance to something higher than it was before. Now the output barely resonates, only showing about a volt or so at resonance.

Weird thing is that it still gets loud and the motor definitely loads...increases current by about 1.5amps....and...the rotor gets smoking hot, although nothing is touching now. It appears that there are eddy currents in the rotor that are causing the loading.

So, parameter change will induce power and Lenz still lives. The Russian paper used aluminum for the rotor. Guess I know why now.

Jury is still out.

Leave a comment:

-

Once I wrapped my head around synchronous parameter change, it started to become pretty obvious that many of the devices that people have been playing with for decades could potentially work. The problem is that until you evaluate the expected power gain against the power loss, you don't know what you are looking for.

I think the other issue than many face is that according to Dollard, you can either add or remove energy dependent on phase. I think that many of the solid state approaches are doing it exactly backwards. It would be very interesting to do a thermal analysis in a resonant saturated core setup. I would speculate that there is some energy missing in many cases.

Our device sits on the edge of working/not working...we don't have quite enough inductance change...probably could use another 200 turns on the coil. From our experience, when the parameters aren't quite right, you get nothing. When you get them right, however, hold on to your hat!

We are still struggling to evaluate input to output power ratio. When the current gets very high, the magnetic stresses get very high, and we keep having mechanical problems. When you are grinding metal off of the core, it becomes very difficult to evaluate whether you are getting more out than in. We are making another mechanical change now, and hopefully that will be enough. If not, we may have to scrap this one and build it right. I really didn't want to spend the money and time until we were convinced this isn't simply a 1:1 generator.

Leave a comment:

-

So technically a reluctance motor or a Lindemann motor can do the job. Only is the rotor driven by an external motor.

Leave a comment:

-

It is just a piece of transformer core material, same as the rest of it...actually it was cut from the same transformer. We attached it to an aluminum cylinder to mount to the motor.Originally posted by wonderful View PostI have a question: what kind of metal you use for the rotor?

Leave a comment:

-

Rotor

Very good LtBolo,

I have a question: what kind of metal you use for the rotor?

Thanks

Luco

Leave a comment:

-

Variable frequency drive, running at about 65-66Hz. We are limited to about 71Hz max speed by the drive and motor, so we picked caps to be near the top of the range.Originally posted by broli View PostI'm curious, is this an AC motor? If so at what frequency was it running?

We are rebuilding now to eliminate the lateral force on the motor, and then will determine whether this is simply loading on the motor with no free power...or free power. Either way, we have conclusively proven that you can generate power via synchronous parameter change...pretty amazing.

Not sure how we'll regulate. The Russian paper talked about using non-linear loads like incandescent bulbs, so we may go that route for power evaluation. Once we have proven that the power isn't simply from the motor, we'll look at an electronic closed loop control.

Leave a comment:

-

Thanks, this is the spirit I like. Instead of wasting meaningless words the truth should be uncovered through experimentation and an open mind.Originally posted by EgmQCi was "maybe" a bit too fast in my speculation so ill give it a try , ill do your experiment this week and ill post result, good or bad, i have a decent lab and a bit of time to work on it but ill keep it the way it should be , all the calculation that fit the "normal way" and ill compare the result against it.

Best Regards,

EgmQC

Good work LtBolo. I'm curious, is this an AC motor? If so at what frequency was it running? The point I'm getting at is that closing the loop might be a simple task if the motor is running at the same frequency as the output. That is if the output is regulated first.Originally posted by LtBoloWell, we ran it. It works.

There are some caveats, however. As predicted by the formula, the output current increases geometrically, which means the magnetic field is also increasing geometrically. Unfortunately, the high magnetic field causes our motor shaft to pull in, which causes our 030" gap to close loudly...metal on metal. We do see the motor current increase a bit due to the lateral shaft force, but we don't think that the increase in motor load matches the amount of output. Unfortunately, until we can get a better mechanical arrangement, it will be impossible to verify that there isn't an equivalent load on the motor. Of course, once the core pieces start hitting each other, the motor draws far more current still...and it gets loud.

That said, it works exactly as predicted. We managed to get it stable at about 100VAC for a while. At 100VAC, we measured about 1.8 watts of dissipation across a 1.5 ohm resistor, as well as about another watt in one of our caps that was breaking down. That cap was a mistake, but it worked out well...it became the non-linear load that kept it all stable. This agreed very well with the predicted 2.5 to 3 watts of excess power at 1 amp.

Note the scopeshot: This is the output going critical. I pulled the wire to shut it down. Note that it hit 381vpp before I pulled the plug. Obviously it showed no signs of slowing down, and the current was well above 1 amp at that point, but we had no way of measuring.

I think this is the real deal...Last edited by broli; 06-05-2010, 08:51 AM.

Leave a comment:

-

LtBolo,

Congratulations, it looks like "your are in business" like Don Smith tend to say.

Watch all his videos and you will see the same exact picture of scope shots.

Now you need a regulator to drop to zero above exact voltage or current. Try transient diodes they are rated for 1500W and any voltage you choose.Then try to maximalize output by two methods: positive feedback (self-sustaining device) and changing frequency. Your scope should looks like many exact trumpets occuring one after another. Or you can rectify output which would then look like TPU - DC with a hash (pulsating). You will know exactly why it is a hash there - system need small period of time to obtain maximum efficiency (max voltage amplitude on scope shot) then drop then again rising.

Keep in mind that I'm telling this all from theory, never made such device, really, but I know that such devices exists.

Leave a comment:

-

i was "maybe" a bit too fast in my speculation so ill give it a try , ill do your experiment this week and ill post result, good or bad, i have a decent lab and a bit of time to work on it but ill keep it the way it should be , all the calculation that fit the "normal way" and ill compare the result against it.Originally posted by broli View PostSomeone posted this earlier:

First It was a presentation I made a while ago. Second your capacitance "analogy" is wrong too it seems like all you did is use the input energy to get a desired voltage which would satisfy conservation of energy. But that's like saying 1+1 = 3 and using that same equation as proof.

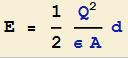

It's best to see energy as charge density and distance between plates. This makes the equation look like this:

So now you can easily see what happens when you change the parameters. If you increase the area the charge will still remain it will just spread out over the new area. But our energy drops in equal proportion. But if you increase the distance the energy is increased in equal proportion. But since the plates are oppositely charged this increase in distance needs mechanical energy. It's only a question of experimentation whether more electric energy is gained than lost mechanically.

Capacitors are equivalent to springs, and parametric change is equal to changing the stiffness of the spring at the right moment.

Now to get back to inductors as you are comparing apples with oranges. Inductors act like mass. The more mass the more they resist a force which wants to get them moving. An oscillating mass attached to a spring is a suitable example. A compressed spring wants to push a mass, if this mass is small the spring decompresses fast, but just when the spring is fully uncompressed the mass is "magically" increased. In our inductor this is done by increasing the core permeability, since it was fully saturated at start the current rises fast (ie the velocity in our spring/mass) but at maximum current the magnet is removed mechanically and forced saturation is gone. You then collapse this field which is now coil + core and gain the extra energy.

Mechanically this is "impossible" to do as it would mean changing the mass of an object while its speed remains unaffected. But in our inductor there's no reason why the current will be affected.

Best Regards,

EgmQC

Leave a comment:

-

LtBolo,

Great work!! Not sure if you've seen these series of videos YouTube - Part 1 of 6: Eric Dollard Tesla Longitudinal wave Energy SBARC Ham Radio with Chris Carson by Eric Dollard. He speaks about how the N Machine by Bruce DePalma worked by magnetic fields and this was it's downfall (because of the huge magnetic field it generated) saying a capacitive setup is much more preferable

RauiLast edited by Raui; 06-05-2010, 04:14 AM.

Leave a comment:

-

Did a bit more playing. Put about 0.5 ohms inline and put a scope on it. Peaked out at well over 8 amps and 400vac....yikes. Blue trace is across inductor. Yellow trace is across resistor.

Now we gotta figure out how to regulate it.Attached Files

Leave a comment:

Leave a comment: