Originally posted by gadh

View Post

Originally posted by gadh

View Post

Originally posted by gadh

View Post

Originally posted by gadh

View Post

Originally posted by gadh

View Post

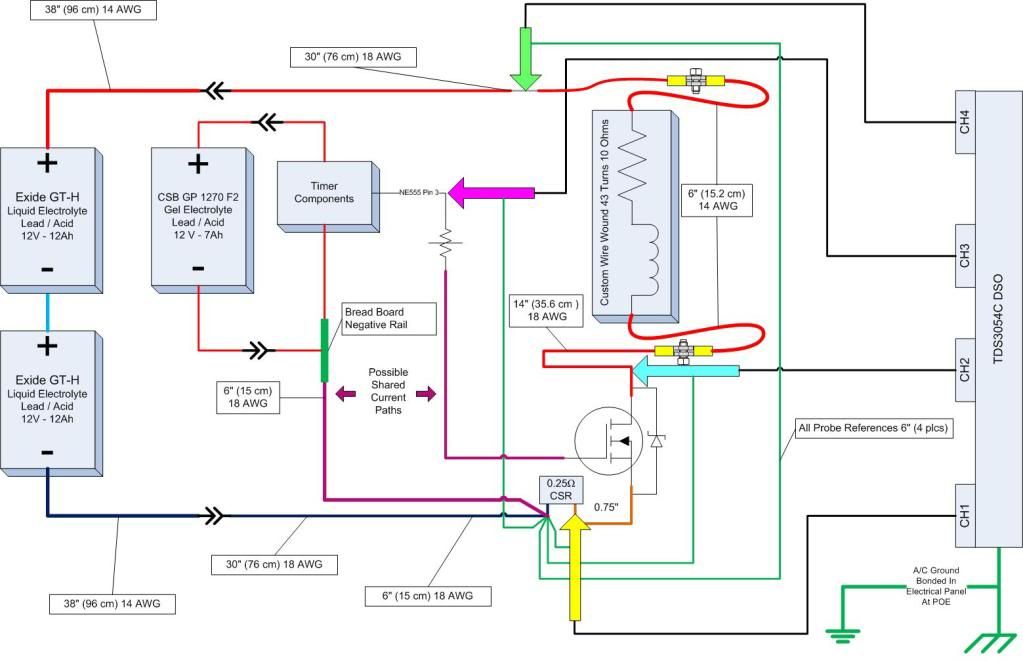

Hope that helps Gad. Sorry we're not replying quicker. I actually Skyped you on this but I think you didn't notice. Let me know about that wire.

EDITED

Comment