Hello,

quick intro (new here): I have always loved tinkering with electricity projects. I used to build pretty complex LED light fixtures for reef aquariums, so I have some minor understanding of things. Anyway, since I’ve gotten rid of my reef tanks I’ve wanted to keep up my electricity tinkering and thought I’d start with a Bedini.

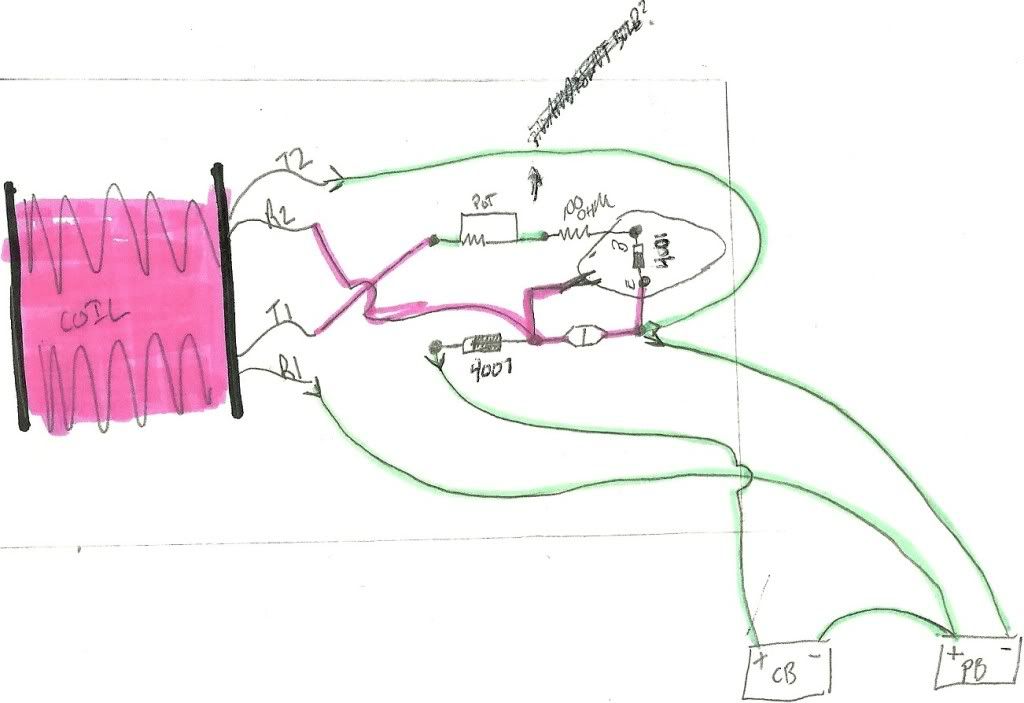

So I’ve built the circuit but it’s not working yet….and I have a few idea’s why….but I wanted to ask a couple things that I can’t seem to find the answer to online to help trouble shoot. I’ll probably rebuild my rotor, and then the coil also if that doesn’t work things out. So here’s the questions…

1) Does the size of the magnet affect rotation? For example I have some pretty big Neo’s and a pretty small coil. The neo’s are about 3” diameter and 1/4” thick (think they’re N35’s). The coil core is about 1/2” diameter (copper coated steel welding rods), and the coil OD is about 2.5” diameter. 26 awg and 30 awg. About 800 turns.

2) What should the coil’s ohms be when measured?

3) How important is bearing or rotor friction? I.e. can the rotor be a little stiff? I’m using some cheap $1.50 bearings and don’t really want to spend $20 on some German ones.

4) Is there a guideline or way to test for optimum magnet spacing?

5) Will more coils increase the torque potential of the rotor?

6) lastly what's the correct way to wire a 5 pin potentiometer for this application? or should I just go get a 3 pin?

Thanks.

quick intro (new here): I have always loved tinkering with electricity projects. I used to build pretty complex LED light fixtures for reef aquariums, so I have some minor understanding of things. Anyway, since I’ve gotten rid of my reef tanks I’ve wanted to keep up my electricity tinkering and thought I’d start with a Bedini.

So I’ve built the circuit but it’s not working yet….and I have a few idea’s why….but I wanted to ask a couple things that I can’t seem to find the answer to online to help trouble shoot. I’ll probably rebuild my rotor, and then the coil also if that doesn’t work things out. So here’s the questions…

1) Does the size of the magnet affect rotation? For example I have some pretty big Neo’s and a pretty small coil. The neo’s are about 3” diameter and 1/4” thick (think they’re N35’s). The coil core is about 1/2” diameter (copper coated steel welding rods), and the coil OD is about 2.5” diameter. 26 awg and 30 awg. About 800 turns.

2) What should the coil’s ohms be when measured?

3) How important is bearing or rotor friction? I.e. can the rotor be a little stiff? I’m using some cheap $1.50 bearings and don’t really want to spend $20 on some German ones.

4) Is there a guideline or way to test for optimum magnet spacing?

5) Will more coils increase the torque potential of the rotor?

6) lastly what's the correct way to wire a 5 pin potentiometer for this application? or should I just go get a 3 pin?

Thanks.

Comment