@HMS-776

You are right - this was what i was talking about in my description of EM fields in the WFC - the principle is the same, the only differance is the conditions for the result.

Thanks for a good post!

You are right - this was what i was talking about in my description of EM fields in the WFC - the principle is the same, the only differance is the conditions for the result.

Thanks for a good post!

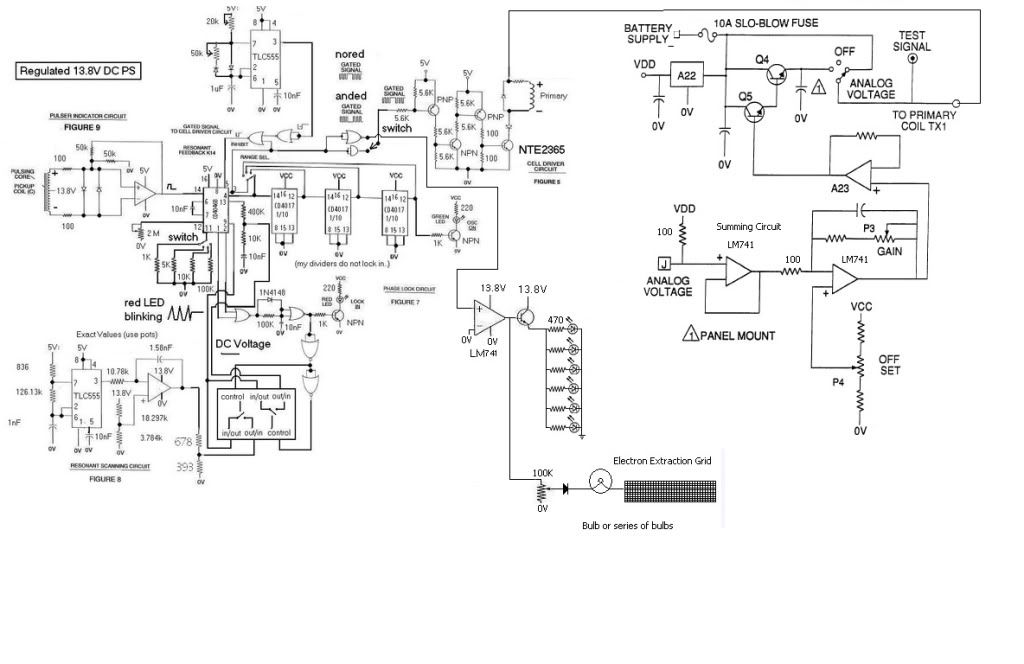

you can read with your eyes here:

you can read with your eyes here:

Comment