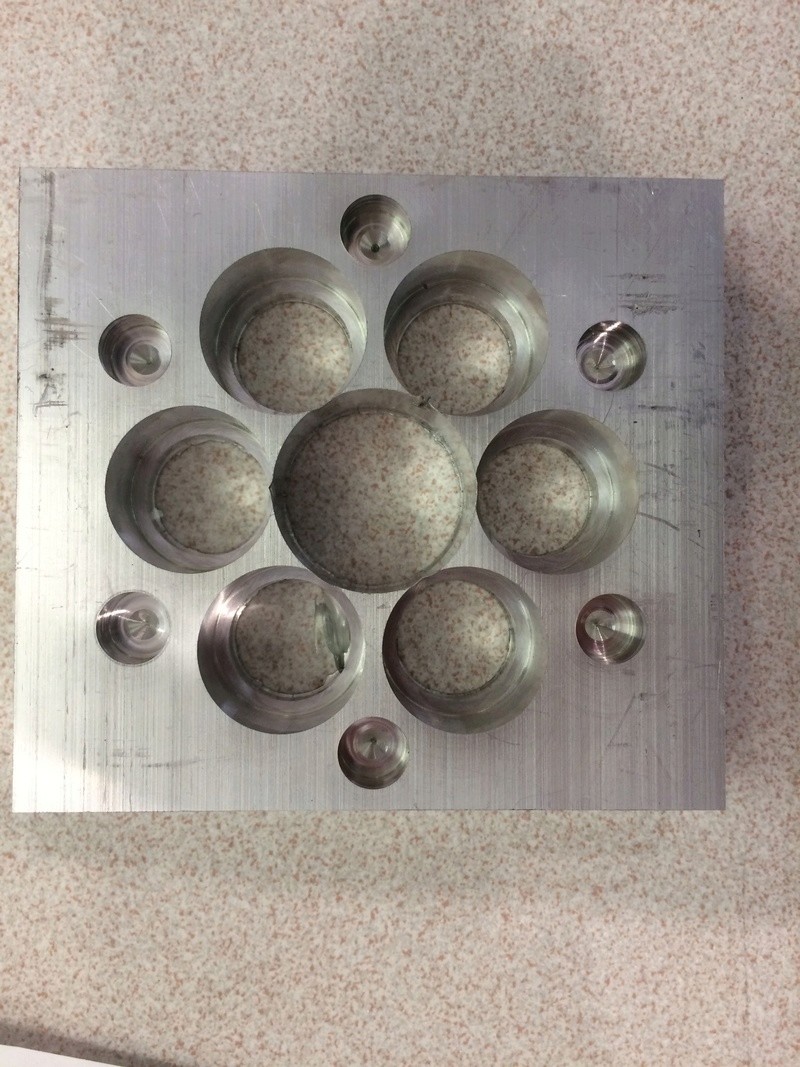

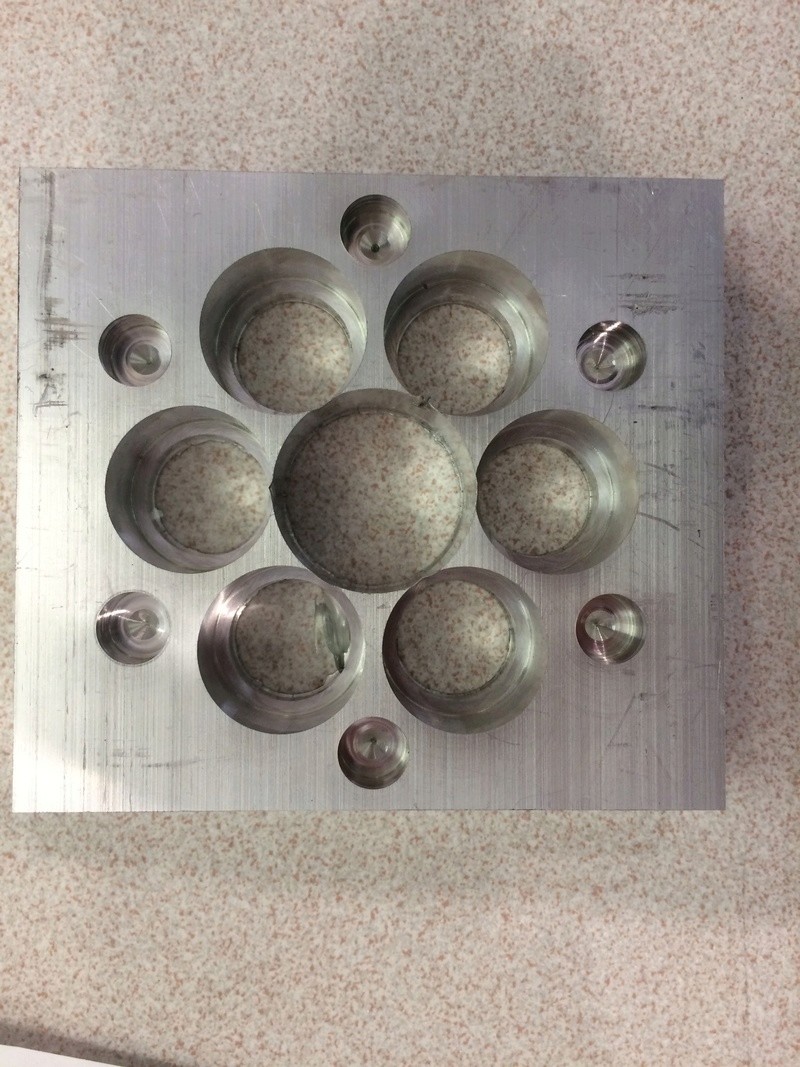

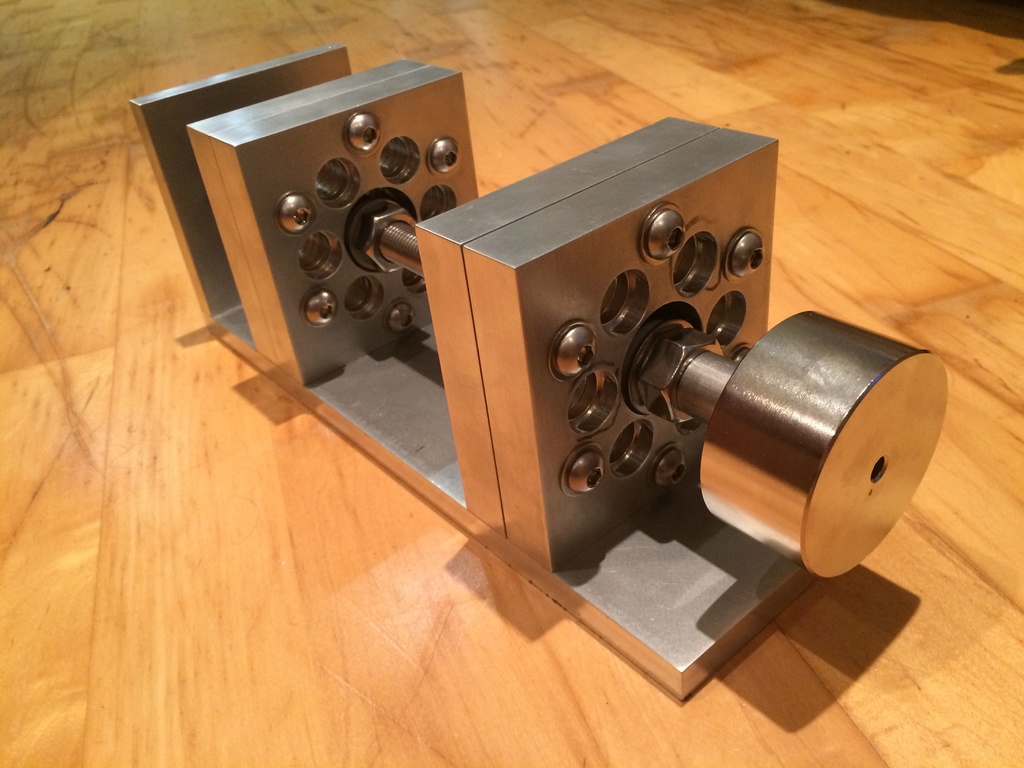

A little bit of progress, the engineering company have manufactured a mock up of one of the four magnet bearing caps.

Each bearing cap holds 18 x N52 grade neodymium ring magnets 22.9mm OD x 4.9mm thickness x 16mm ID

So 36 magnets per end of shaft.

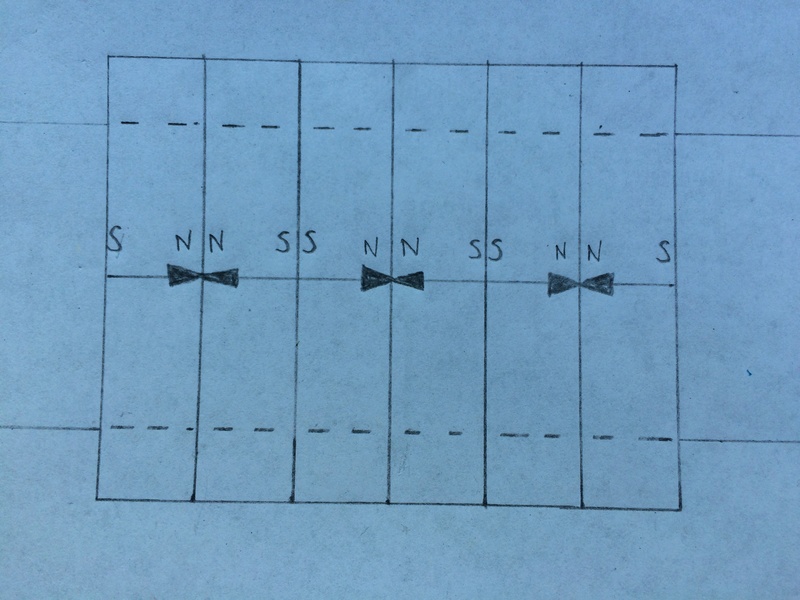

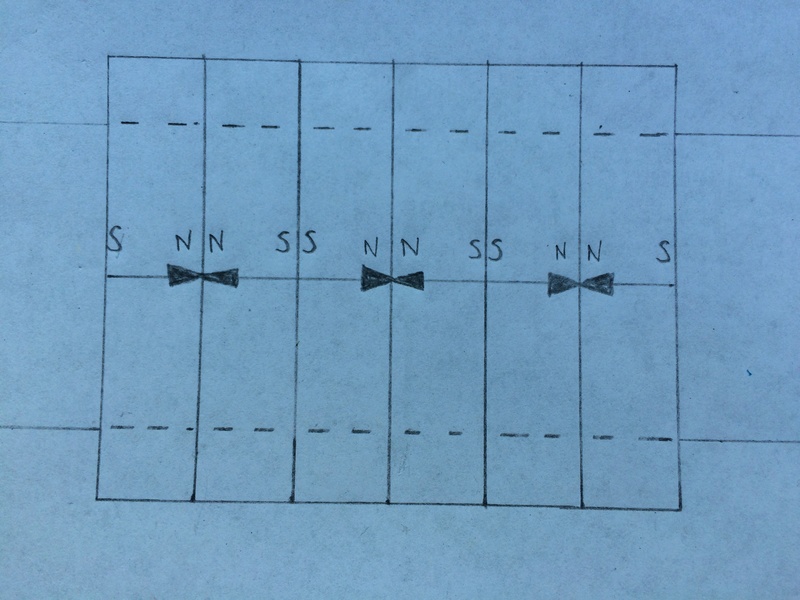

The magnets will be arranged like this:

6 x 6 magnets all in repulsion.

I have already designed numerous ways of ensuring they overcome Earnshaw's Theorum. Just got to figure out the best way. In my head this is arranging the array with North and South, North and South, North and South in a loop on all four magnet caps.

The gap on this magnet gap around the shaft is currently 2.45mm

Myself and the engineering company have agreed to increase this to 5mm to allow more tolerance.

All 6 holes are going to be broached so the magnets are exposed.

The shaft magnets are to be held in place and in repulsion by using a shaft made from threaded bar.

Two threaded collars allow the magnets to be positioned and held in repulsion to the same pattern.

The magnet end caps will be bolted together and the magnets guided with 16mm shafts.

These magnets are very powerful for their size.

I estimate the shaft should hold 20kg minimum in levitation without deviation.

Each bearing cap holds 18 x N52 grade neodymium ring magnets 22.9mm OD x 4.9mm thickness x 16mm ID

So 36 magnets per end of shaft.

The magnets will be arranged like this:

6 x 6 magnets all in repulsion.

I have already designed numerous ways of ensuring they overcome Earnshaw's Theorum. Just got to figure out the best way. In my head this is arranging the array with North and South, North and South, North and South in a loop on all four magnet caps.

The gap on this magnet gap around the shaft is currently 2.45mm

Myself and the engineering company have agreed to increase this to 5mm to allow more tolerance.

All 6 holes are going to be broached so the magnets are exposed.

The shaft magnets are to be held in place and in repulsion by using a shaft made from threaded bar.

Two threaded collars allow the magnets to be positioned and held in repulsion to the same pattern.

The magnet end caps will be bolted together and the magnets guided with 16mm shafts.

These magnets are very powerful for their size.

I estimate the shaft should hold 20kg minimum in levitation without deviation.

Comment